Modified water purification sludge loaded nanometer zero-valent iron material and its preparation method and application

A nano-zero valent iron, water purification technology, applied in water/sludge/sewage treatment, water pollutants, water/sewage treatment, etc., can solve problems such as high cost and unenvironmental protection, and achieve high reactivity and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

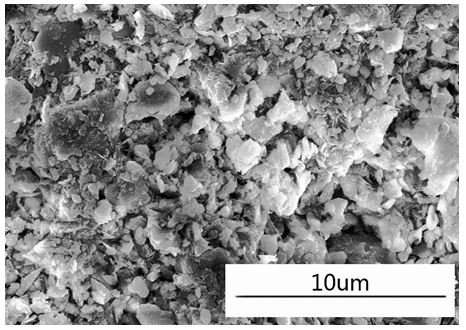

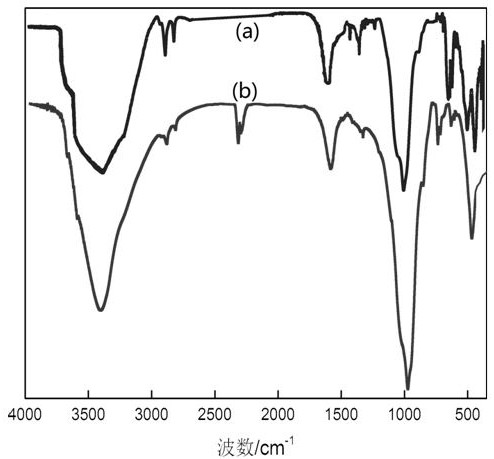

[0034] A nanometer zero-valent iron material loaded with modified water purification sludge, the specific production steps are as follows:

[0035] Place the fresh water purification sludge in a blast oven at 120°C for 12 hours, grind it through a mesh sieve, and select water purification sludge particles with an average particle size of 100 microns for use; take a certain quality of spare water purification sludge particles and place them at 500°C Calcined in a muffle furnace for 3 hours, transferred to 3mol / L HCl solution and soaked for 10 hours after cooling, took out the water purification sludge, washed it with distilled water until neutral and dried to obtain modified water purification sludge;

[0036] The configuration concentration is 1mol / L NaBH 4 Solution, according to the solid-liquid ratio of 1:60, the concentration is 0.3 mol / L Fe(NO 3 ) 3 •9H 2 O solution was added with modified water purification sludge and shaken for 310 min at room temperature at 25°C to o...

Embodiment 2

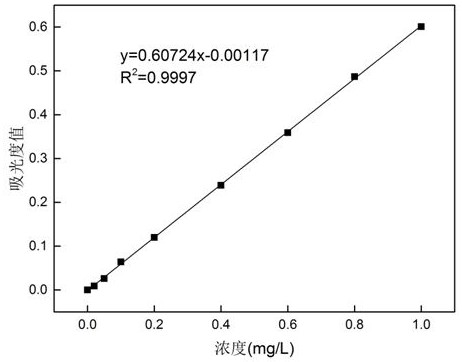

[0040] The modified water purification sludge loaded nano-zero-valent iron material has a strong removal effect on Cr(VI) in the water body. When the Cr(VI) concentration in the water body is 20mg / L, the modified water purification sludge loaded with nano After the zero-valent iron material was shaken for 3.5 hours, the concentration of Cr(VI) dropped to 0.8mg / L, and the removal rate reached 96%. The following is the experimental scheme for removing Cr(VI) from water by loading nanometer zero-valent iron on modified water purification sludge.

[0041] 1. Experimental equipment and reagents

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com