Accumulator

A technology for accumulators and pressure vessels, applied in accumulator devices, actuator accumulators, fluid pressure actuating devices, etc., can solve problems such as damage, plastic deformation of metal bellows, collisions, etc., and achieve reliable sealing , suppress collision, suppress tilt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

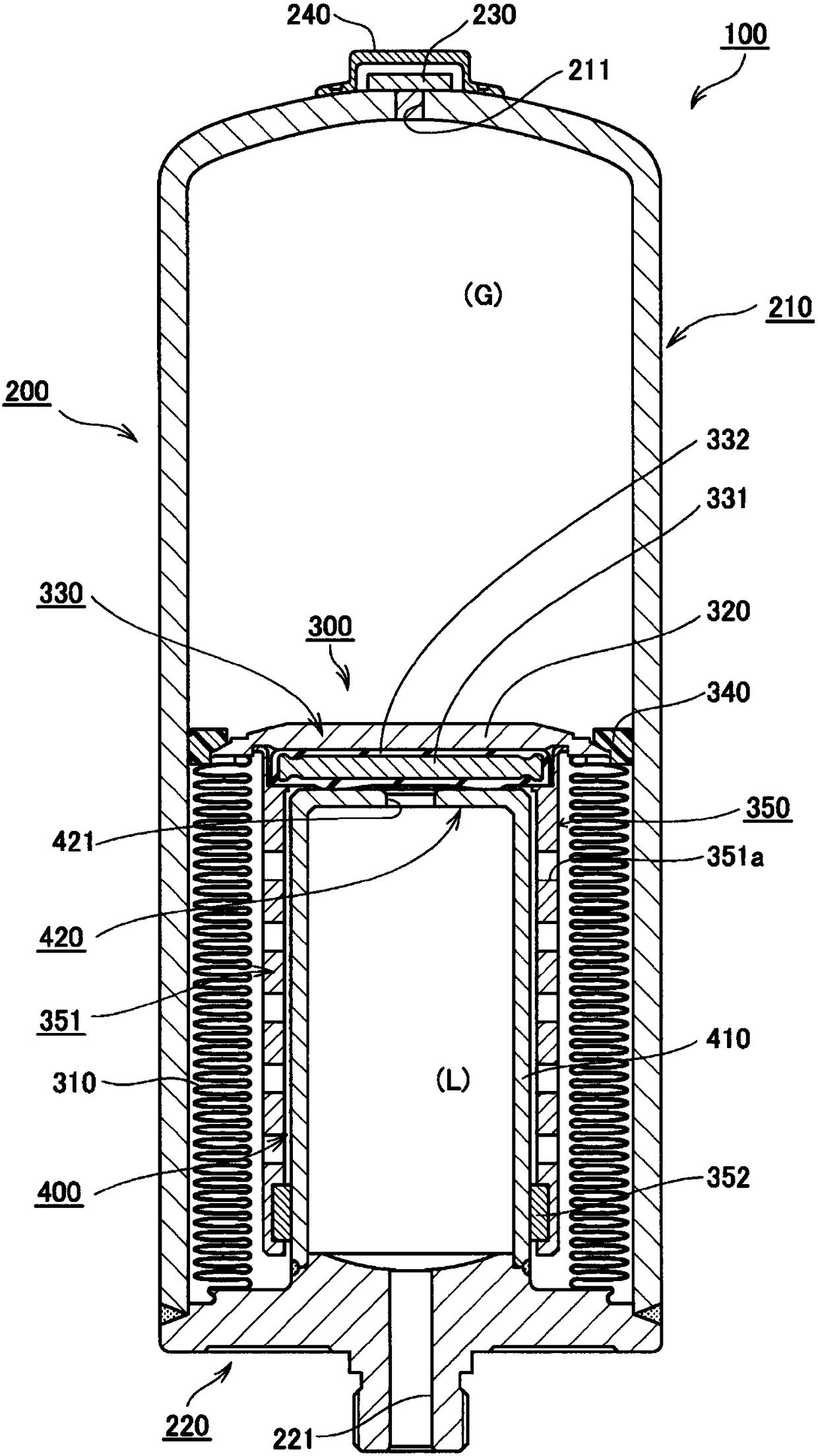

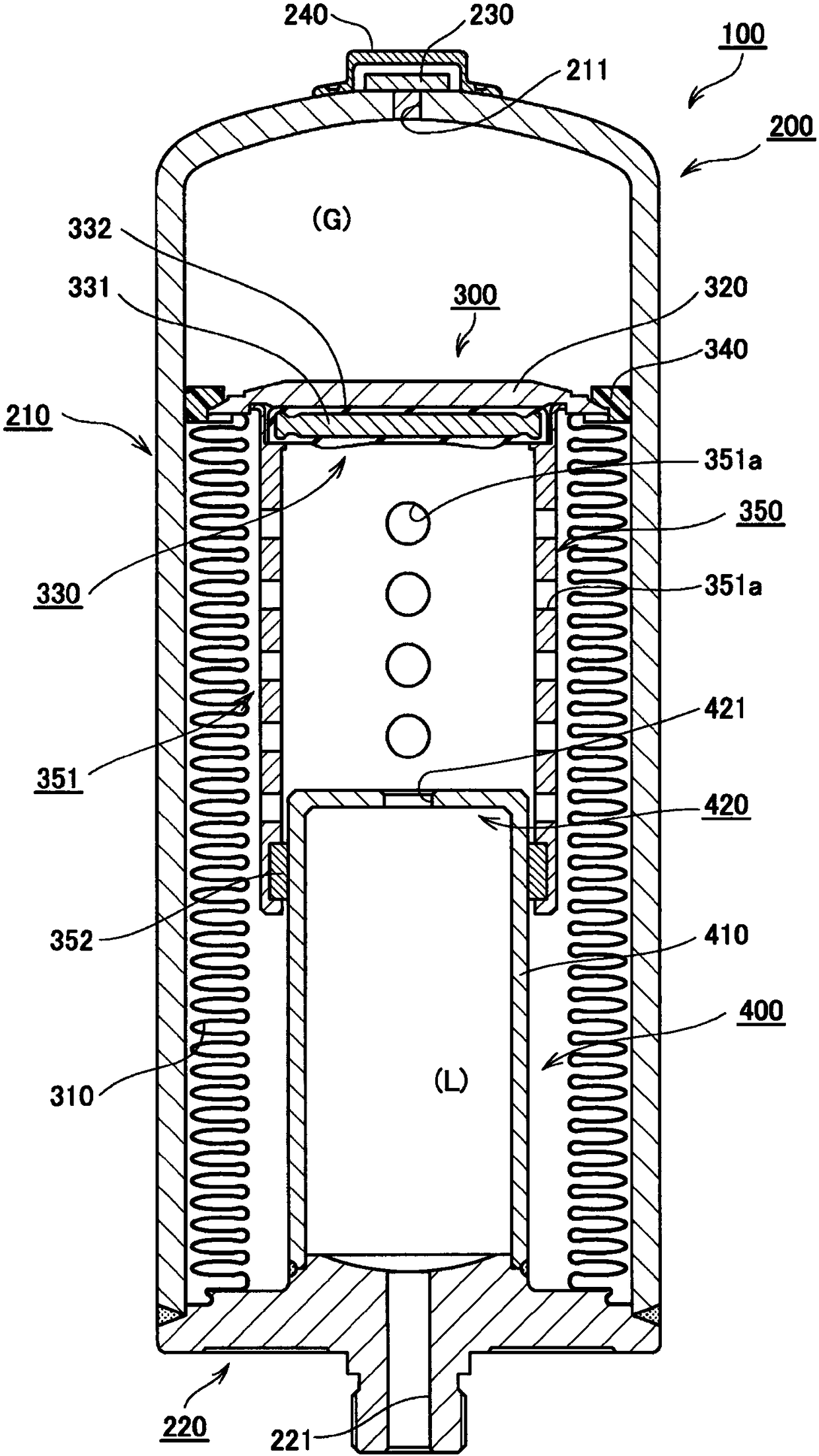

[0050] refer to figure 1 and figure 2 The accumulator according to Embodiment 1 of the present invention will be described. figure 1 and figure 2 It is a schematic cross-sectional view of the accumulator involved in Embodiment 1 of the present invention, figure 1 Indicates the shortened state of the metal bellows, figure 2 Indicates the stretched state of the metal bellows.

[0051]

[0052] The overall structure of the accumulator according to Embodiment 1 of the present invention will be described. The accumulator 100 according to this embodiment can be used to release a large amount of energy in a short time, to moderate pressure fluctuations, and the like. As a more specific example, it can be used, for example, to moderate pulsation in piping through which oil flows in an automobile. In addition, the accumulator 100 according to the present embodiment has a rotationally symmetrical shape with respect to the central axis except for some members (structural me...

