Optical imaging system and target simulation system

An optical imaging system and smooth surface technology, applied in the optical field, can solve the problems of low image resolution, low reliability, and small display area, so as to improve resolution, ensure contrast and brightness uniformity, and ensure consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

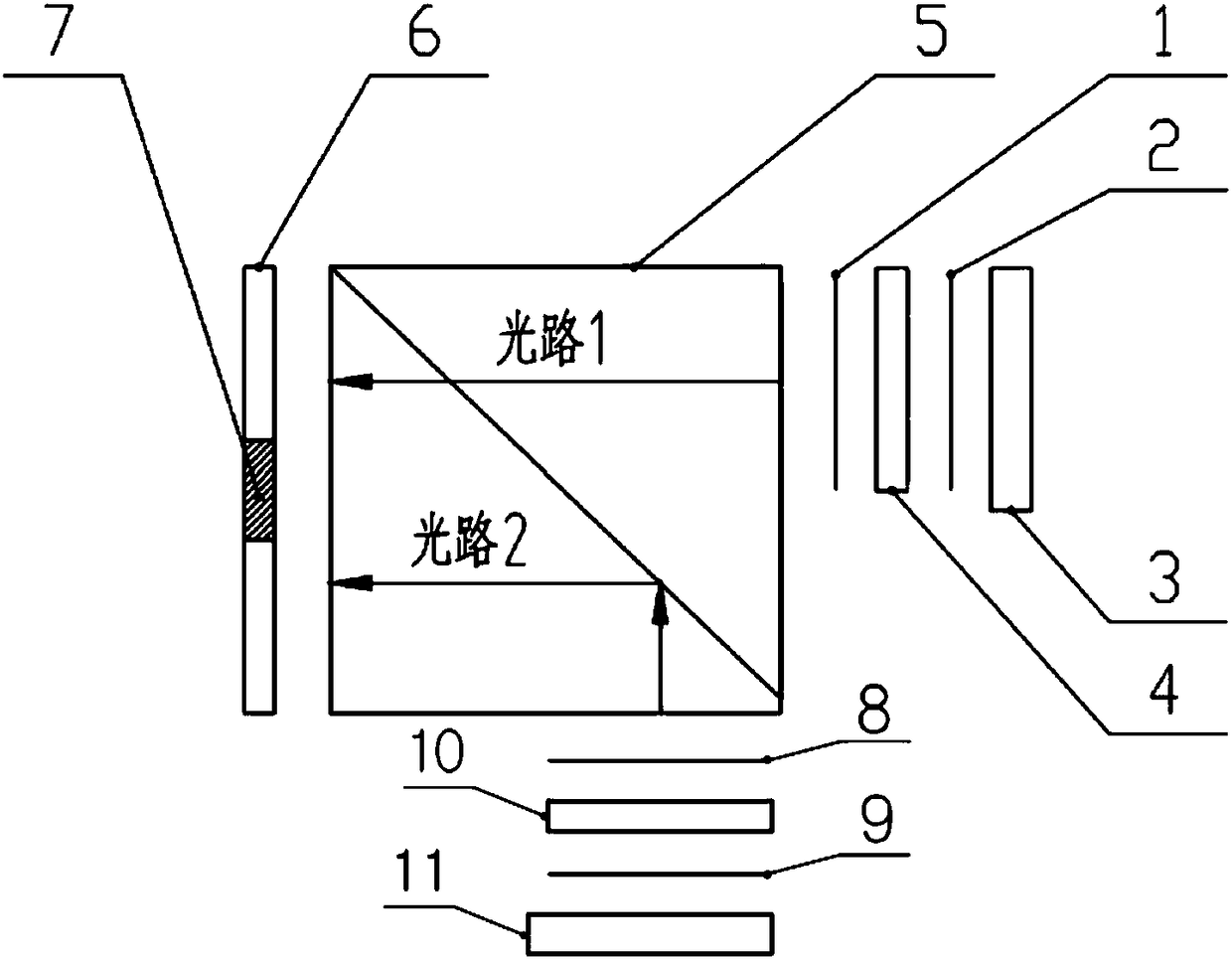

[0023] figure 1 A specific structural block diagram of the optical imaging system provided by Embodiment 1 of the present invention is shown, and for convenience of description, only parts related to the embodiment of the present invention are shown. In this embodiment, the optical imaging system includes: a polarization splitting device 5, a micro display module 6, a first polarized light source module and a second polarized light source module; The bonding part of the rectangular prism forms a light-splitting surface; the micro-display module 6 is spliced by two identical micro-displays; Adjacent to the equivalent focal plane, wherein, the P light of the first polarized light source module enters the polarization beam splitting device 5 vertically and completely passes through the beam splitting surface, and the S light of the second polarized light source module enters the polarization beam splitting device 5 vertically , and is reflected on the splitting surface at an a...

