Clutch control method and device, and vehicle

A control method and technology of a control device, applied in the direction of the control device, etc., can solve the problems of no power output of the vehicle, easy to cause danger, etc., and achieve the effect of avoiding the problem of slippage, avoiding overheating and wear, and reducing the frequency of wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

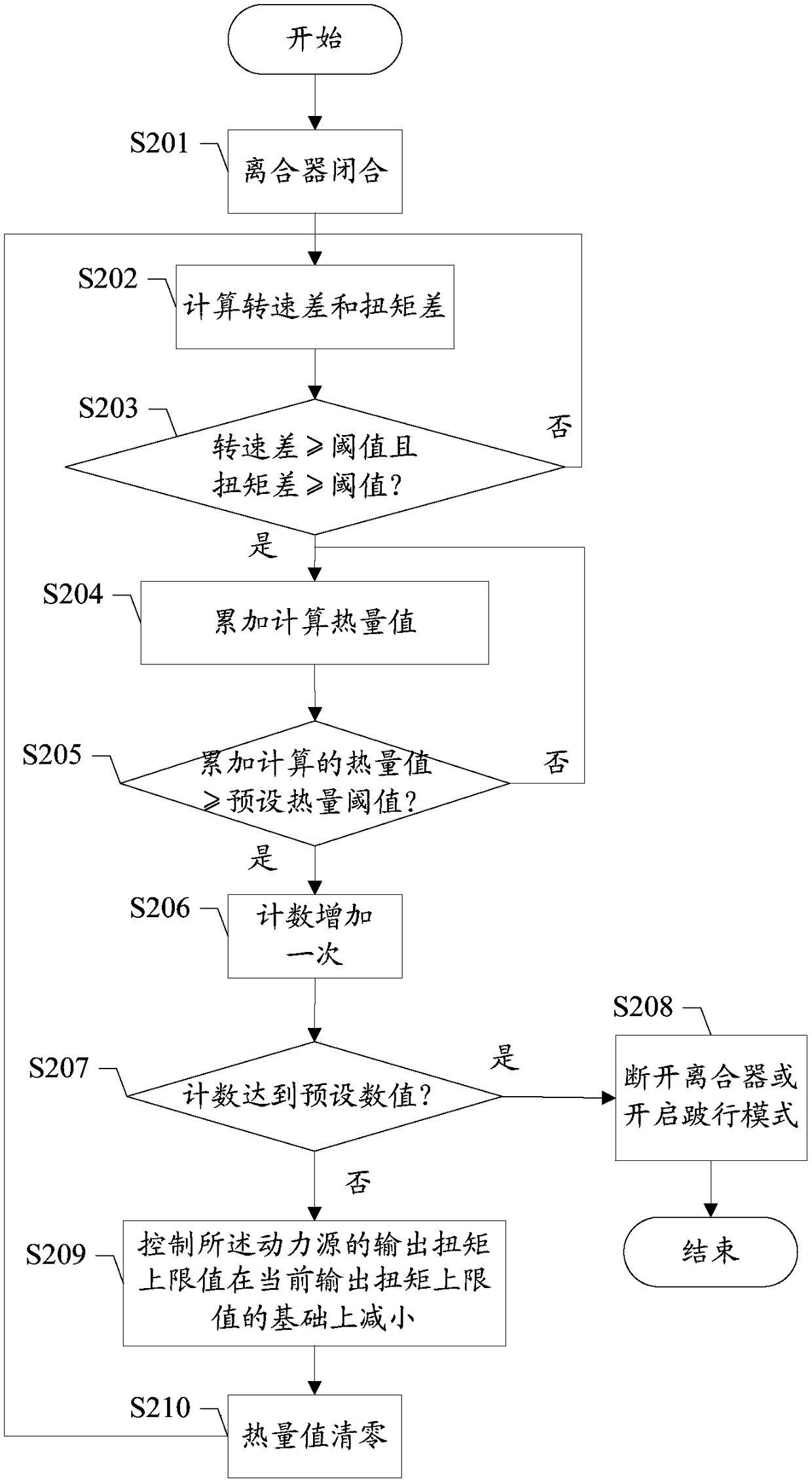

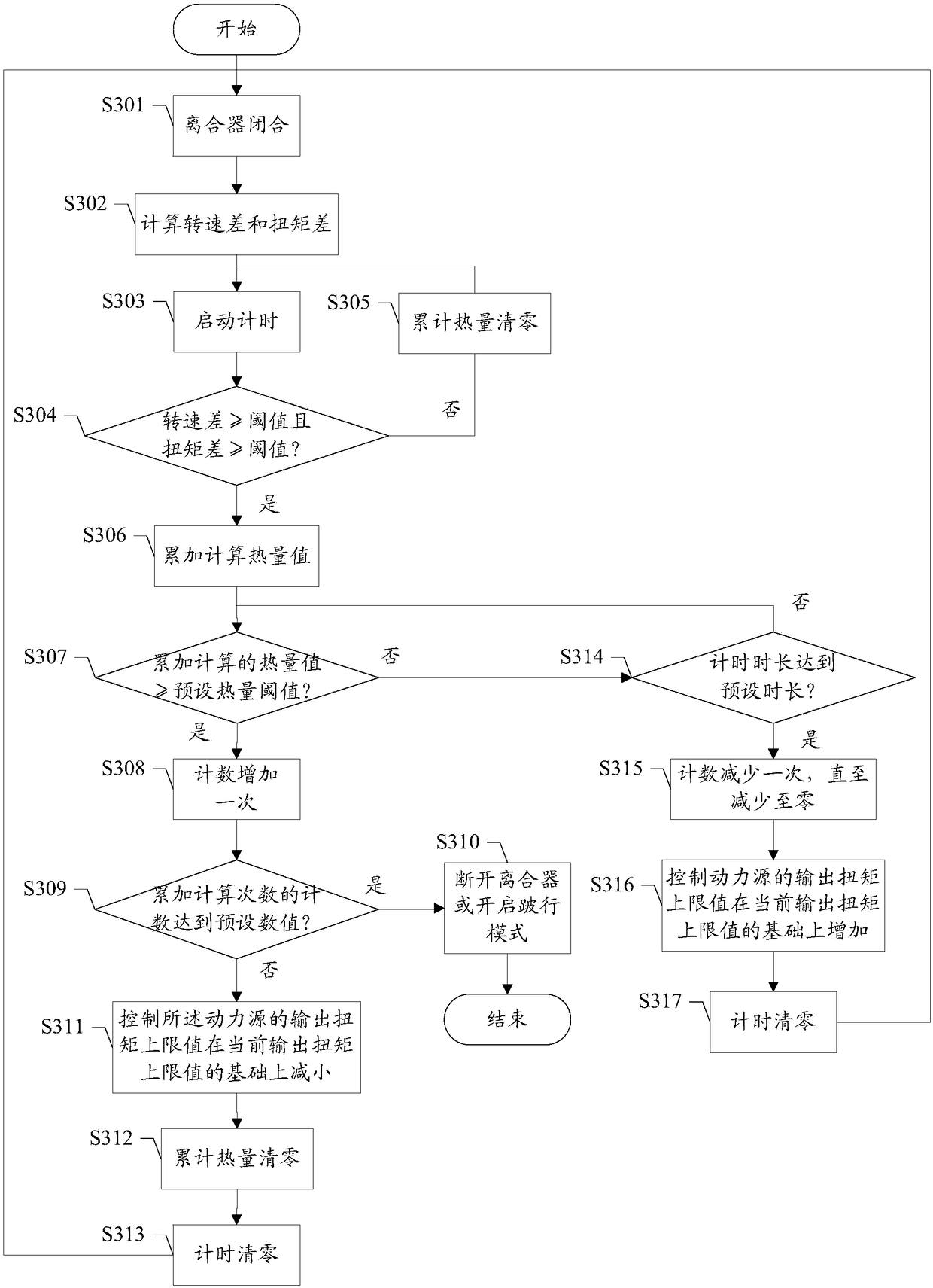

[0032] As mentioned above, when the torque difference and speed difference between the power source of the car and the clutch are large, the clutch will slip. Once the clutch plate slips, it is easy to generate and accumulate heat in the clutch, which will lead to clutch failure wear and tear. This problem is exacerbated by the faster torque response in automatic clutches.

