Honeycomb plate feeding device

A technology of honeycomb panels and guide rails, which is applied in the field of honeycomb panel feeding devices, and can solve problems such as inability to install honeycomb panels, low efficiency, and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

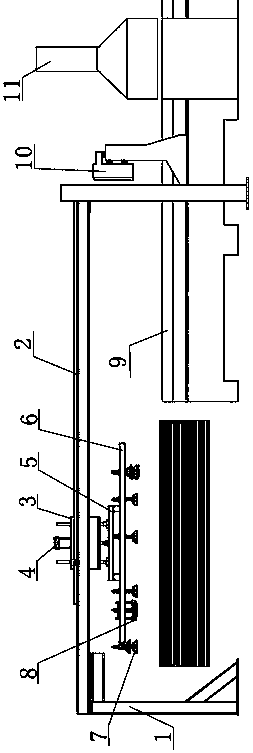

[0009] Such as figure 1 The honeycomb sheet material device shown includes a bracket 1, a guide rail 2, a moving block 3 is installed on the guide rail 2, a lifting column 4 is installed on the moving block 3, a fixing frame 5 is connected to the bottom of the lifting column 4, and the bottom of the fixing frame 5 A suction cup holder 6 is installed. The size of the suction cup holder 6 corresponds to the size of the honeycomb panel component being transported. The suction cup holder 6 is equipped with a rubber disk 7 through a connecting rod and a spring, and the suction cup holder 6 is also installed with a connecting rod and spring. Pressure sensor 8; under one end of the guide rail 2, there is a roller conveyor 9, and the roller conveyor 9 is sequentially installed with a proximity sensor 10, a vacuum cleaner 11, a pressure sensor 8, a lifting column 4, a guide rail 2, a proximity sensor 10 and a vacuum cleaner 11 Connect with the controller electric control.

[0010] When i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com