Cable seal and cable seal connector

A technology of cable sealing and connectors, which is applied in the direction of vehicle connectors, connections, electrical components, etc., can solve the problems of large outer diameter tolerance and cylindricity tolerance, and achieve the effects of improving production efficiency, reducing the risk of sealing failure, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

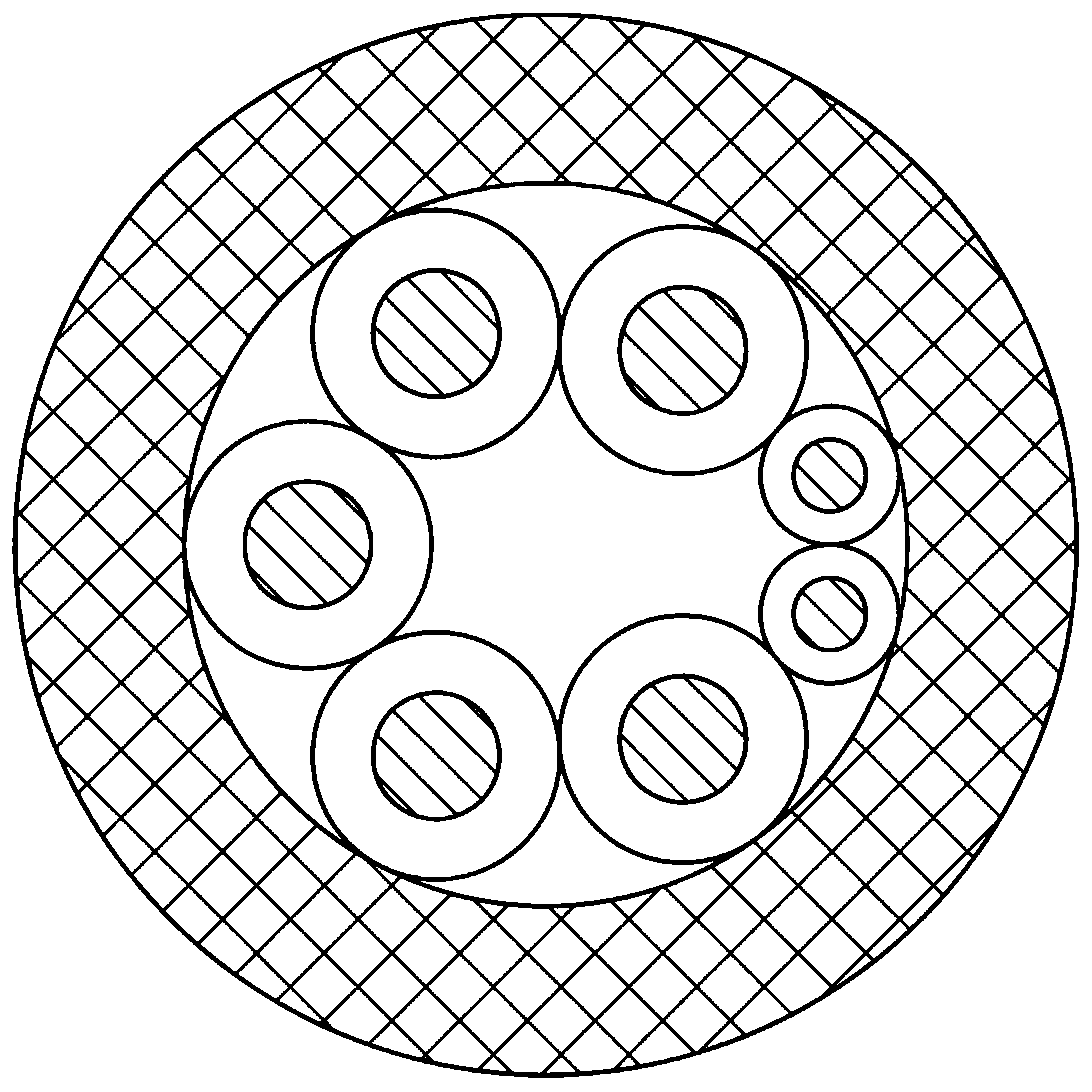

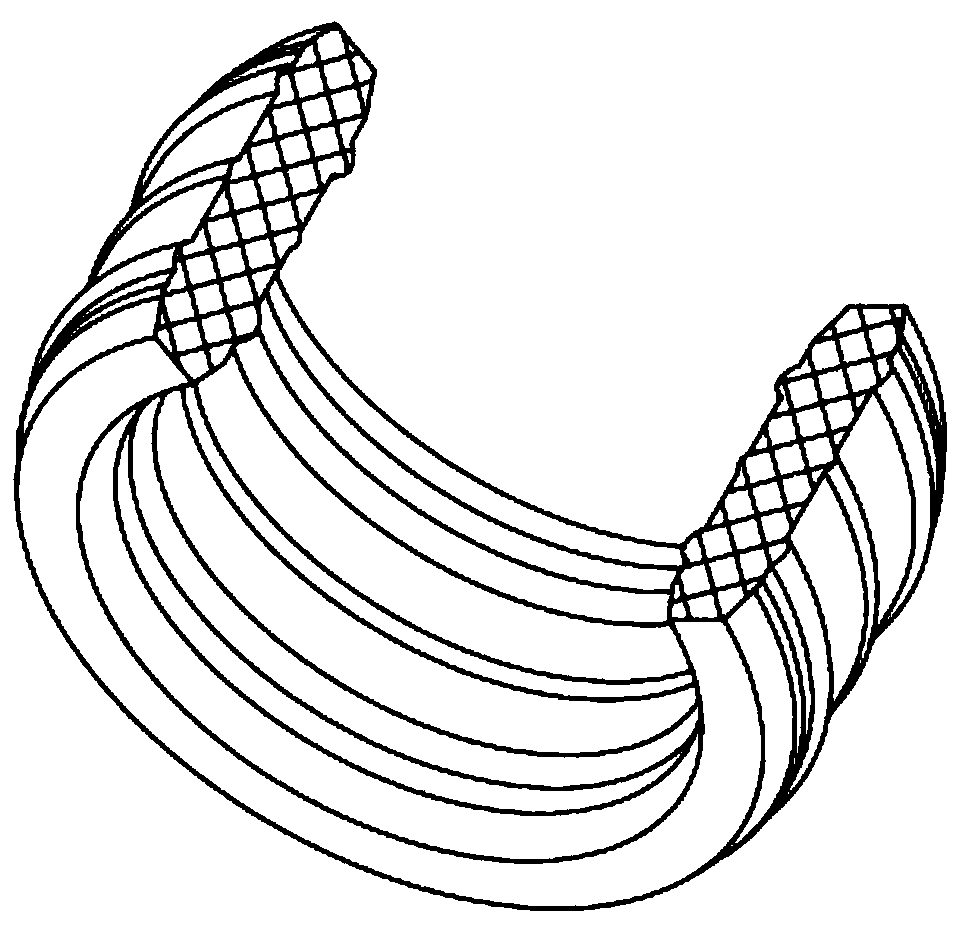

[0042] Such as Figure 4 As shown, the cable seal of this embodiment includes an annular elastic body, the inner peripheral portion of the annular elastic body is provided with at least one cable sealing ring 21 for abutting the cable, and the outer peripheral portion of the annular elastic body At least one housing sealing ring 23 for abutting against the housing of the connector is provided;

[0043] The outer peripheries of both ends of the annular elastic body are respectively provided with recesses 24 for packaging and filling.

[0044] The recess 24 on the cable seal forms a gap that can be filled with potting material when the cable seal connector is potted. refer to Figure 5 with Image 6 As shown, when the recess 24 is filled, its bottom, side, and both ends of the annular elastic body form a pressure receiving area, that is, the sealing ring obtains the packaging pressure, thereby ensuring that the sealing ring and the connector housing and the Seal reliability ...

Embodiment 2

[0046] Based on Example 1, combined with Figure 4 , Figure 5 with Image 6 As shown, in this embodiment, the bottom angle of the side near the axial center of the annular elastic body in the recessed portion 24 is an arc angle with a radian greater than 90 degrees. In this embodiment, the depth of the recessed portion of the sealing member gradually decreases from both ends of the annular elastic body inward, so that the annular elastic body is in an irregular step shape, which optimizes the force on the recessed portion when the package is filled, and makes the sealing effect better.

[0047] Such as Figure 4 As shown, in this embodiment, one cable sealing ring is provided at both ends of the inner peripheral portion of the annular elastic body, and three outer casing sealing rings are provided at the outer peripheral portion between the concave portions at both ends. The design of the recesses at the two ends of the outer ring and the plurality of sealing rings on the...