Embodiment 2

[0035] The target simulation system provided by Embodiment 2 of the present invention includes: a dual-channel control board and the optical imaging system described in Embodiment 1, the dual-channel control board is electrically connected to the optical imaging system, and is used to directly drive the optical imaging system miniature display module.

[0036] In this embodiment, one driver main board is used to drive two micro-displays, which ensures the consistency of the contrast and brightness uniformity of the two micro-displays.

Embodiment 3

[0038] The implementation flow of the splicing method for microdisplays provided by Embodiment 3 of the present invention is described in detail as follows:

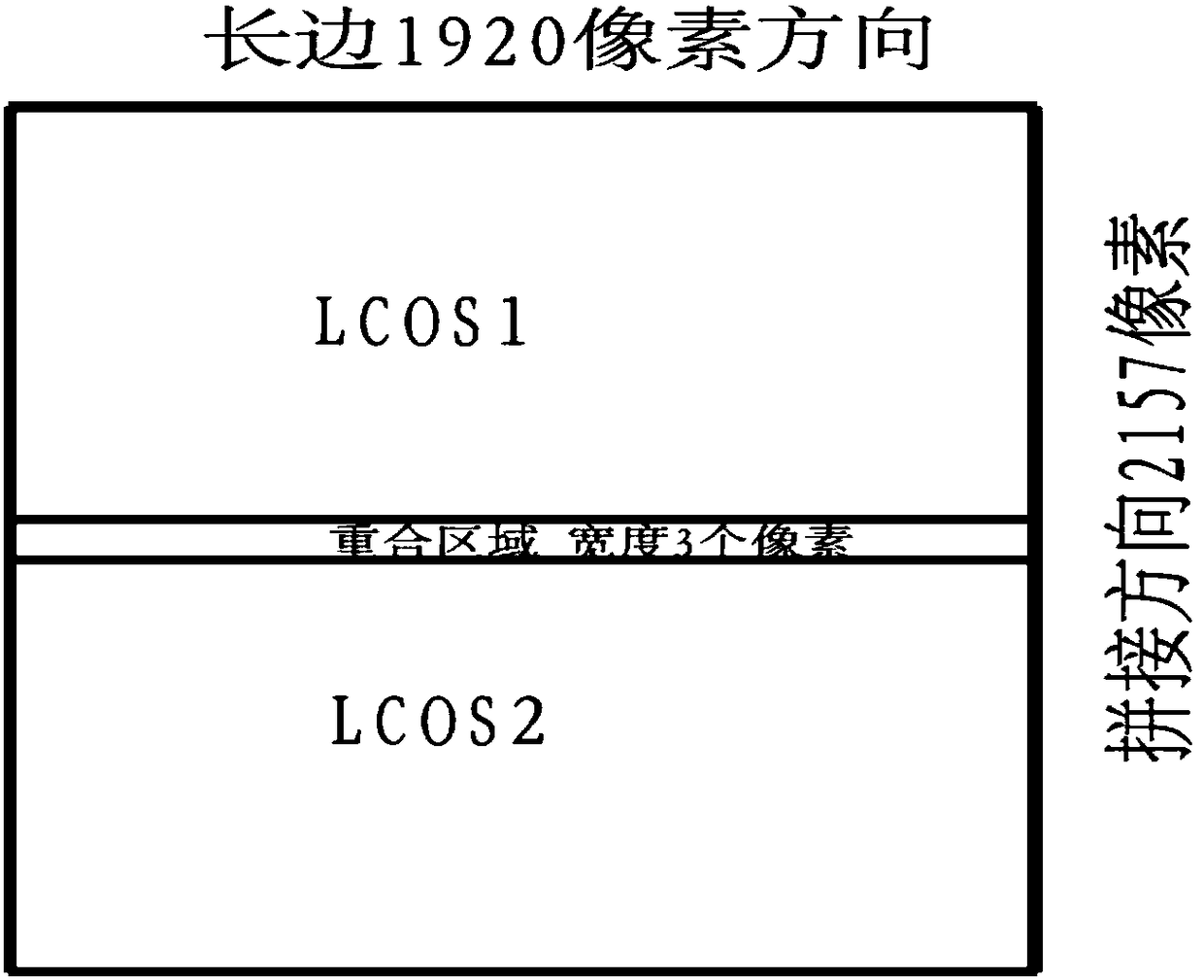

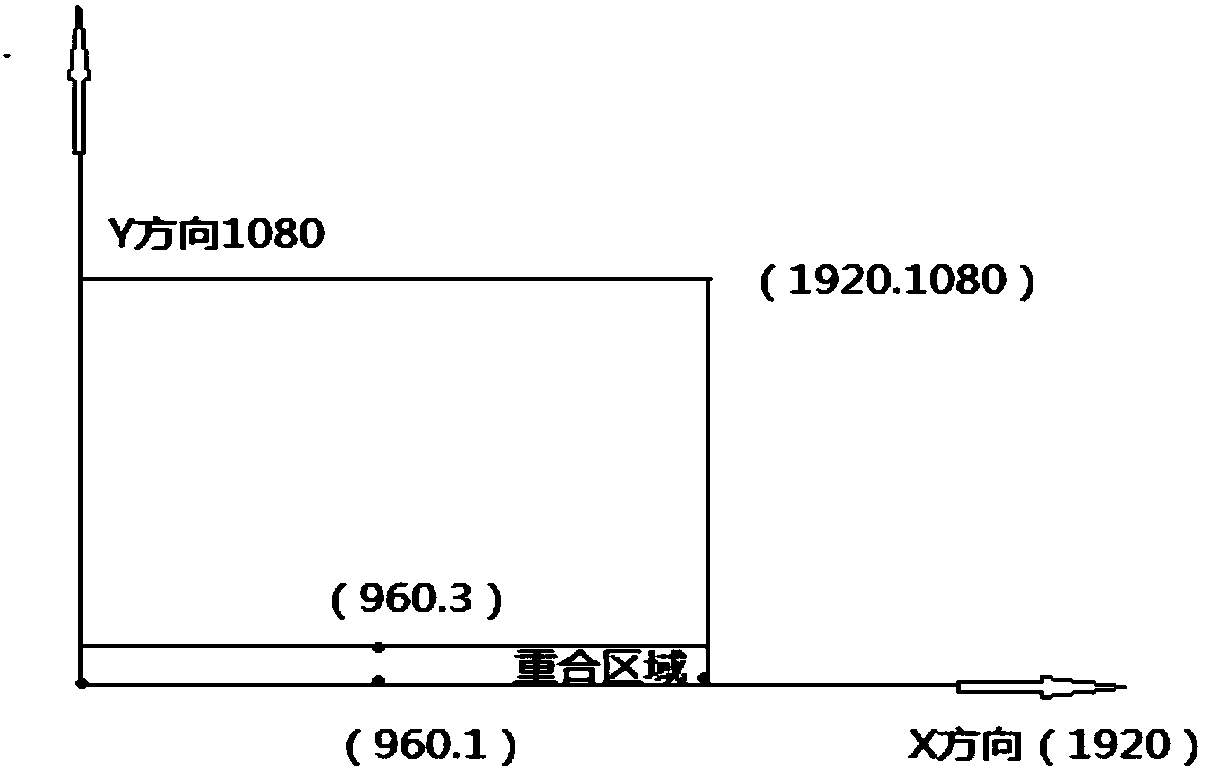

[0039] Such as figure 1 , 2 As shown, the second liquid crystal light valve 10 is installed on the optical platform, and the position of the first liquid crystal light valve 4 is adjusted using a six-dimensional precision turntable, so that the pixels that need to be overlapped are completely overlapped to meet the splicing accuracy requirements. At the same time of fine-tuning, it is necessary to set the second liquid crystal light valve 10 as a benchmark, and another piece of first liquid crystal light valve 4 is fine-tuned relative to the second liquid crystal light valve 10. The equipment used includes six-dimensional precision moving platform, two-dimensional moving platform, parallel Light pipe and theodolite. Stitching on the short side (1080 direction) has 3 pixels for coincidence accuracy, so the effective lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com