A Compensation Method for Robot Bending Accuracy Based on Sheet Metal Tensile Deformation

A tensile deformation and precision compensation technology, applied in the direction of instruments, simulators, computer control, etc., can solve the problem of low bending accuracy of robots, and achieve the effect of eliminating pulling or squeezing and improving bending accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

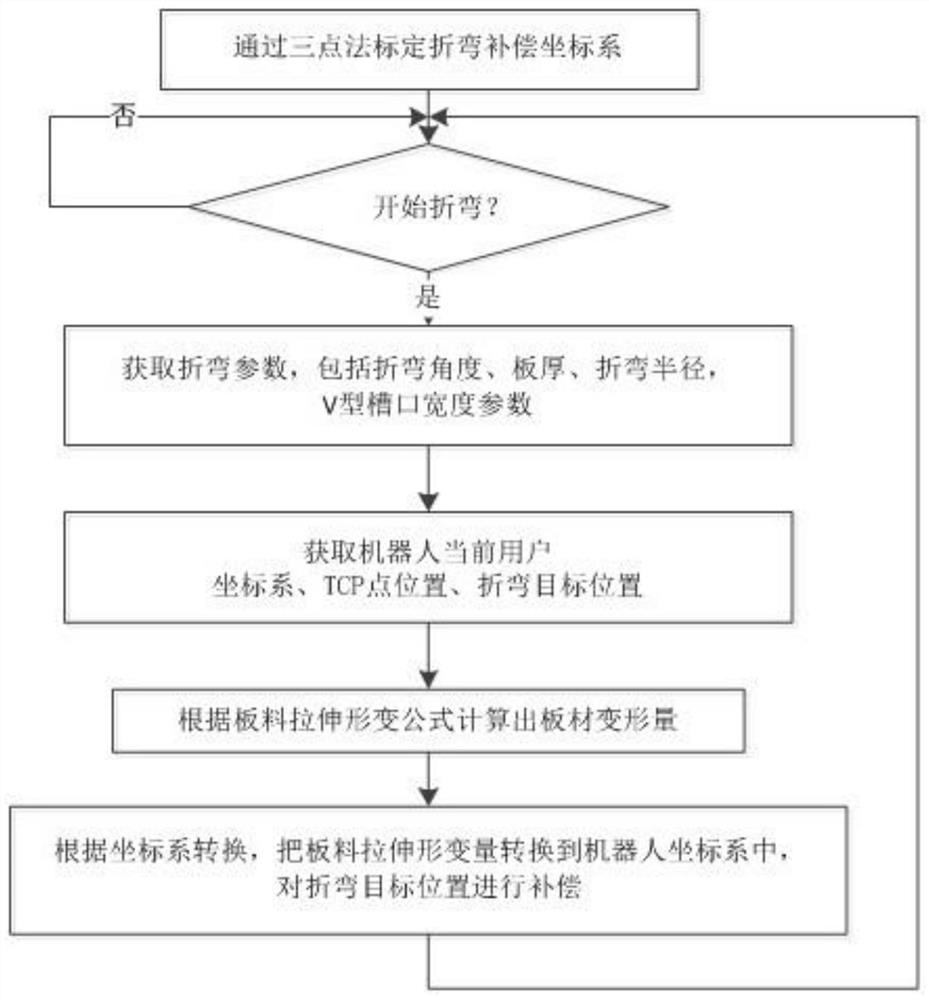

[0045] The present invention will be specifically described in connection with the examples and drawings.

[0046] The implementation steps are as follows:

