Method for preparing ceramic circuit board with dam and ceramic circuit board structure

A technology of circuit boards and ceramics, which is applied in the field of preparation of ceramic circuit boards with dams and the structure of ceramic circuit boards, can solve the problems of poor heat dissipation performance of dam adhesives, weak anti-ultraviolet ability, poor air tightness, etc., so as to improve the service life and environmental adaptability, improve adhesion strength and heat dissipation capacity, and reduce the effect of process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

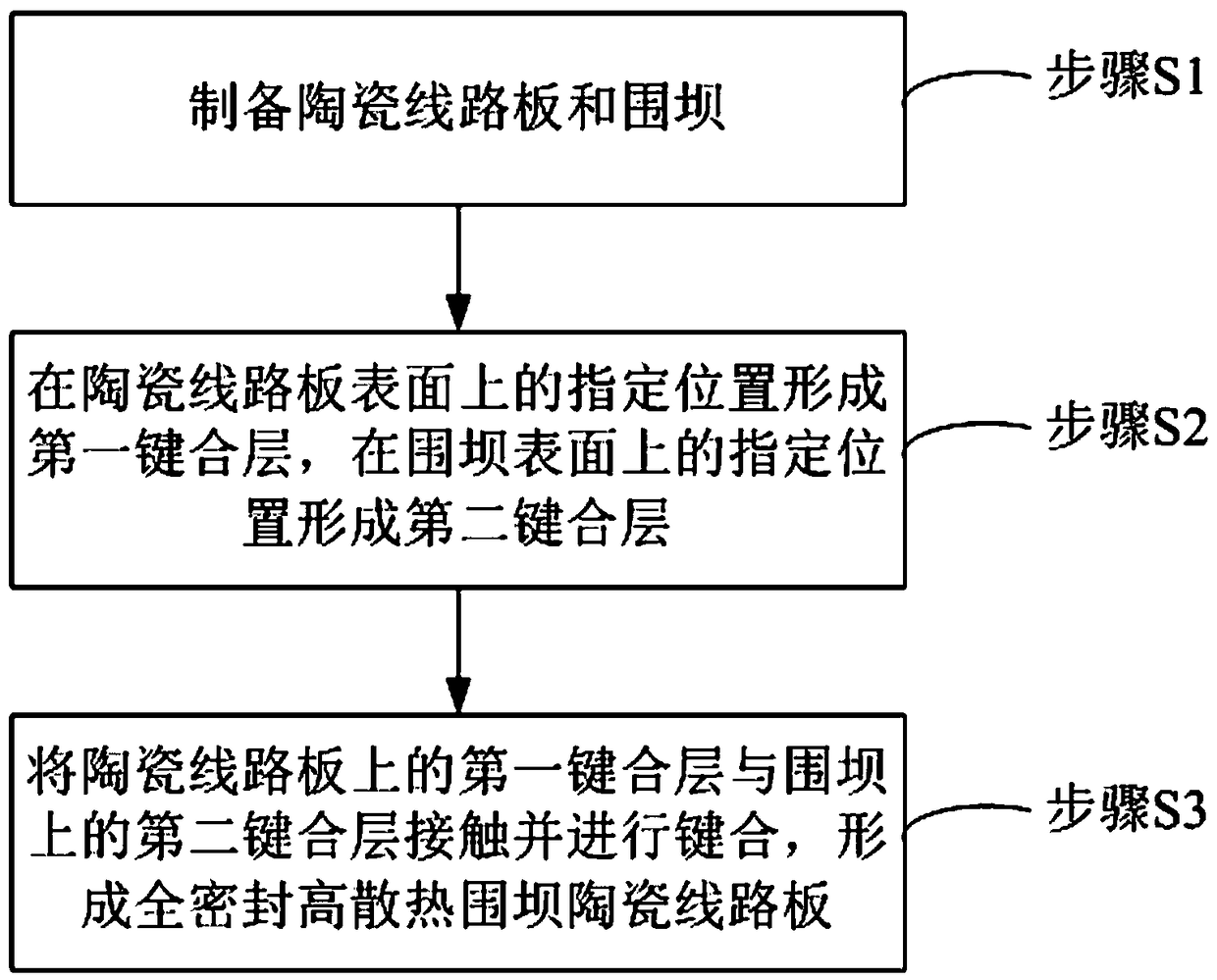

[0030] based on the following Figure 1 to Figure 9 , specifically explain the preferred embodiment of the present invention.

[0031] Such as figure 1 As shown, the present invention provides a method for preparing a ceramic circuit board with dams, and the prepared ceramic circuit boards with dams can be used in LED packaging modules, and can also be applied to other chip packaging modules.

[0032] The preparation method of a ceramic circuit board with a dam specifically comprises the following steps:

[0033] Step S1, preparing ceramic circuit boards and dams;

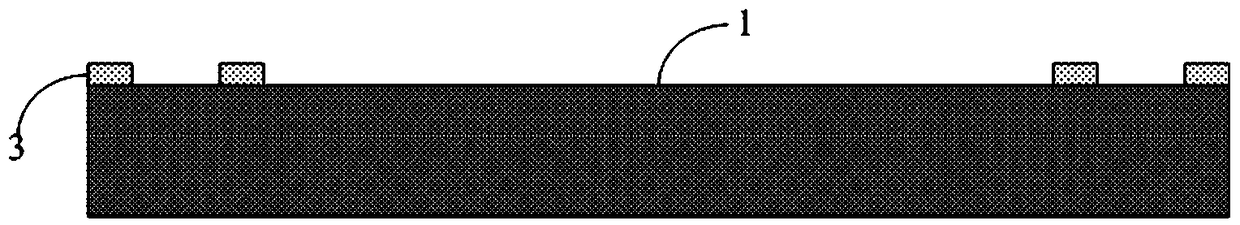

[0034] Step S2, such as figure 2 As shown, the first bonding layer 3 is formed at a specified position on the surface of the ceramic circuit board 1, such as image 3 As shown, a second bonding layer 4 is formed at a designated position on the surface of the dam 2;

[0035] Step S3, such as Figure 4 As shown, the first bonding layer 3 on the ceramic circuit board 1 is in contact with the second bonding laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com