Side chain device

A technology of side chain and driving sprocket, which is applied in the field of sandwich panel production equipment, can solve the problems of wear and tear of the chain 4, inability to play, and prone to tooth skipping, so as to reduce production costs and maintenance costs, eliminate free space, and ensure molding. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

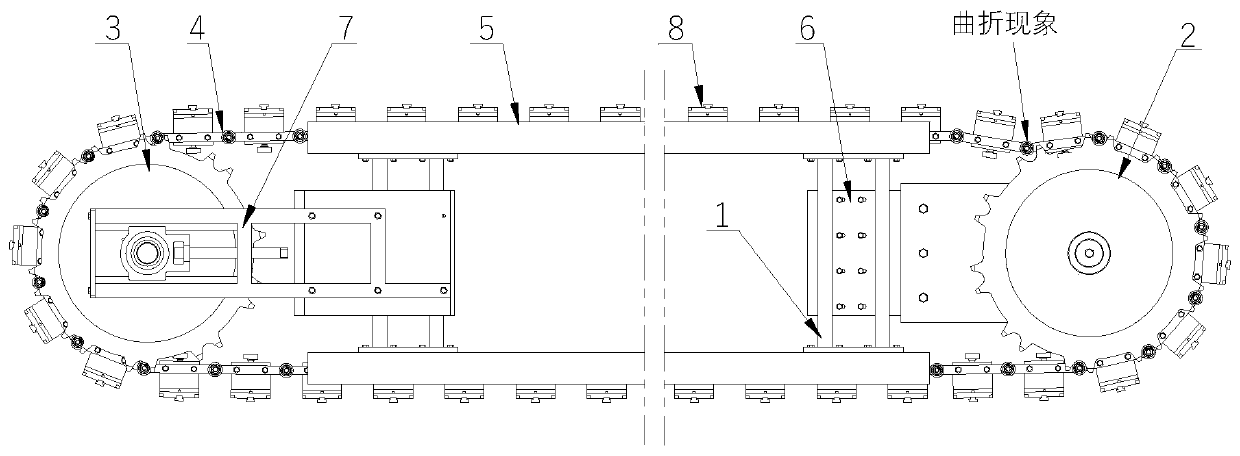

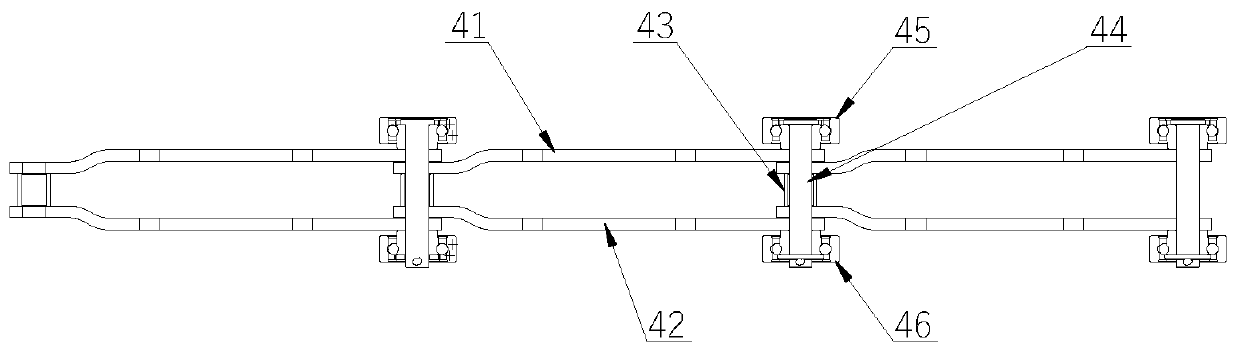

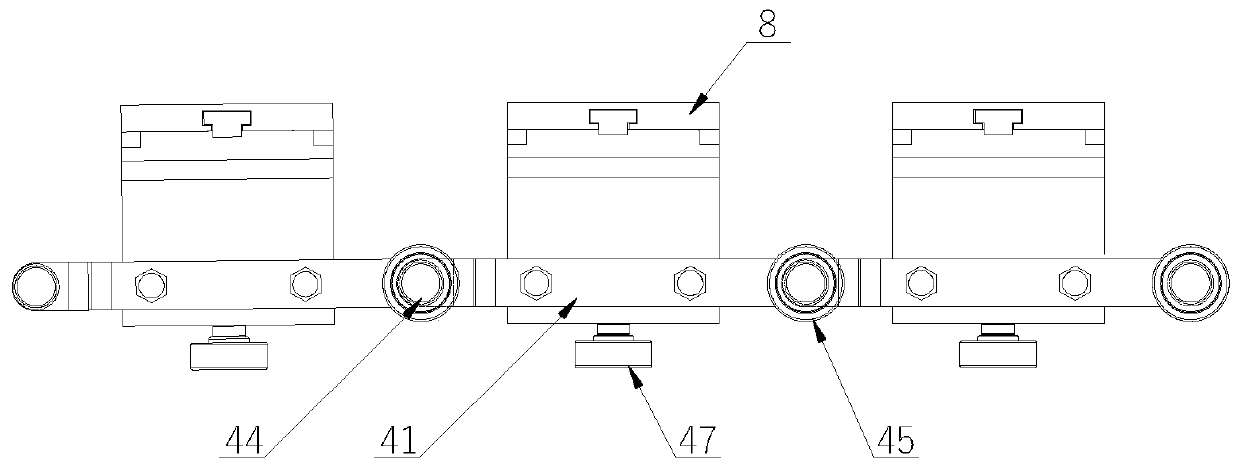

[0050] Such as Figure 4 A schematic diagram of a top view structure of a side chain device provided in an embodiment of the present invention is shown in the following:

[0051] A side chain device, used in the continuous production process of polyurethane color steel sandwich panels, to prevent polyurethane material liquid from flowing out of polyurethane color steel sandwich panels, to seal the edges of polyurethane color steel sandwich panels, and to overcome the polyurethane material liquid in the polyurethane color steel sandwich panels The lateral force generated during the foaming and curing process guides the movement of the polyurethane color steel sandwich panel in the double track laminator, including:

[0052] Frame 1, driving sprocket 2, driving system 6, guide rail 5, chain 4, side mold 8 and connecting plate 9;

[0053] The driving sprocket 2 and the driving system 6 are installed on the frame 1 respectively, and the driving system 6 drives the driving sprocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com