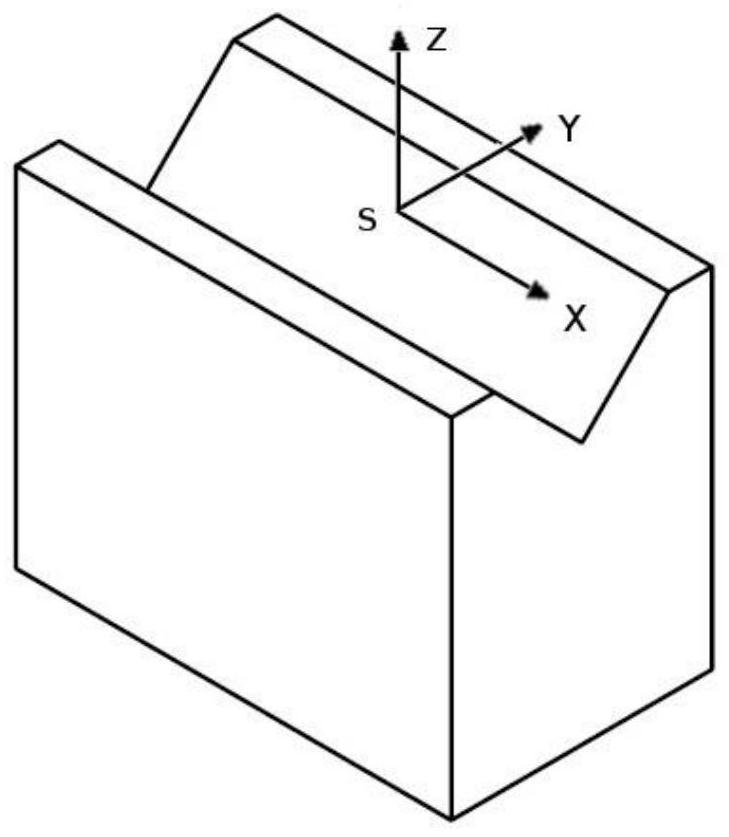

[0047] Step 1: Three points on the slot through the robot, the origin O coordinate value is P O (1896.72, -239.85, 1033.50), point P in the X-axis direction of the compensation coordinate system in the inlet direction A (1835.10, -1672.77, 1038.03), calibration compensation coordinate system xy flat direction point P B (1856.89, -1437.79, 1037.22), the X, Y, Z-axis unit vector of the compensation coordinate system is obtained, respectively, and the rotation matrix is as follows:

[0048]

[0049] According to the Z-Y-Z ELA conversion formula, by the rotary matrix R S The A = -92.46, b = 0, c = 0, thereby obtaining the compensation coordinate system as follows:

[0050] S = (1896.72, -239.85, 1033.50, -92.46, 0)

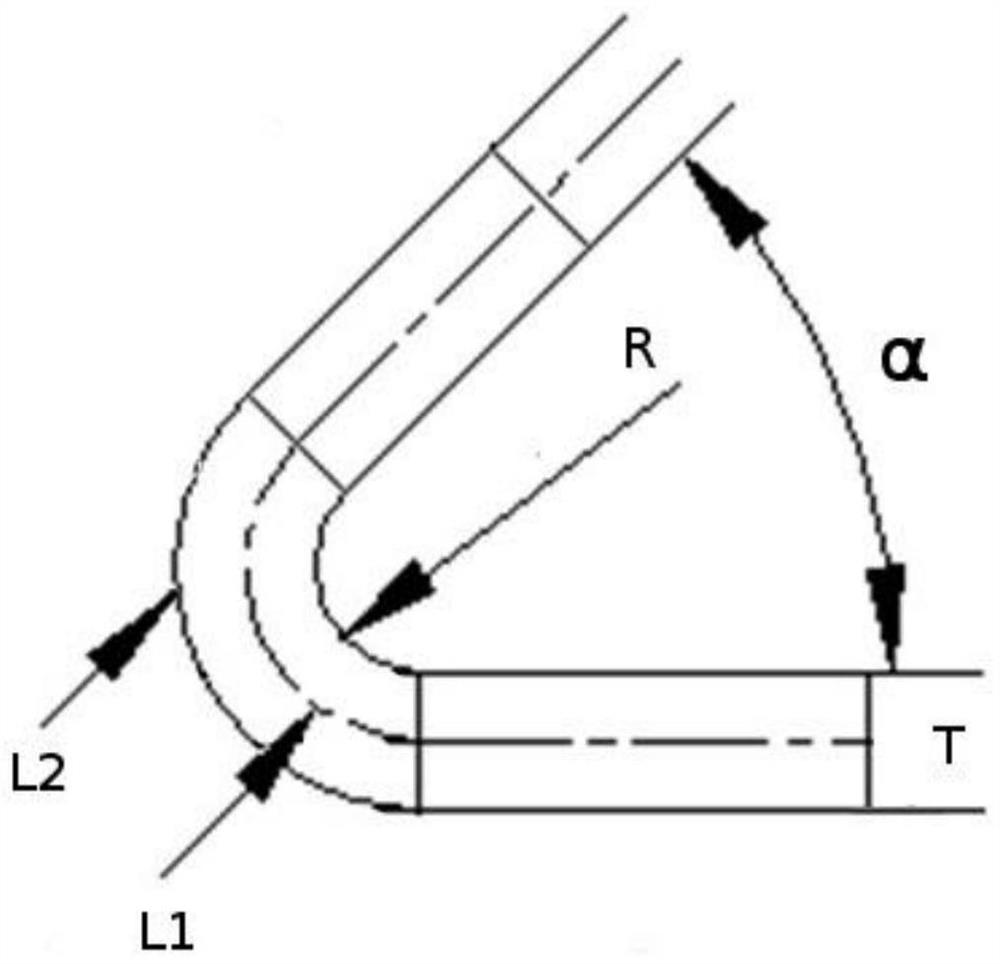

[0051] Step 2: Get the bending parameters, bending the angle α = 90o, the bend radius R = 1 mm, the plate thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com