Embodiment 2

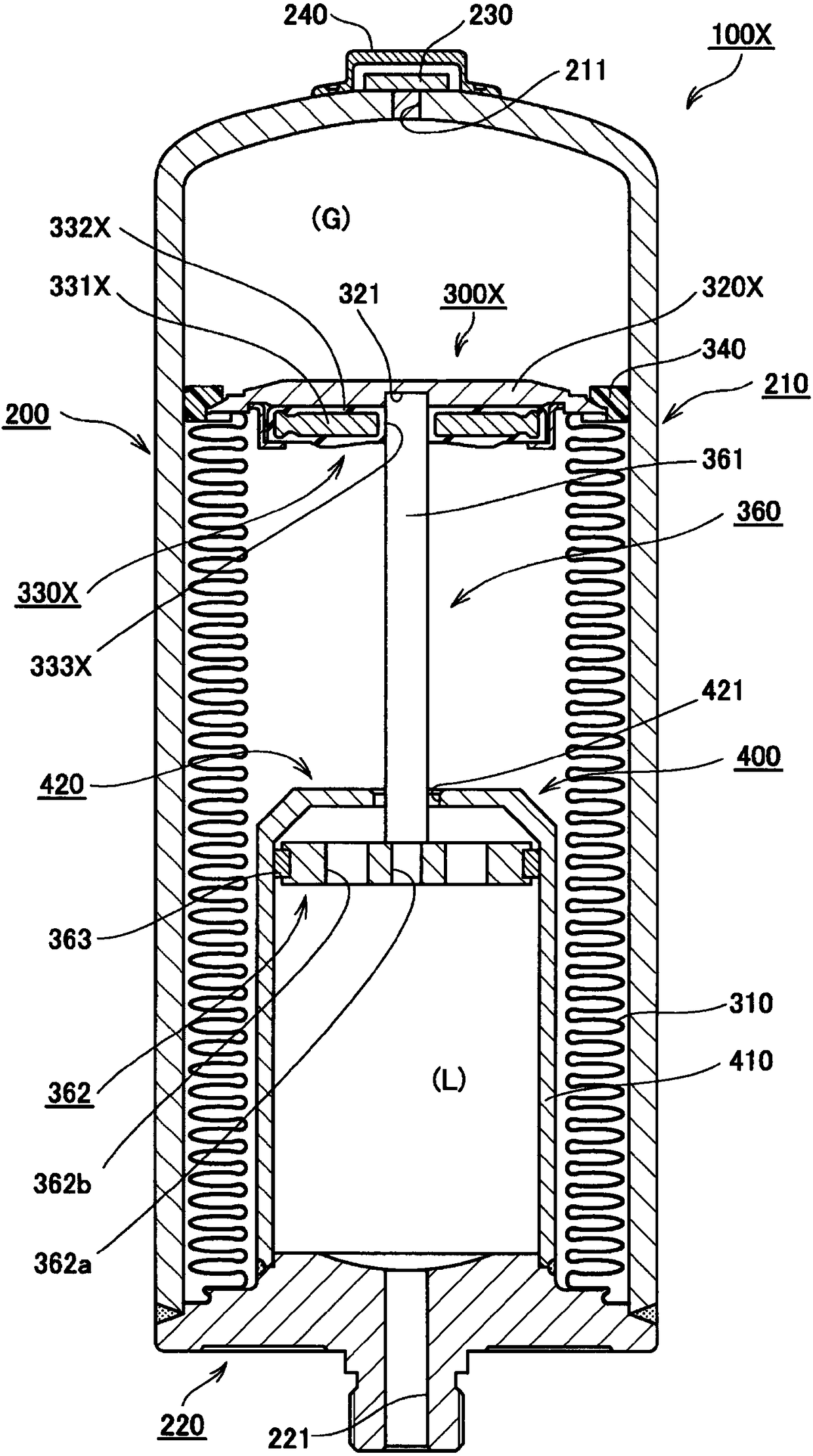

[0071] image 3 Example 2 of the present invention is shown. In the present embodiment, a structure in which the structure related to the slide unit is different from that of the first embodiment is shown. Since other structures and functions are the same as those in Embodiment 1, the same symbols are attached to the same structural parts and their descriptions are appropriately omitted. image 3 It is a schematic cross-sectional view of the accumulator according to Example 2 of the present invention, and shows a state where the metal bellows is stretched.

[0072] In the accumulator 100X of this embodiment, the structure of the sliding unit 360 is different from that of the first embodiment, and the partial shapes of the pressure vessel 200 and the bracket 400 are different, but the basic structure and function are the same as those of the first embodiment.

[0073] As in the case of the first embodiment, the partition unit 300X according to the present embodiment also incl...

Embodiment 3

[0081] Figure 4 Example 3 of the present invention is shown. This embodiment shows a structure in which the structure of the sliding unit is different from that of the first embodiment. Since other structures and functions are the same as those in Embodiment 1, the same symbols are attached to the same structural parts and their descriptions are appropriately omitted. In addition, the same structural parts as in the second embodiment are given the same symbols and their descriptions are appropriately omitted. Figure 4 It is a schematic cross-sectional view of an accumulator according to Example 3 of the present invention, and shows a state where the metal bellows is stretched.

[0082] In the accumulator 100Y according to this embodiment, the structure of the sliding unit is different from that of the first embodiment, and the partial shapes of the pressure vessel 200 and the bracket 400 are different, but the basic structure and function are the same as those of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com