A laser glass ion exchange enhancement method

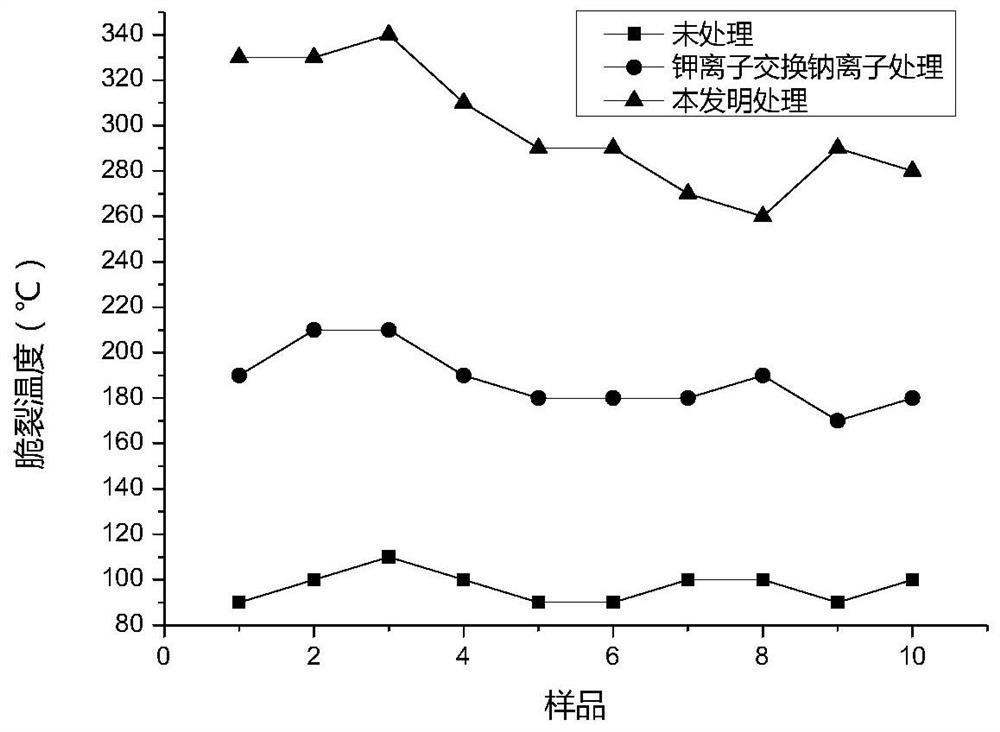

A laser glass and ion exchange technology, applied in the field of laser glass, can solve the problems of reduced chemical stability of glass, easy to be corroded, and the surface cannot be effectively repaired, etc., to achieve enhanced chemical stability, long stress relaxation time, and improved surface chemical stability. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present embodiment adopts phosphate laser glass, and the adopted mixed molten salt 1, mixed molten salt 2 and mixed acid have the following compositions:

[0041] Mix molten salt 1:

[0042] Composition wt%

[0043] RbNO3 10%

[0044] CsNO3 90%

[0045] Mixed molten salt 2:

[0046] Composition wt%

[0047] LiNO3 15%

[0048] NaNO3 85%

[0049] Mixed acid:

[0050]

[0051] This embodiment includes the following steps:

[0052] S11: The sample is washed with deionized water and dried.

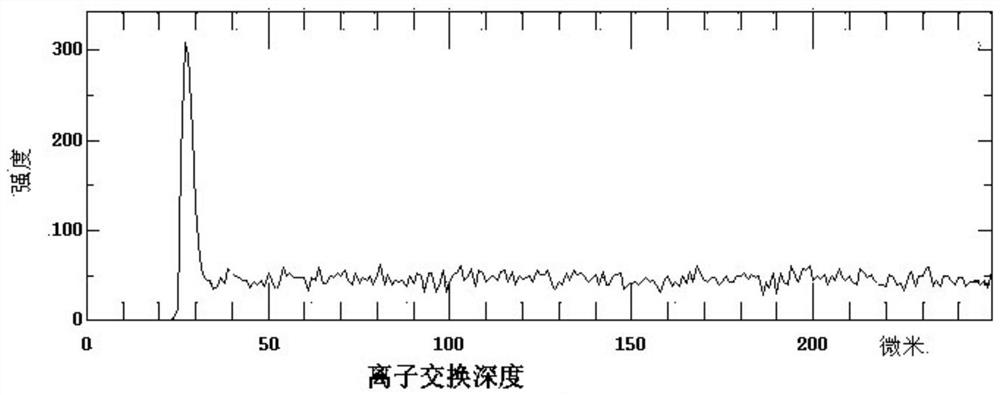

[0053] S12: Put the mixed molten salt 1 prepared in proportion into the ion exchange vessel, put it in a muffle furnace to heat up to 450°C and stabilize, and then preheat the sample processed in step S11 to 340°C and transfer it to the ion exchange vessel.

