Mining area handcart weighing system

A technology of weighing system and trolley, applied in signal transmission system, detailed information of weighing equipment, weighing and other directions, can solve the problems of high man-made, time-consuming and labor-intensive, and achieve simple structure, unified management, and reduced configuration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

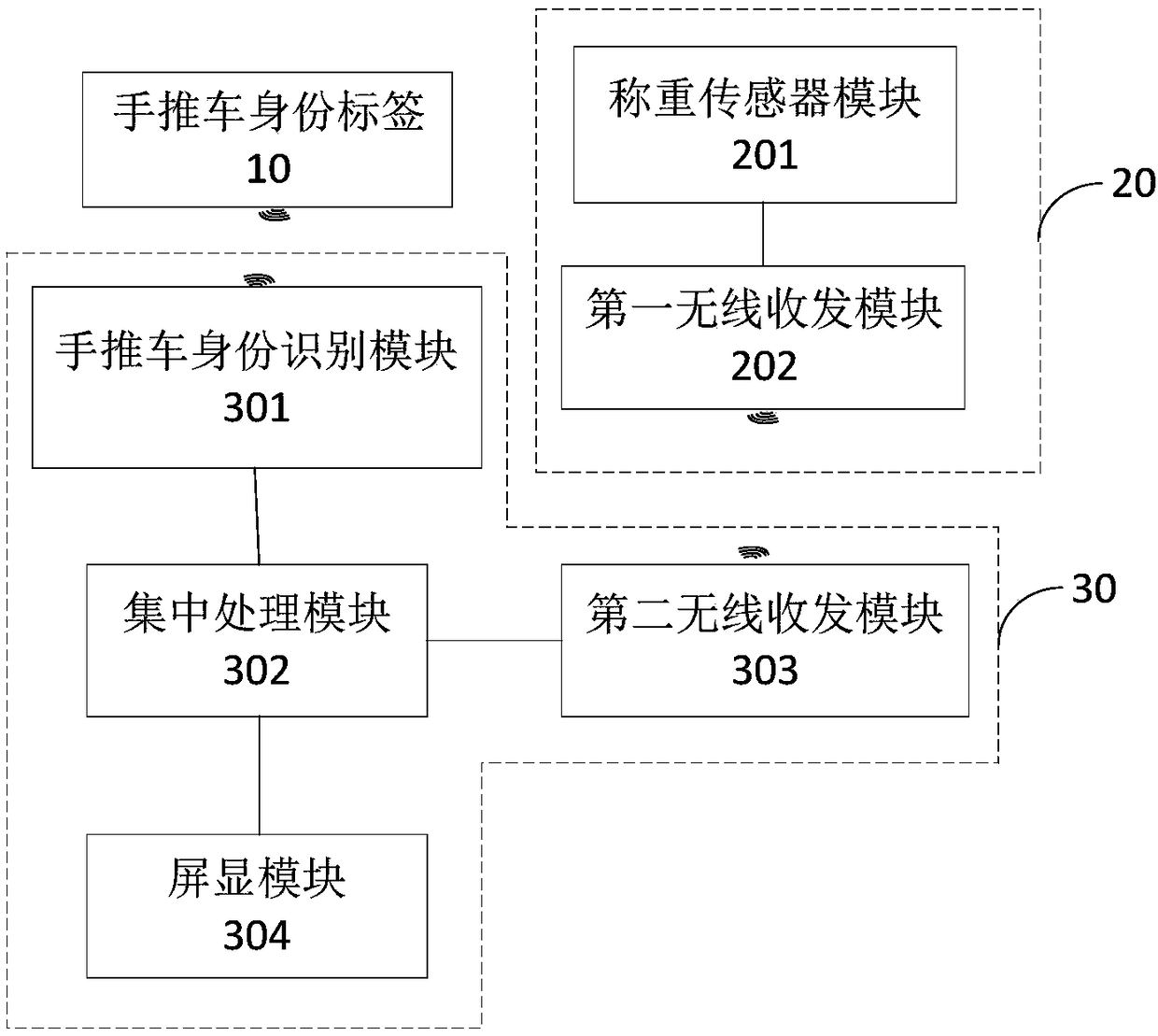

[0015] Such as figure 1 As shown, the trolley weighing system in the mining area includes a trolley identity tag 10, a weighing module 20 and a weight statistics module 30, and the weighing module 20 includes a trolley identification module 301, a centralized processing module 302, a second wireless transceiver module 303 and the screen display module 304, the trolley identity recognition module 301 is used to identify the trolley identity tag 10 under the control of the centralized processing module 302; the sending and receiving; the screen display module 304 is used to display the weight that each trolley weighs; the centralized processing module 302 is used to centrally control each module and handle other matters; the weighing module 20 includes a load cell module 201 and a second A wireless transceiver module 202 ; the load cell module 201 is used to weigh the trolley, and the first wireless transceiver module 202 is used to transmit the weighing result of the load cell ...

Embodiment 2

[0019] A change is made on the basis of the first embodiment, and the trolley identification module 301 is changed into a code system identification module.

[0020] When the system is in use, the identity information of the trolley is obtained by scanning the barcode label of the trolley.

[0021] Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com