Cooling device for digging robot

A cooling device and robot technology, applied in manipulators, mining equipment, tunnels, etc., can solve problems such as inability to meet heat dissipation requirements, achieve rapid and efficient cooling, speed up fan blade rotation, and improve heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

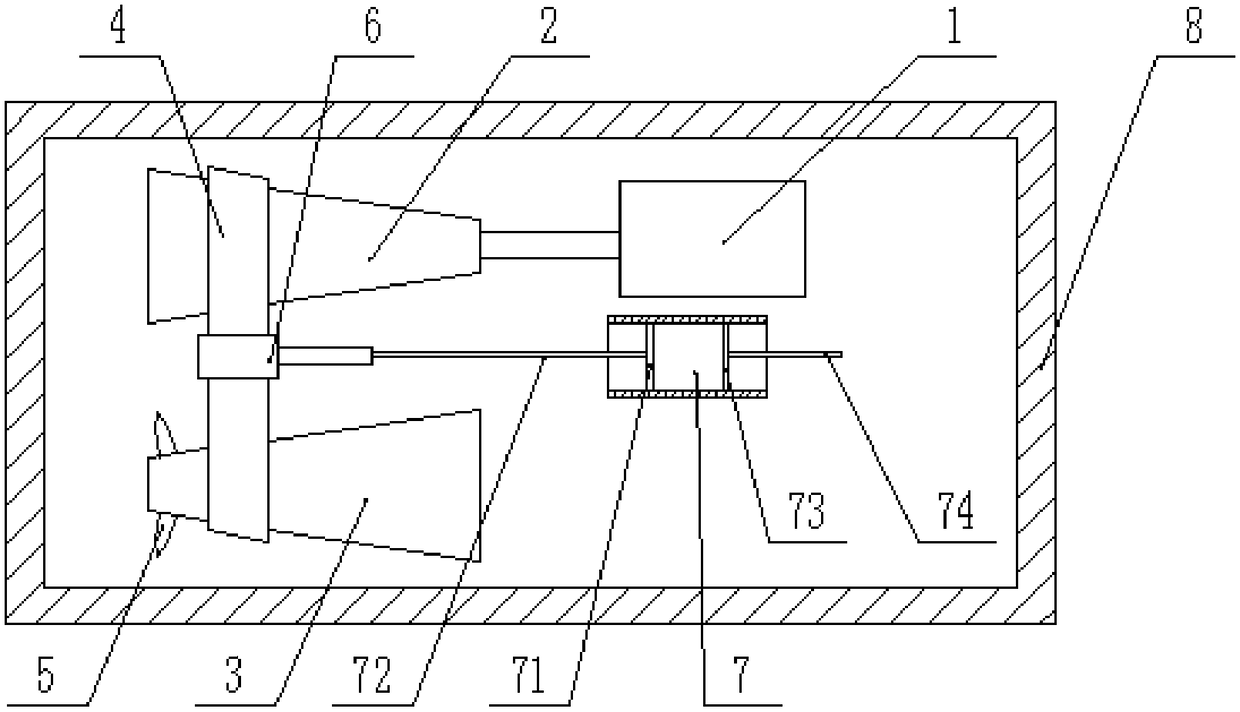

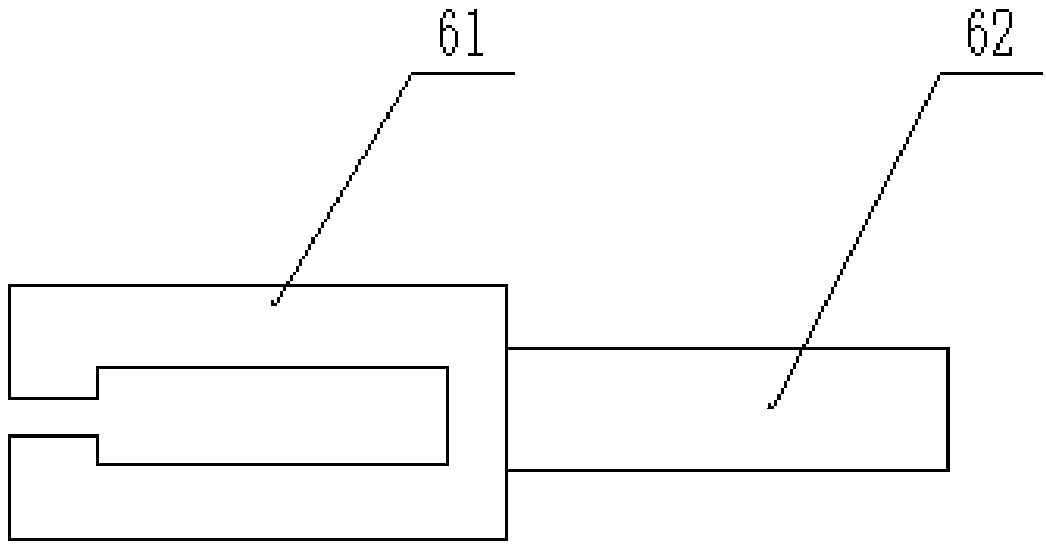

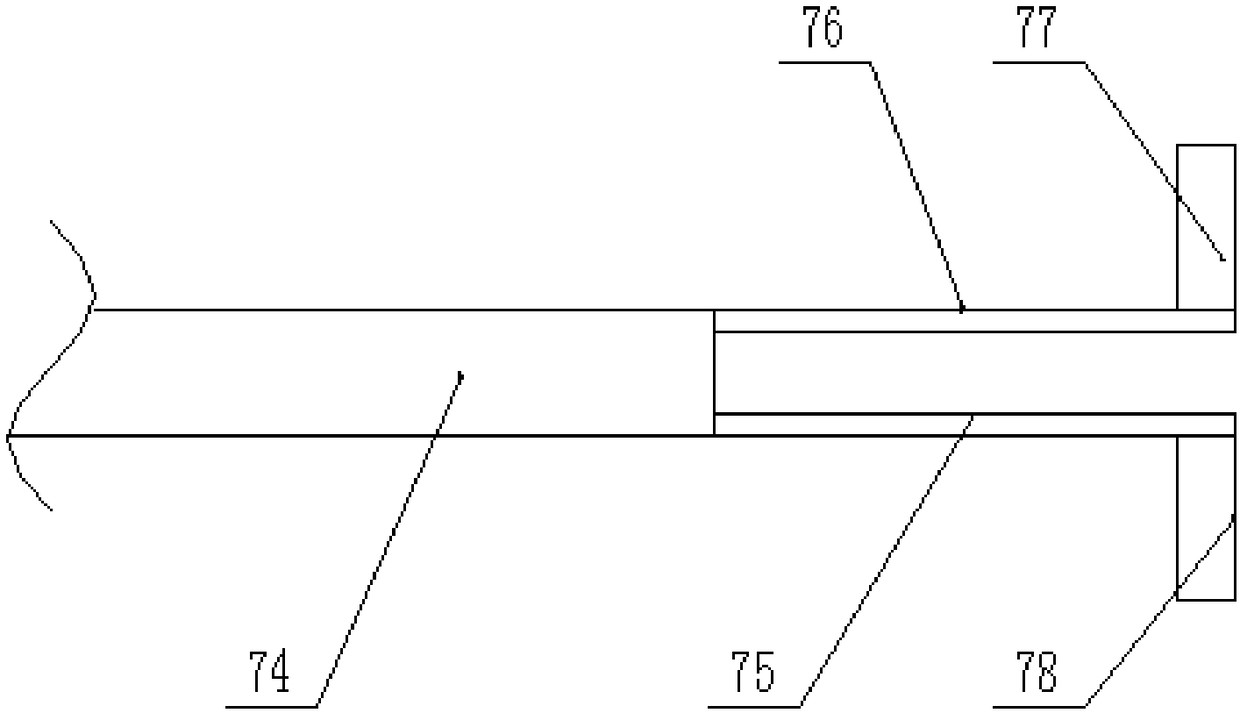

[0022] The reference signs in the drawings of the description include: engine 1, first rotating shaft 2, second rotating shaft 3, belt 4, fan blade 5, shift fork 6, snap-in section 61, connecting section 62, sleeve 7, first piston 71. The first piston rod 72, the second piston 73, the second piston rod 74, the first push rod 75, the second push rod 76, the second baffle plate 77, the first baffle plate 78, and the cooling box 8.

[0023] Such as figure 1 As shown, a cooling device for an excavating robot includes a cooling box 8 located in the body of the excavating robot. The first rotating shaft 2 in the shape of a circular platform is rotatably connected to the cooling box 8, and the bottom of the first rotating shaft 2 in the cooling box 8 is rotatably connected to a The first rotating shaft 2 has the same size as the second rotating shaft 3, the left side of the first rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com