Method for measuring the filling level of a filling material in a container

A filling material and material level technology, which is applied in measuring devices, radio wave measuring systems, liquid/fluid solid measuring, etc., can solve the problems of time-expanded envelope curve evaluation, complex circuit system, etc., and achieve omission of digital data processing, Effect of Reducing Power Consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

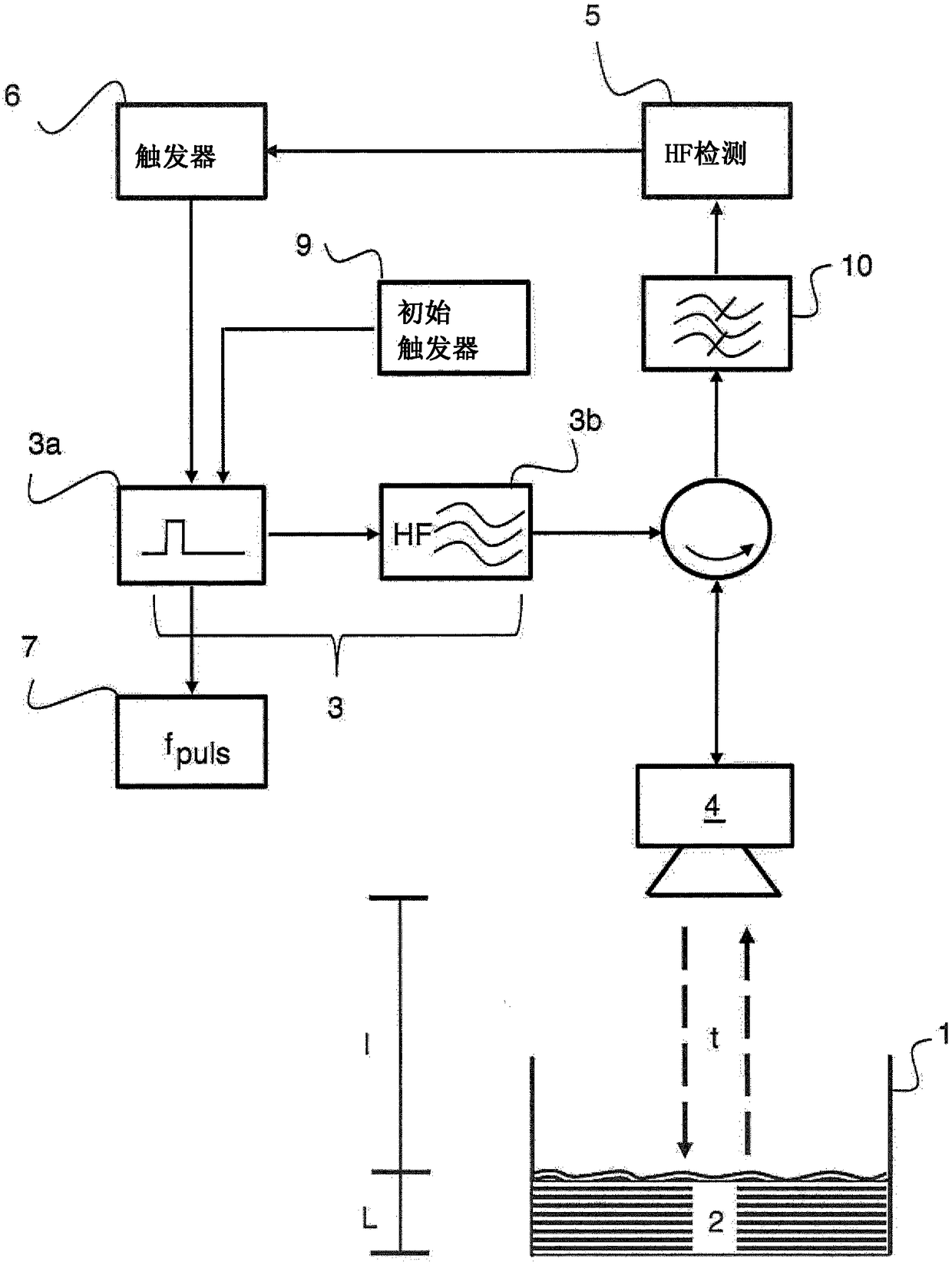

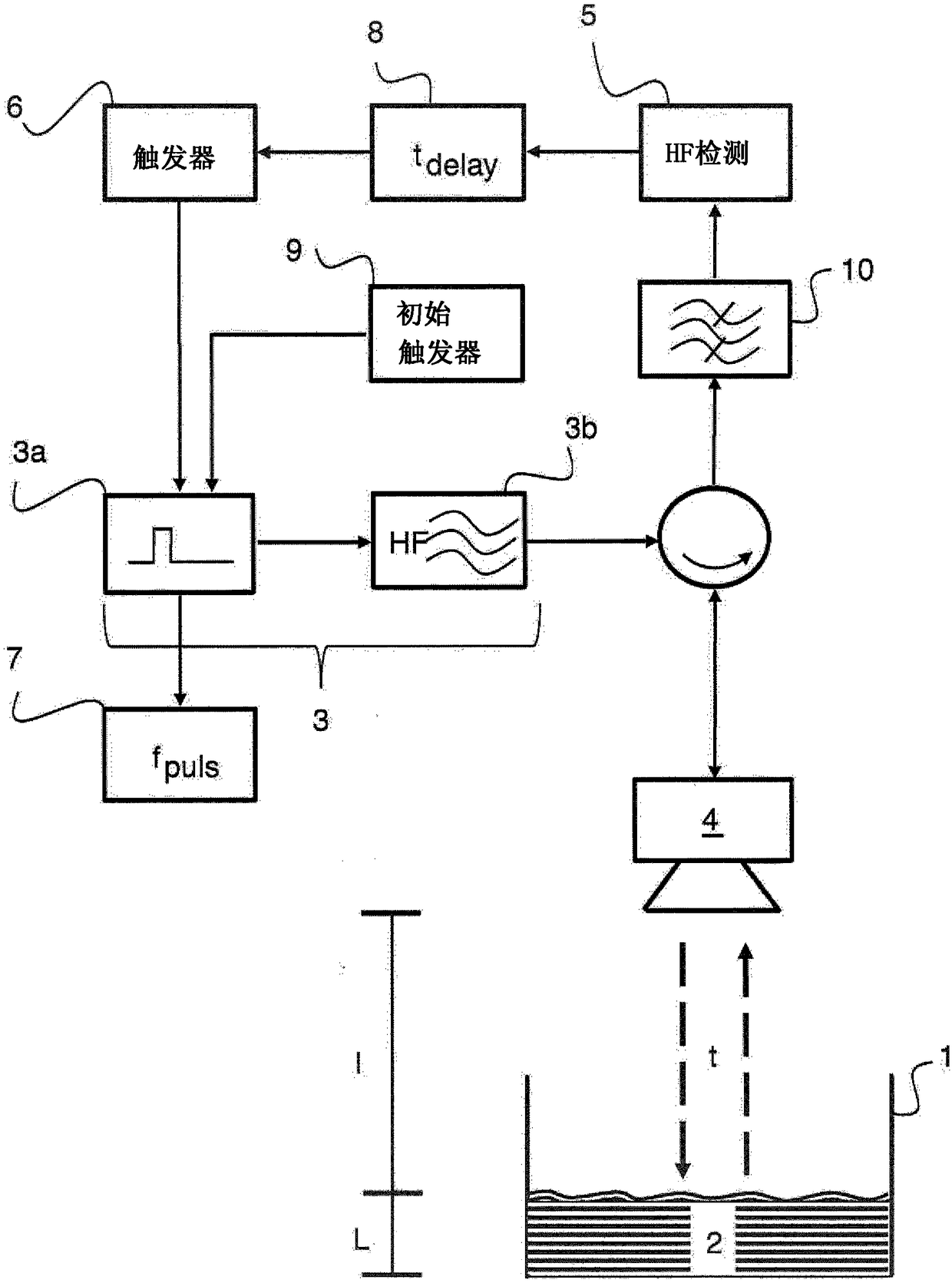

[0050] Based on the block diagram showing the level measuring device of the present invention figure 1 , the operation of the method of the invention for measuring the level L of the filling substance 2 located in the container 1 will be explained below.

[0051] Position the level measuring device on the figure 1 At a predefined height I above the bottom of the container 1 in the illustration of . Via the level measuring device via the antenna unit 4 according to the repetition frequency f puls Microwave pulses are sent towards the filling substance 2 . Microwave pulses are excited via the pulse generation unit 3 and introduced via a duplexer into the antenna unit 4 in which they are radiated towards the filling substance 2 .

