Modified flame-retardant antibacterial PU synthetic leather production technology and manufacturing facility

A production process and technology for synthetic leather, applied in the field of synthetic leather, can solve the problems of poor flame retardant and antibacterial effect of synthetic leather, and achieve the effects of enhancing stability and durability, reducing pollution, and facilitating popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

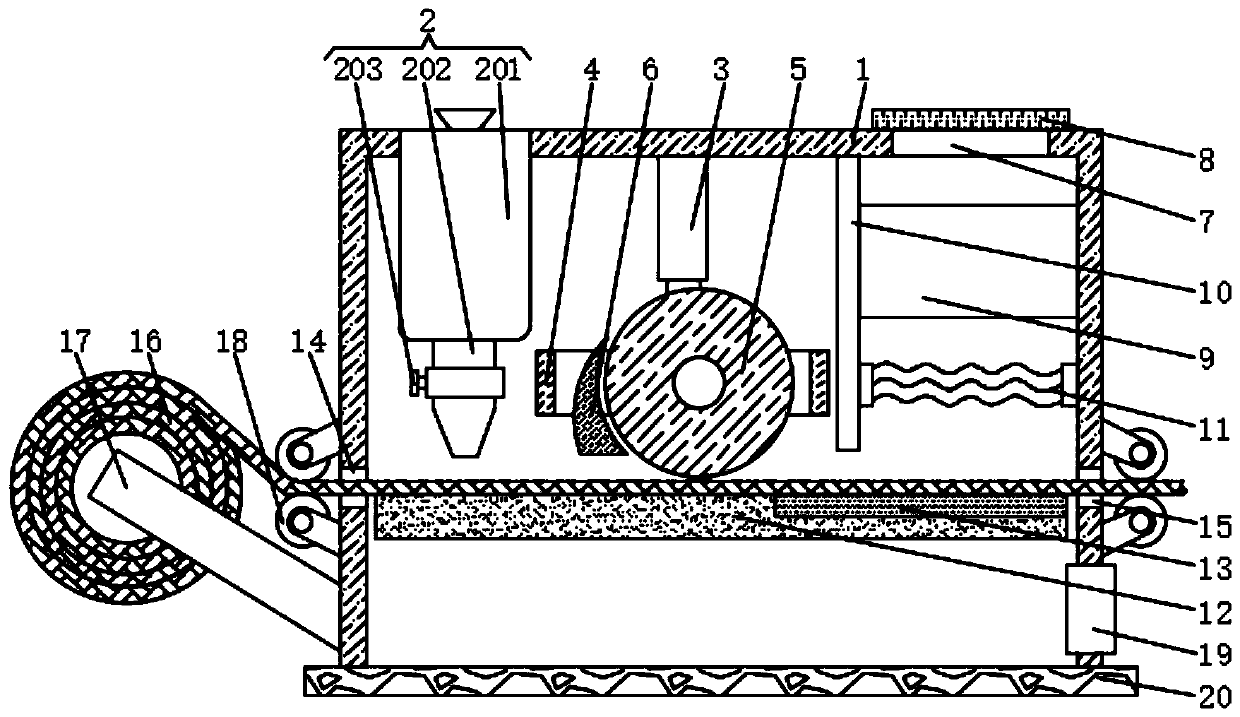

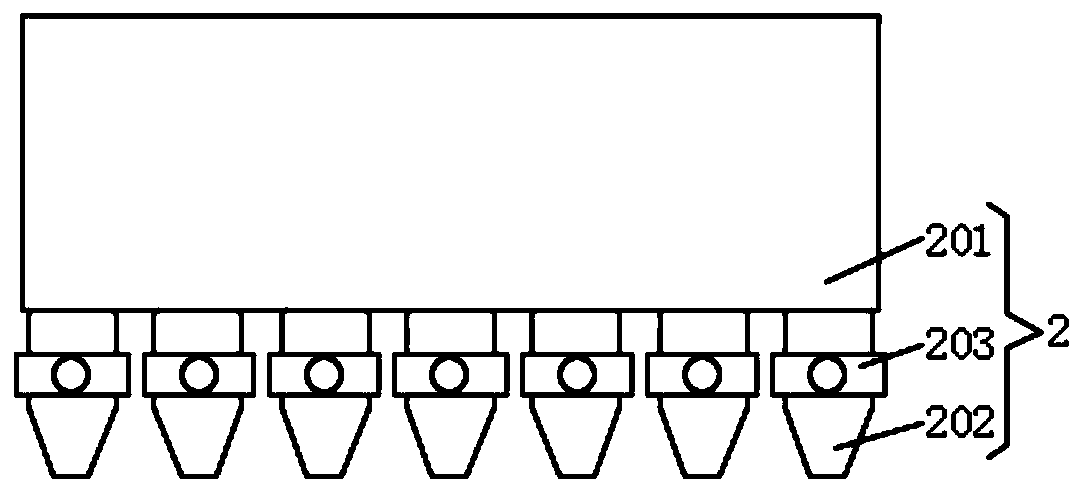

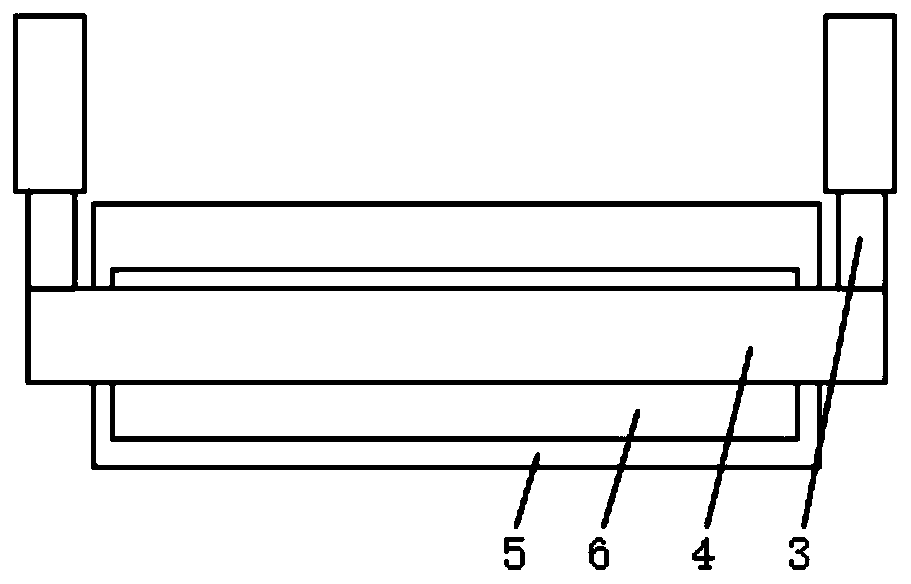

[0046] Such as Figure 1-3 As shown, the present invention provides a kind of technical scheme: a kind of production process of modified flame-retardant antibacterial PU synthetic leather, comprises the following steps:

[0047] S1. Acid treatment and alkali treatment: immerse the polyester base fabric in the acid treatment solution at a temperature of 70-80°C for 15-20 minutes, then dry it in vacuum at 90-95°C, and then immerse the treated polyester base fabric in In the alkali treatment solution, the temperature is 75-85°C, and the treatment time is 30-40 minutes. After treatment, it is washed with water and dried to constant weight.

[0048] S2. Modified flame retardant: immerse the polyester base fabric treated in S1 in the flame retardant solution at a temperature of 25-35°C, and a treatment time of 80-100min. After treatment, dry it, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com