Apparatus and method for separating liquid from a material comprising a solid fraction and a liquid fraction

A technology for solid parts and equipment, applied in the field of equipment for separating liquids, can solve the problems of expensive liquids, increased weight, increased transportation costs, cleaning costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Hereinafter, position indications such as "upper", "lower", "right" and "left" refer to positions shown in the drawings.

[0064] Identical or corresponding elements in different figures are identified by the same reference numerals.

[0065] It will be understood by those skilled in the art that the drawings are schematic only and that relative proportions between various elements may be distorted.

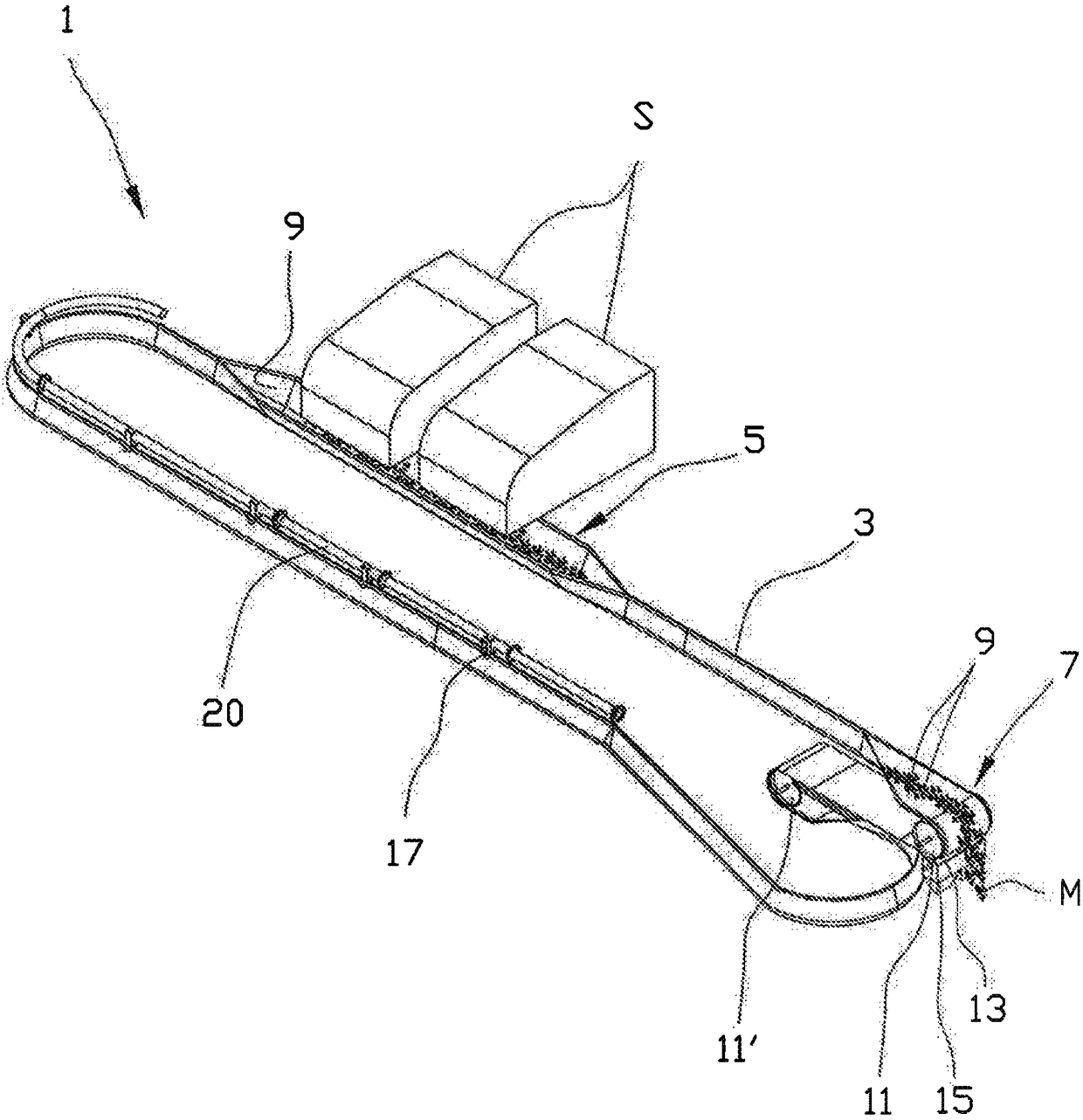

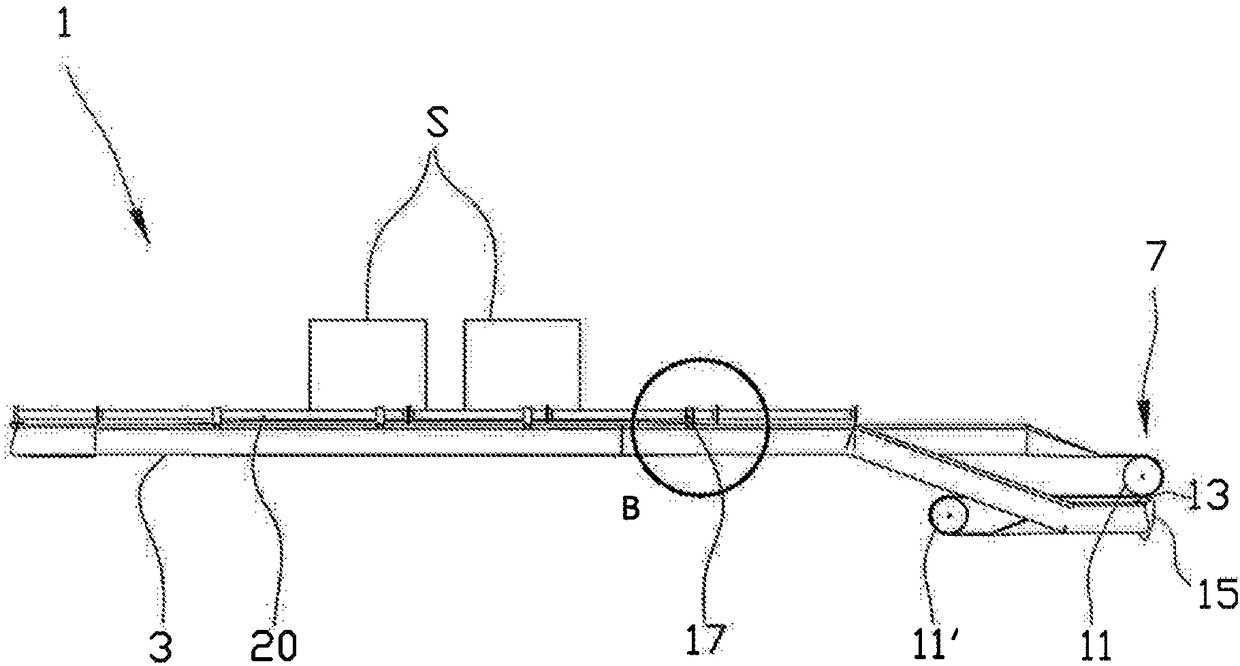

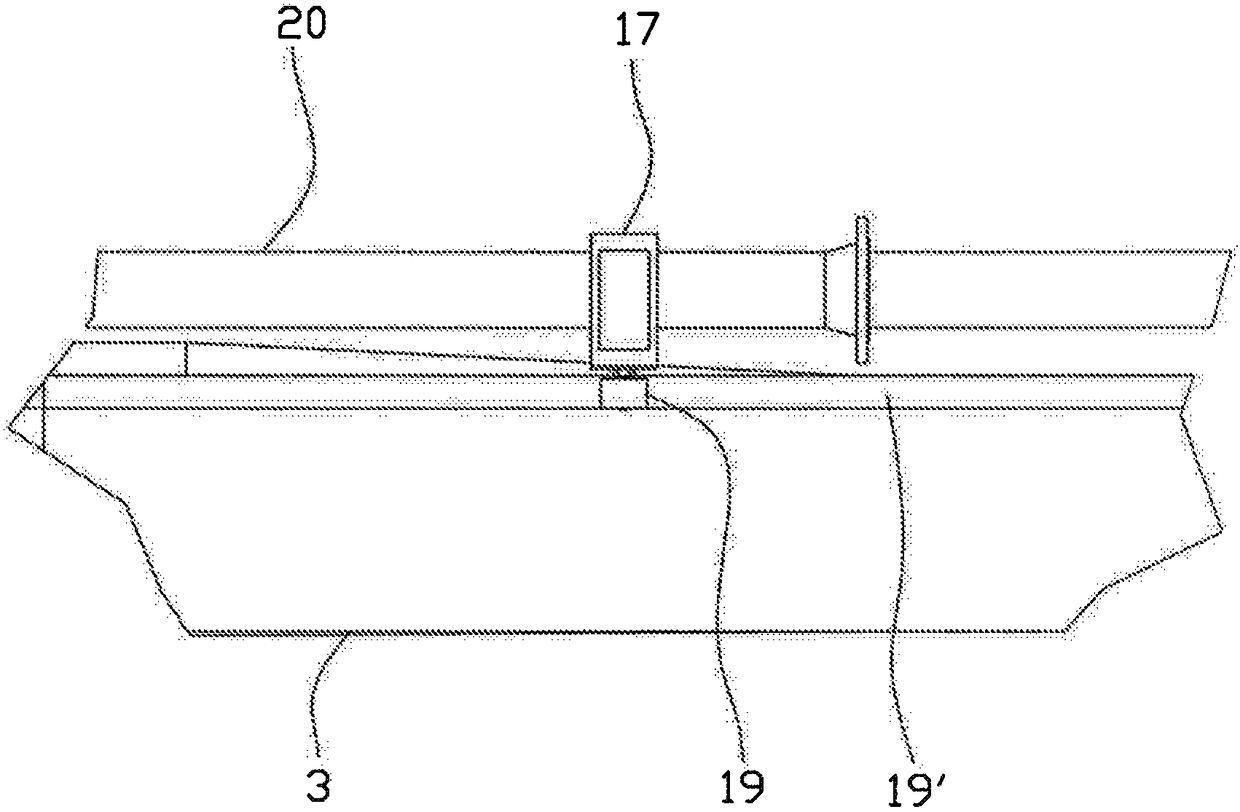

[0066] In the figures, reference numeral 1 designates a device according to the invention. The plant 1 comprises a conveyor belt or carrier 3 for bringing material M from a receiving section 5 to a discharge section 7 .

[0067] The carrier 3 is provided with compressible or squeezeable sorption means 9 adapted to absorb and / or absorb liquid from the material M as it is carried between the receiving part 5 and the discharge part 7 .

[0068] exist figure 1 , the material M is supplied to the receptacle 5 of the plant 1 by means of two screening devices S shown here for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com