[0033] However, in the prior art, when the heat accumulated on the clutch exceeds the heat threshold, the technical solution adopted is usually to directly disconnect the clutch, thereby cutting off the torque output from the power source to the transmission, which will cause the vehicle to suddenly have no power output. In unsafe road sections, it is easy to cause danger.

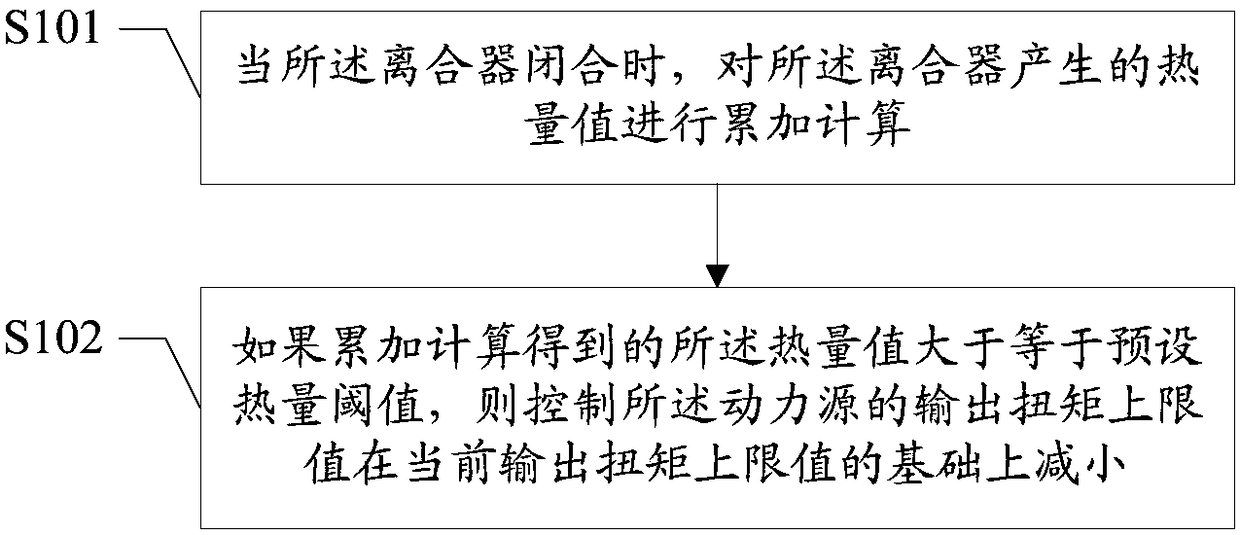

[0034] The inventors of the present invention have found through research that the key to the above problems is that when the heat accumulated on the clutch exceeds the heat threshold and slipping occurs, the torque transmission capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com