Automated production method and production equipment for double steel plate shear wall components

A production method and shear wall technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as inability to form standardization, achieve the effects of solving aging problems, increasing profit margins, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Split the double-plate shear walls of various shapes into inline double-plate shear walls, and further split the inline double-plate shear walls exceeding the transportation width into inline double-plate shear walls whose width meets the transportation requirements;

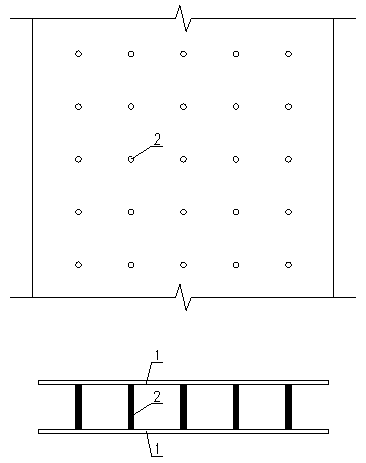

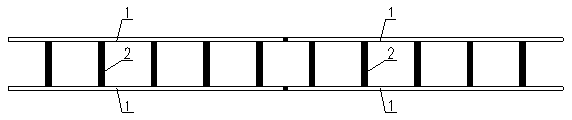

[0058] The inline double-steel plate shear wall whose width meets the requirements includes at least one double-steel plate shear wall unit, and the double-steel plate shear wall unit is composed of steel plates (1) on both sides and intermediate connectors (2);

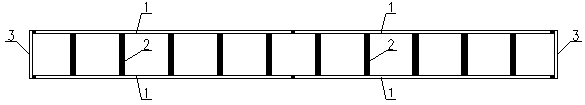

[0059] Connect the double steel plate shear wall unit production equipment with the in-line double steel plate shear wall component internal rod splicing equipment, and produce multiple double steel plate shear wall units, or combine the produced double steel plate shear wall units with The end steel plates (3) or / and the intermediate through-length stiffeners (4) are positioned and fixed, and then welded;

[0060] The end steel plate (3) and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com