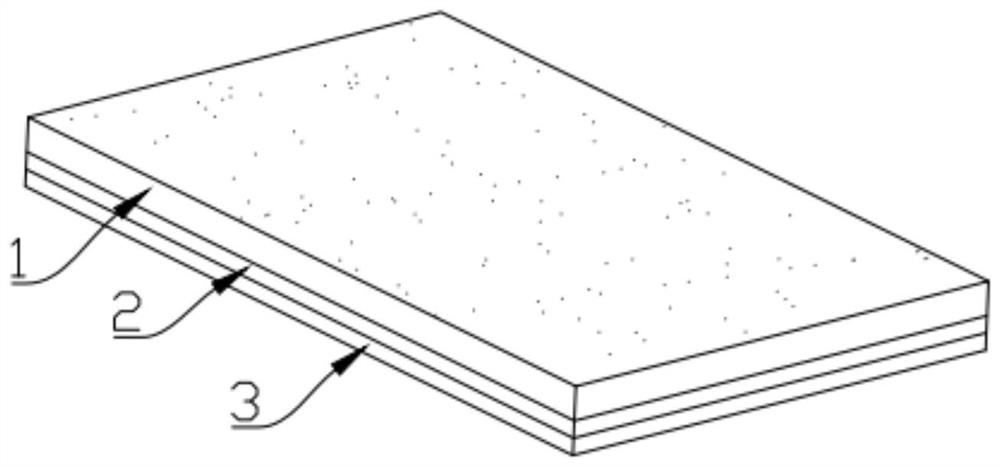

Flame-retardant acrylic plate

A technology of flame retardant acrylic sheet and flame retardant, which is used in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of inability to meet the requirements of design sense, single color, and weak decorative effect. , to achieve the effect of good flatness, good adaptability and strong decorative sense.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

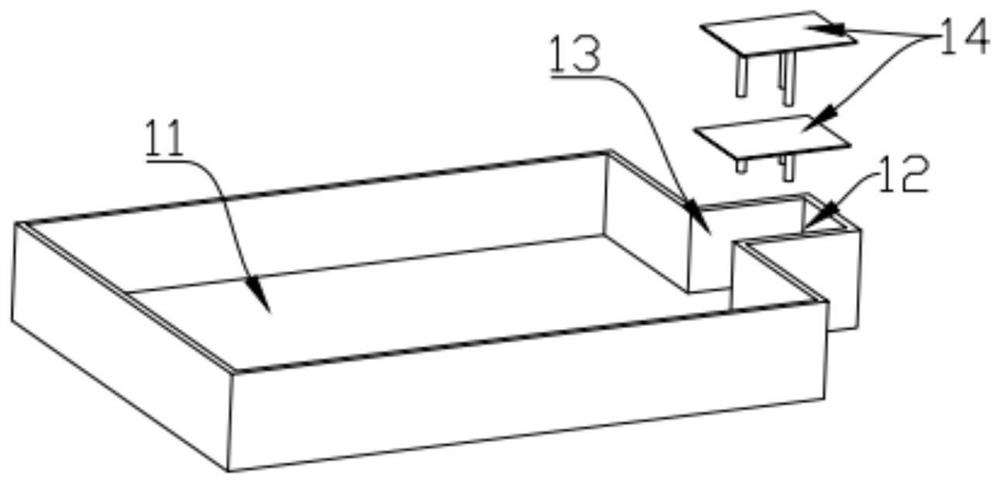

[0036] Follow the steps below to form a flame-retardant acrylic sheet:

[0037] The first step is to prepare 100 parts of silicone resin, 50 parts of methyl methacrylate, 10 parts of urea-formaldehyde resin and 10 parts of ethylene glycol acrylate. First, dissolve the silicone resin in methyl Stir in methyl acrylate, then heat up to 40-50°C, then add urea-formaldehyde resin and ethylene glycol acrylate into the reaction kettle, stir evenly, prepare organic glass solution, and set aside;

[0038] The second step is to prepare 10 parts of silicon carbide fiber, 10 parts of zinc borate, 10 parts of calcium chloride, 1 part of calcium stearate, 1 part of sodium phosphate, copper oxide, zinc silicate and zinc oxide according to 1:1:1 Ratio ingredients: 5 parts of inorganic antibacterial agent, 2 parts of flame retardant in proportion of magnesium hydroxide and aluminum hydroxide according to 1:1 ratio, and the above materials are ground into powder for many times, all sieved until ...

Embodiment 2

[0042] Follow the steps below to form a flame-retardant acrylic sheet:

[0043] The first step is to prepare 200 parts of silicone resin, 20 parts of methyl methacrylate, 30 parts of urea-formaldehyde resin and 20 parts of ethylene glycol acrylate. First, dissolve the silicone resin in methyl methacrylate in the reaction kettle at room temperature, stir, then raise the temperature to 40-50°C, then add urea-formaldehyde resin and ethylene glycol acrylate into the reaction kettle, stir Evenly, prepare the plexiglass solution and set aside;

[0044] The second step is to prepare 30 parts of silicon carbide fiber, 30 parts of zinc borate, 20 parts of calcium chloride, 10 parts of calcium stearate, 10 parts of sodium phosphate, copper oxide, zinc silicate and zinc oxide according to 1:1:1 Ratio ingredients: 15 parts of inorganic antibacterial agent, magnesium hydroxide and aluminum hydroxide according to 1:1 proportioning ratio of 10 parts of flame retardant, and the above materia...

Embodiment 3

[0048] Follow the steps below to form a flame-retardant acrylic sheet:

[0049] In the first step, prepare 150 parts of silicone resin, 100 parts of methyl methacrylate, 20 parts of urea-formaldehyde resin and 15 parts of ethylene glycol acrylic acid. First, dissolve the silicone resin in methyl methacrylate in the reaction kettle at room temperature, stir, then raise the temperature to 40-50°C, then add urea-formaldehyde resin and ethylene glycol acrylate into the reaction kettle, stir Evenly, prepare the plexiglass solution and set aside;

[0050] The second step is to prepare 20 parts of silicon carbide fiber, 20 parts of zinc borate, 15 parts of calcium chloride, 5 parts of calcium stearate, 5 parts of sodium phosphate, copper oxide, zinc silicate and zinc oxide according to the ratio of 1:1:1 Ratio ingredients: 10 parts of inorganic antibacterial agent, 5 parts of magnesium hydroxide and aluminum hydroxide according to the ratio of 1:1, and 5 parts of flame retardant, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com