Pattern structure for electronic component and manufacturing method of pattern structure

A technology of electronic components and manufacturing methods, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, microstructure technology, etc., can solve problems such as discontinuity of film layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

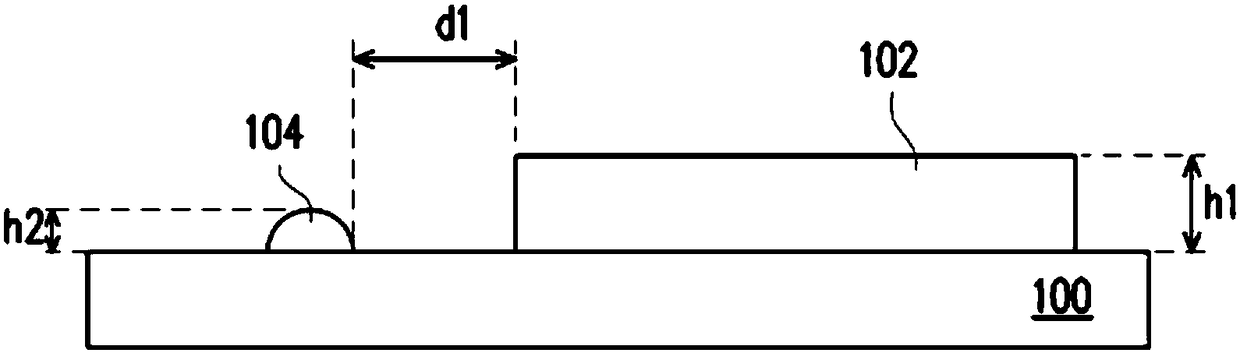

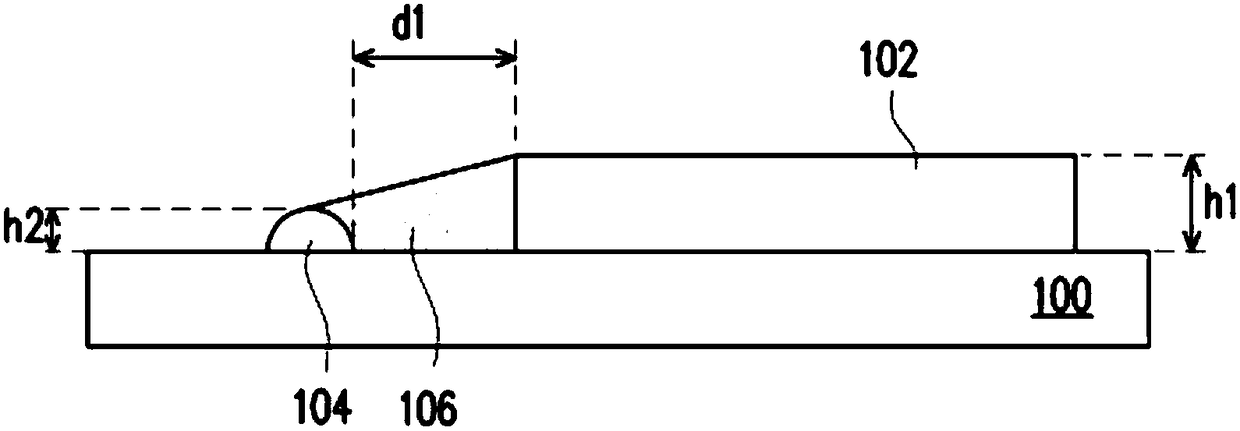

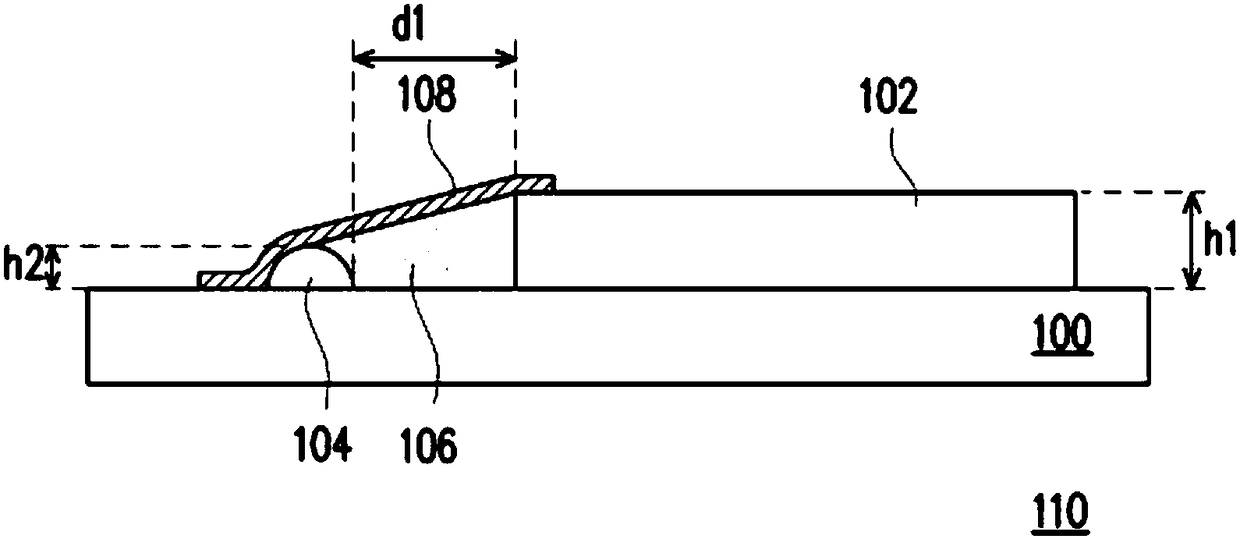

[0022] Figure 1A to Figure 1C is a schematic cross-sectional view of the manufacturing process of the pattern structure according to an embodiment of the present invention.

[0023] Please refer to Figure 1A , the manufacturing method of the pattern structure of this embodiment is used for electronic components, which includes the following steps. Firstly, a pattern layer 102 is formed on the substrate 100 . In an embodiment, the substrate 100 may include a semiconductor substrate, a glass substrate or a flexible substrate. The pattern layer 102 can be a thin film made of any material, and the pattern layer 102 can also be a semiconductor component or a die. The present invention is not limited to the types of the substrate 100 and the pattern layer 102 . The thickness h1 of the pattern layer 102 may be greater than 200 nm. If a film layer (layer) is directly formed on the pattern layer 102 by inkjet printing, the step height between the pattern layer 102 and the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com