Self-energy-acquisition inner pipe wall cleaning robot

An inner wall cleaning and robot technology, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of complex structure, incomplete cleaning and low work efficiency of inner wall cleaning robots, and reduce the structure of transmission lines. Design, compact structure, easier removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

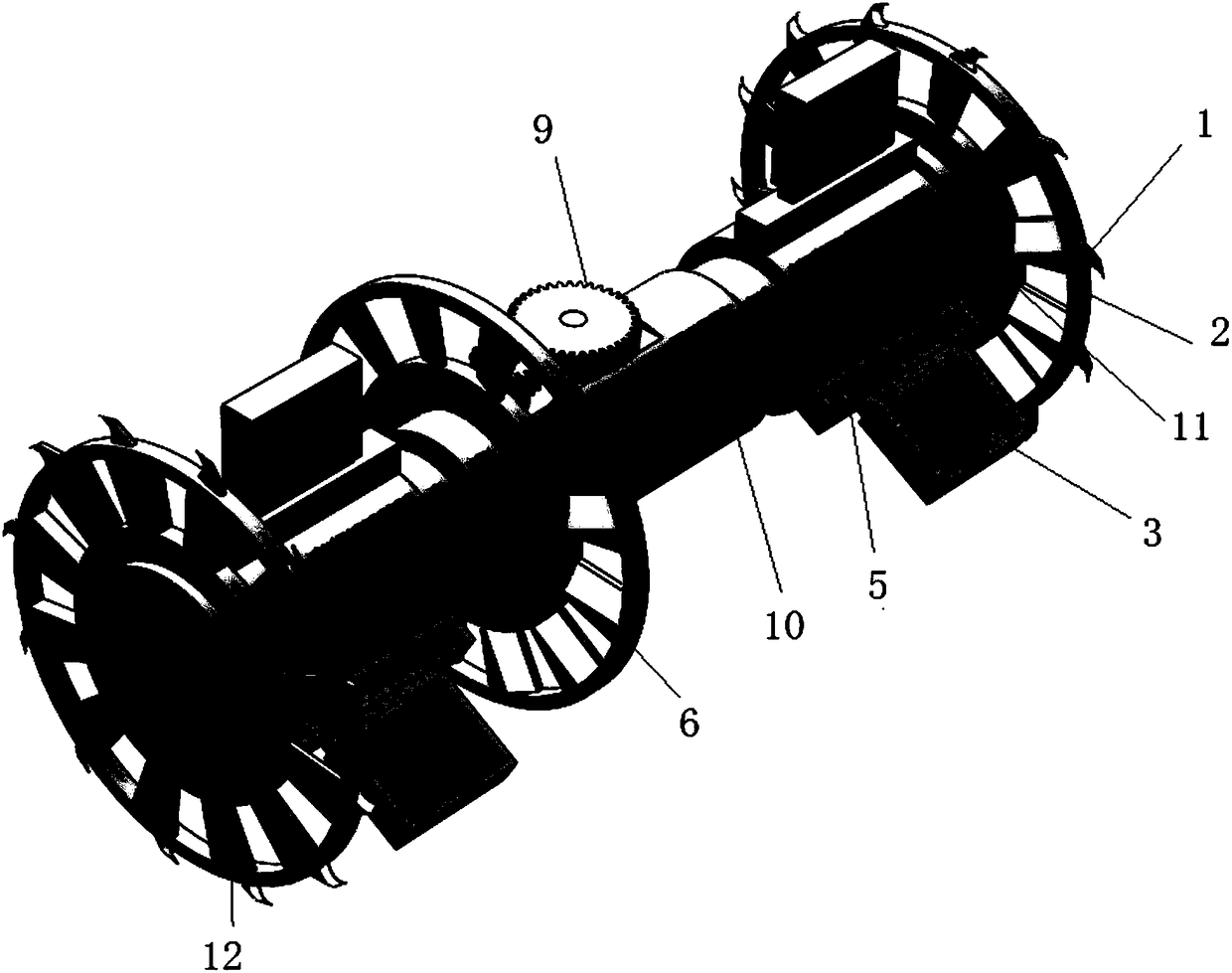

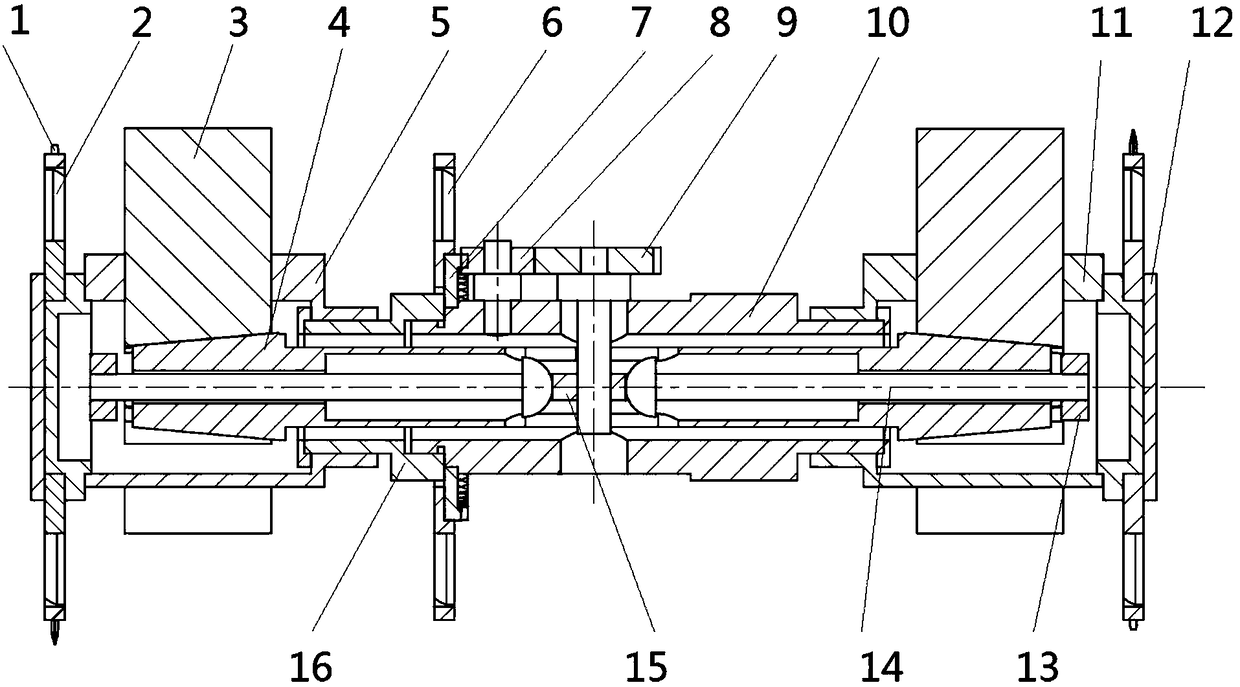

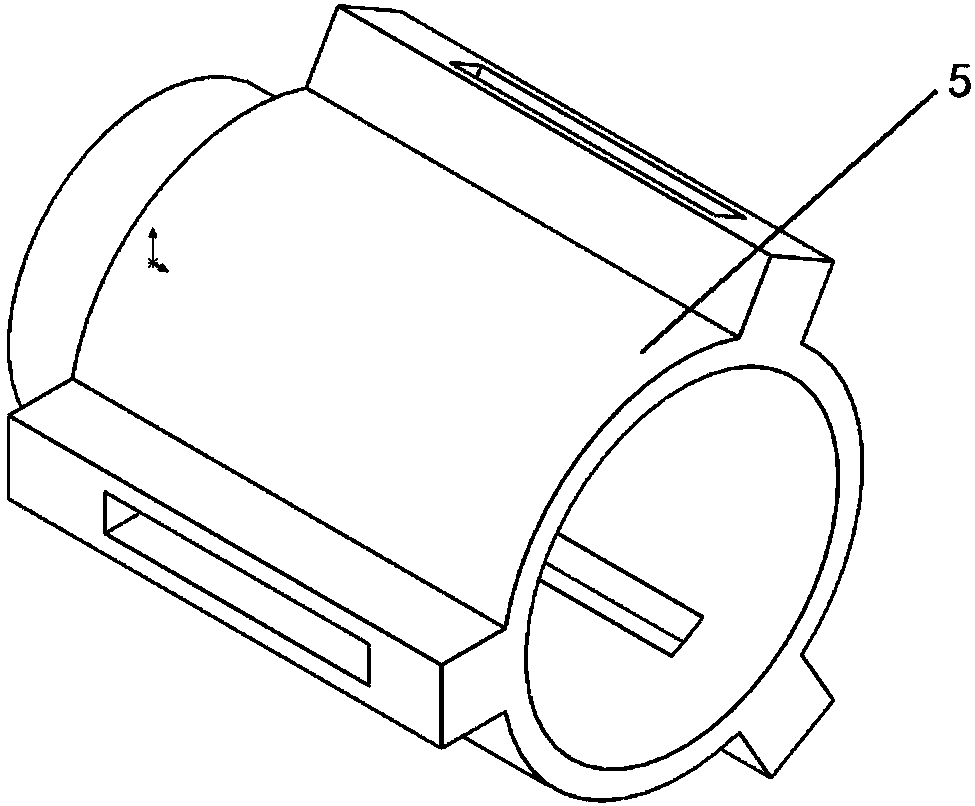

[0023] Such as figure 1 Shown is a cleaning robot for self-energy pipeline inner wall, the robot includes: cleaning plate 1, cleaning tool 2, support foot 3, inner shaft 4, support sleeve 5, drive plate 6, crown gear 7, pinion gear 8, large gear 9. Shaft sleeve 10, inner end cap 11, outer end cap 12, magnet 13, push rod 14, cam 15 and inner shaft sleeve 16. The two support sleeves 5 are arranged at both ends of the shaft sleeve 10 through the inner shaft sleeve 16, and the two cleaning discs 1 are respectively arranged at the two ends of the two support sleeves 5 through respective inner end caps 11 and outer end caps 12; The cleaning tool 2 is embedded in the cleaning disc 1 through a spring; the inner shaft 4 is installed inside the bushing 10; it is located at both ends of the bushing 10, between the two cleaning discs 1, and a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com