Fabricated open caisson wall cutting edge structure

A prefabricated shaft wall technology, which is applied in infrastructure engineering, caissons, buildings, etc., can solve the problems of large engineering volume, reduced subsidence coefficient, and small tensile area, and achieves good economy, convenient construction, and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

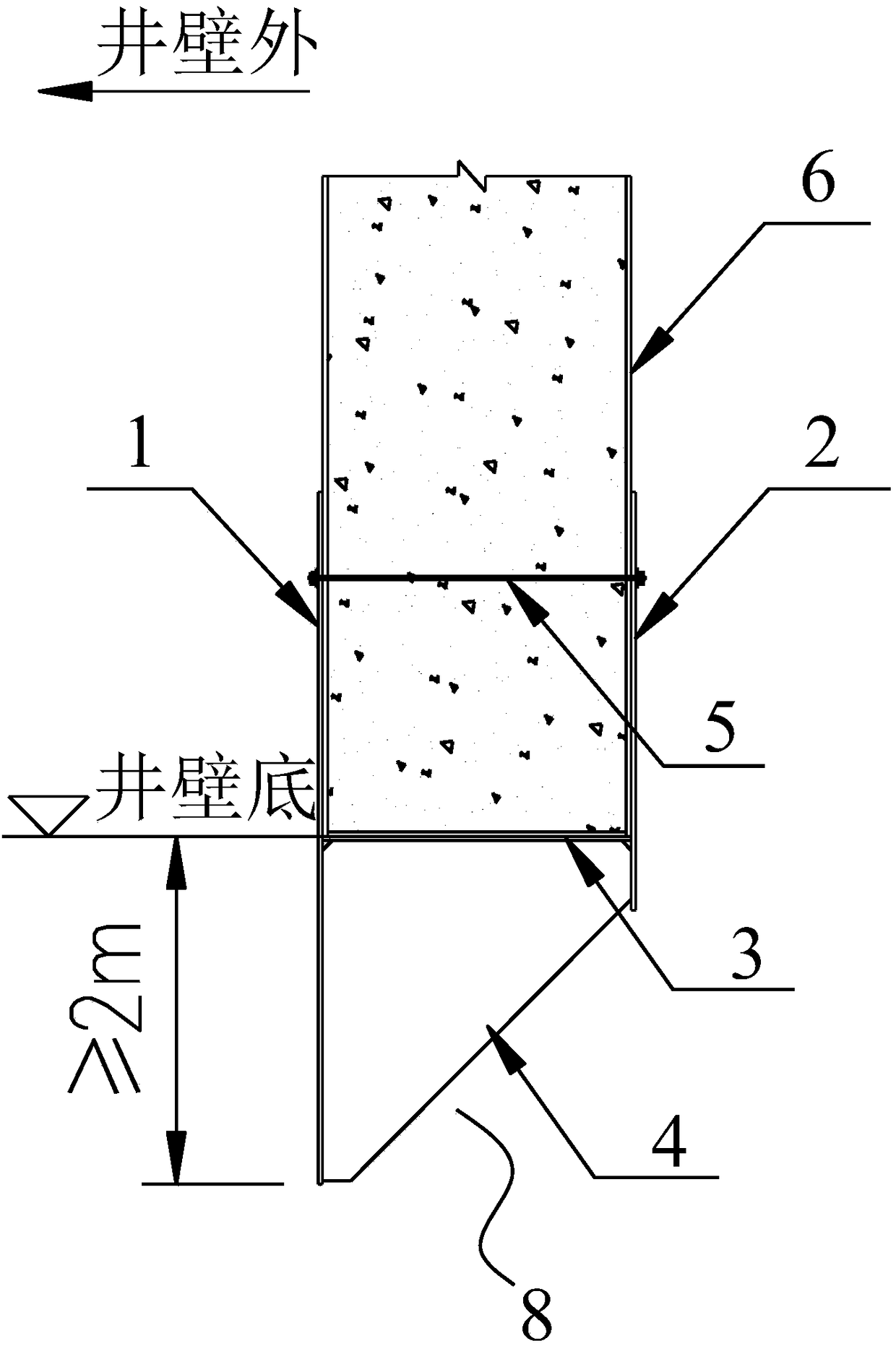

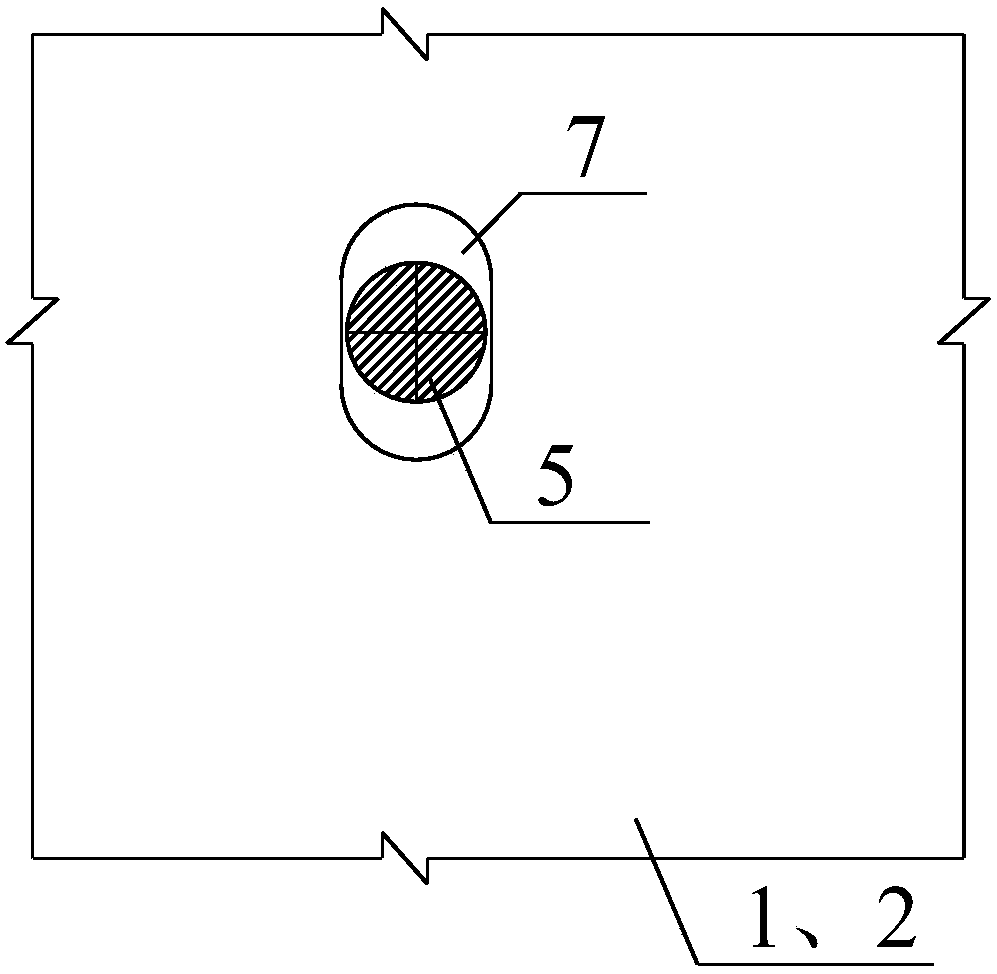

[0021] refer to figure 1 As shown, an assembled caisson wall blade foot structure, the shaft wall blade foot includes an outer vertical plate 1, an inner vertical plate 2, a horizontal plate 3 and a stiffening plate 4 connected as a whole, and the shaft wall blade foot passes through the The pulling screw 5 is assembled on the well wall 6 of the caisson; the outer vertical plate 1 is attached to the outer side of the well wall 6, the inner vertical plate 2 is attached to the inner side of the well wall 6, the horizontal plate 3 is attached to the bottom of the well wall 6, and the outer vertical plate 1 and the inner vertical plate 2 are hinged to the well wall 6 through the pull screw 5 passing through the well wall 6, the outer vertical plate 1 and the inner vertical plate 2 both protrude below the bottom of the well wall 6, and the outer vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com