Surface dehydrating method of cleaned Chinese chestnuts

A technique for washing chestnut after washing is applied in the field of surface dehydration after washing chestnut, which can solve the problems of bruising the pulp, affecting the quality of chestnut, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

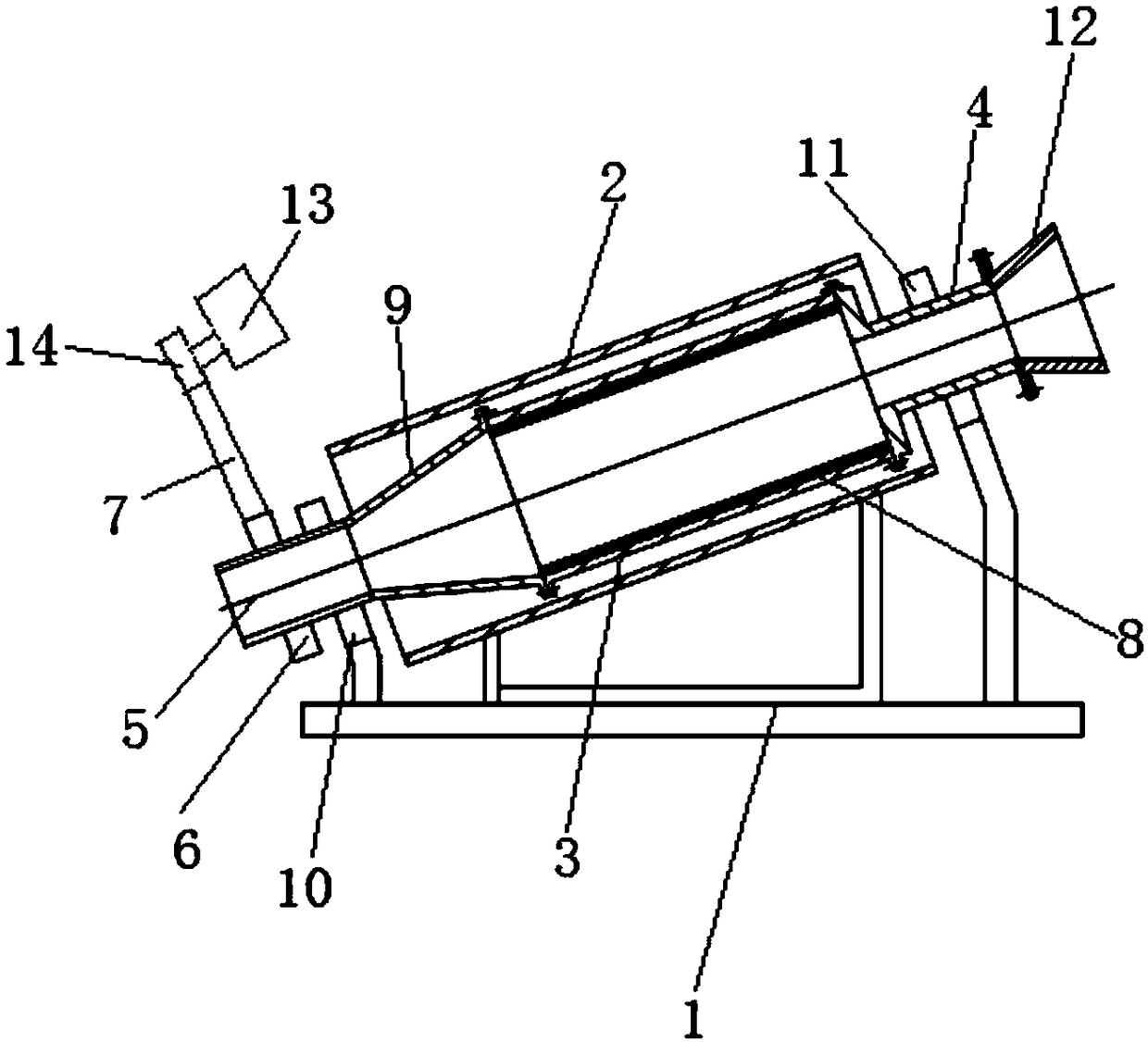

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] The surface dehydration method of a kind of chestnut after cleaning of the present invention, the chestnut after cleaning is put into the rotating drum 3, and the inner wall of rotating drum 3 is provided with bamboo fiber liner 8, see figure 1 , the outer coaxial sleeve of the rotating drum 3 has a fixed cylinder 2, and the wall of the rotating drum 3 is evenly distributed with water-permeable holes. By rotating the rotating drum 3, the chestnuts slide relative to the bamboo fiber lining 8, so that the surface of the chestnuts Moisture is wiped by bamboo fiber lining 8, and the moisture absorbed on the bamboo fiber lining 8 is thrown in the fixed cylindrical body 2 through the permeable hole under the effect of centrifugal force, and finally flows out from the fixed cylindrical body 2 again.

[0019] The fixed cylinder 2 is obliquely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com