Embodiment 3

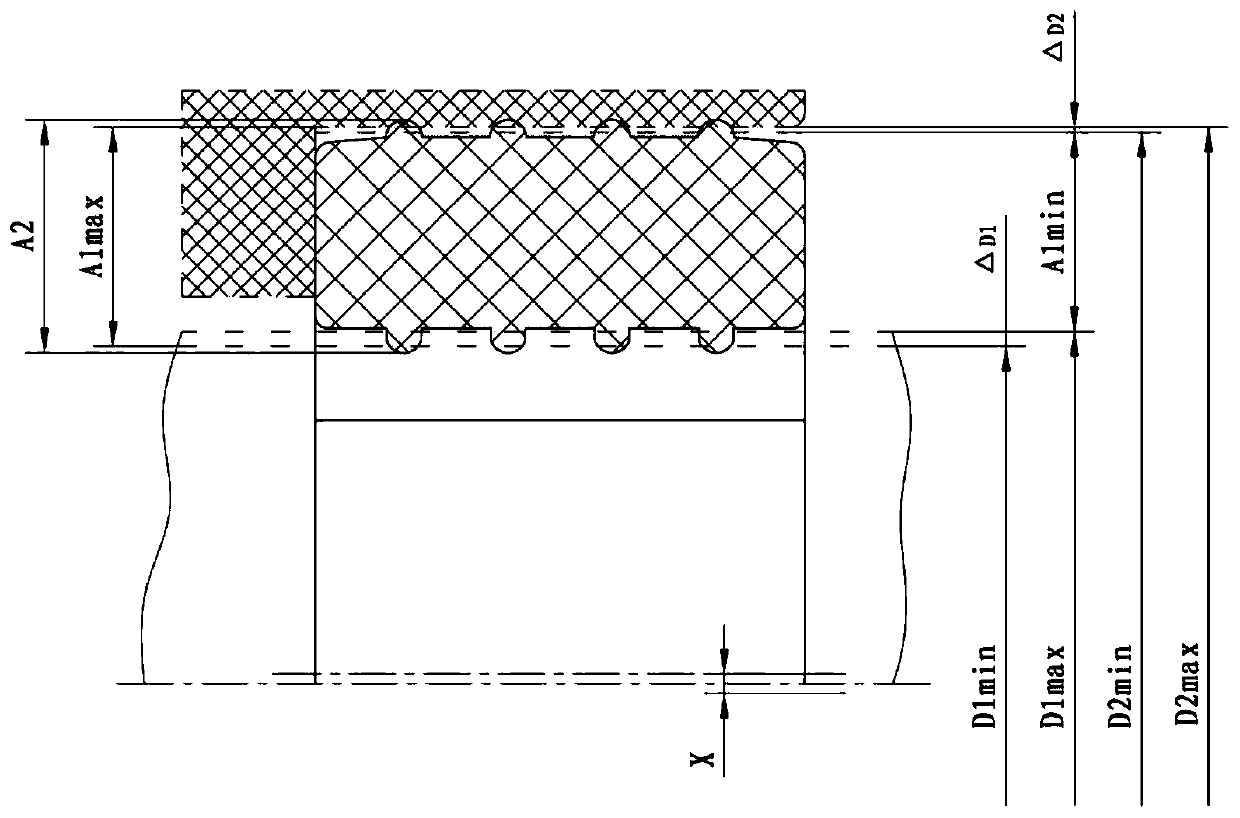

[0052] combine Figure 3 to Figure 9 , the cable sealing connector of the present invention includes a connector housing 1 and a connector body 6, one end of the connector body 6 is fixed in the connector housing 1, and this end and the end of the cable 5 are electrically connected in the connector housing 1. connect;

[0053] Also includes a cable seal 2, a cable clamp 3 and an enclosure 4;

[0054] The cable seal 2 is sheathed between the outer periphery of the cable 5 and the connector housing 1, and the inner circumference of the cable seal 2 is provided with at least one cable seal ring 21 that can contact the cable. At least one housing sealing ring 23 that can be abutted against the housing is provided on the peripheral part; recesses for sealing and filling are respectively provided on the outer peripheries of both ends of the cable sealing member.

[0055] combine image 3 , Figure 7 with Figure 8 , the cable clamp 3 is fixed on the outer periphery of the cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com