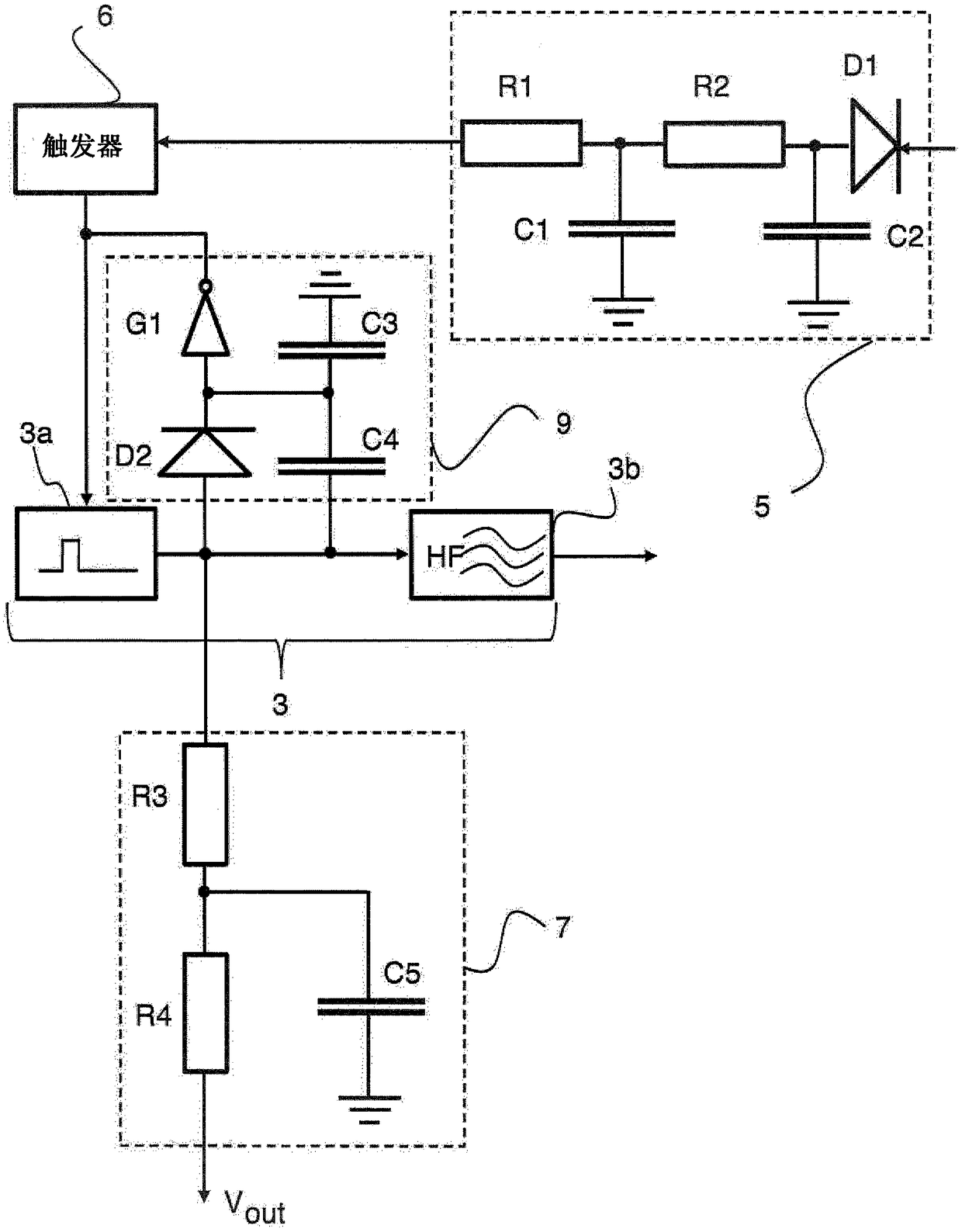

[0052] As is known from the prior art of pulse radars, the pulse generating unit 3 consists of two parts: a pulse generator 3a and a high-frequency generator 3b, which preferably has a low quality factor. In this case, the duration of the microwave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com