[0054] S13: in a muffle furnace at 450° C. for 8 hours, taking out and annealing to room temperature in an annealing furnace.

[0055] S21: Wash the sample processed in step S13 with deionized water and dry it.

[...

Embodiment 2

[0062] The present embodiment adopts phosphate laser glass, and the adopted mixed molten salt 1, mixed molten salt 2 and mixed acid have the following compositions:

[0063] Mix molten salt 1:

[0064] Composition wt%

[0065] RbNO3 20%

[0066] CsNO3 80%

[0067] Mixed molten salt 2:

[0068] Composition wt%

[0069] LiNO3 11%

[0070] NaNO3 89%

[0071] Mixed acid:

[0072]

[0073] This embodiment includes the following steps:

[0074] S11: The sample is washed with deionized water and dried.

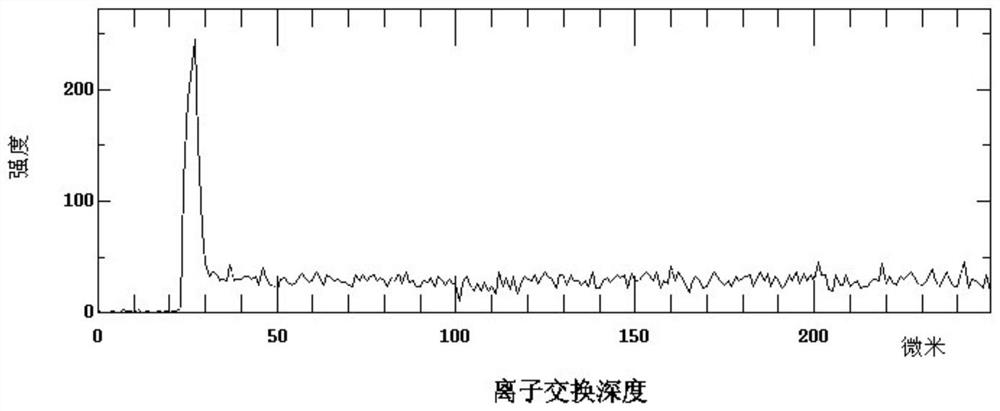

[0075] S12: Put the mixed molten salt 1 prepared in proportion into the ion exchange vessel, put it in a muffle furnace to heat up to 430°C and stabilize, and then preheat the sample processed in step S11 to 340°C and transfer it to the ion exchange vessel.

[0076] S13: In a muffle furnace, the temperature is kept at 430° C. for 10 hours, then taken out and annealed to room temperature in an annealing furnace.

[0077] S21: Wash the sample processed in step S13 with dei...

Embodiment 3

[0084] The present embodiment adopts phosphate laser glass, and the adopted mixed molten salt 1, mixed molten salt 2 and mixed acid have the following compositions:

[0085] Mix molten salt 1:

[0086] Composition wt%

[0087] RbNO3 30%

[0088] CsNO3 70%

[0089] Mixed molten salt 2:

[0090] Composition wt%

[0091] LiNO3 8%

[0092] NaNO3 92%

[0093] Mixed acid:

[0094]

[0095] This embodiment includes the following steps:

[0096] S11: The sample is washed with deionized water and dried.

[0097] S12: Put the mixed molten salt 1 prepared in proportion into the ion exchange vessel, put it in a muffle furnace to heat up to 420°C and stabilize, and then preheat the sample processed in step S11 to 300°C and transfer it to the ion exchange vessel.

[0098] S13: After keeping in a muffle furnace at 420° C. for 13 hours, take out and anneal to room temperature in an annealing furnace.

[0099] S21: Wash the sample processed in step S13 with deionized water and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com