Welding process method of adding cobalt-based hardened layer on opening pipeline end portion

A welding process and hardening layer technology, which is applied in the welding process field of adding a cobalt-based hardening layer at the end of an open pipe, and can solve problems such as surface cracking of the surfacing layer, deformation of surfacing parts, and difficulty in ensuring the quality of hardening layer parts. , to achieve the effect of simple welding operation and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below through specific examples.

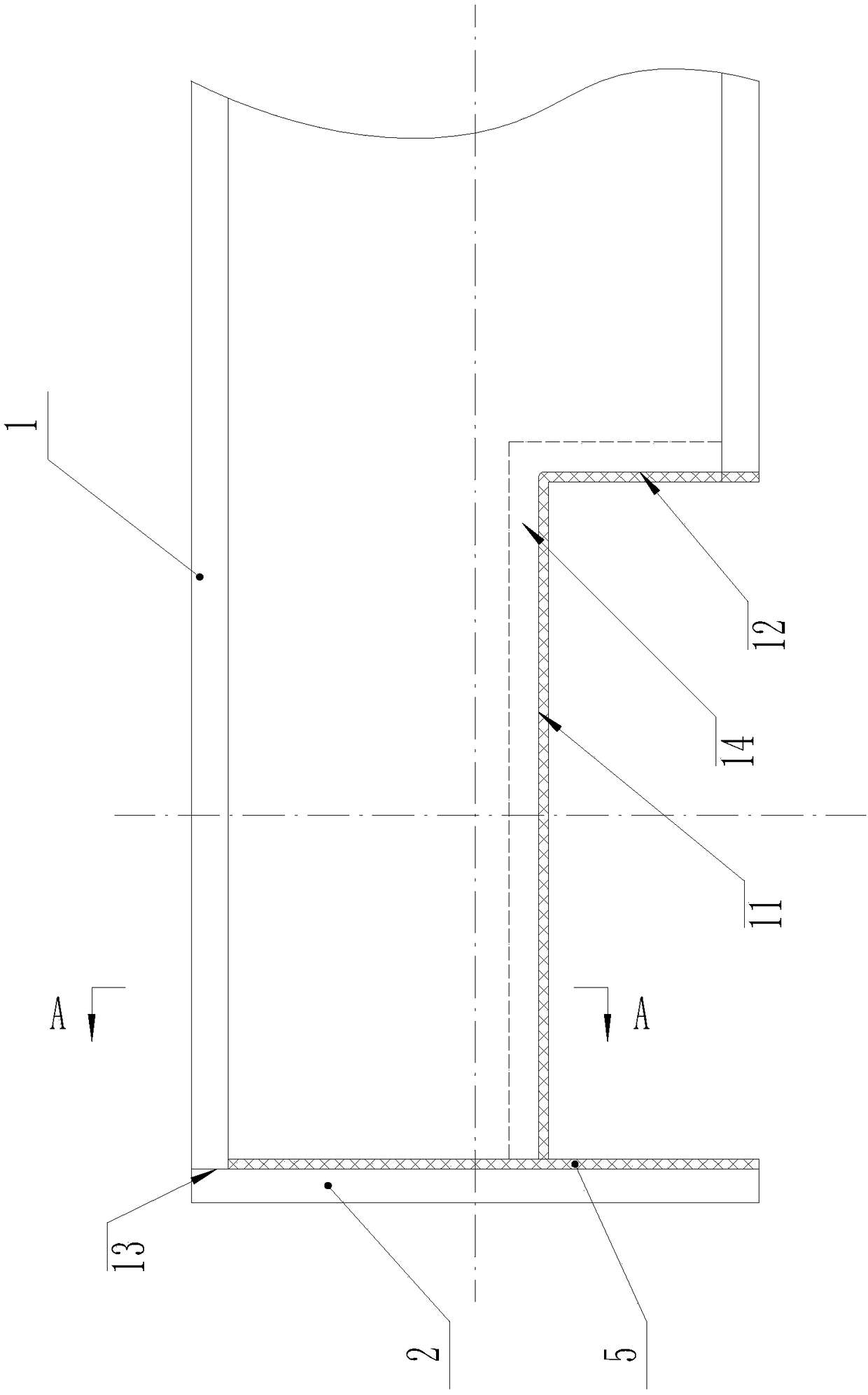

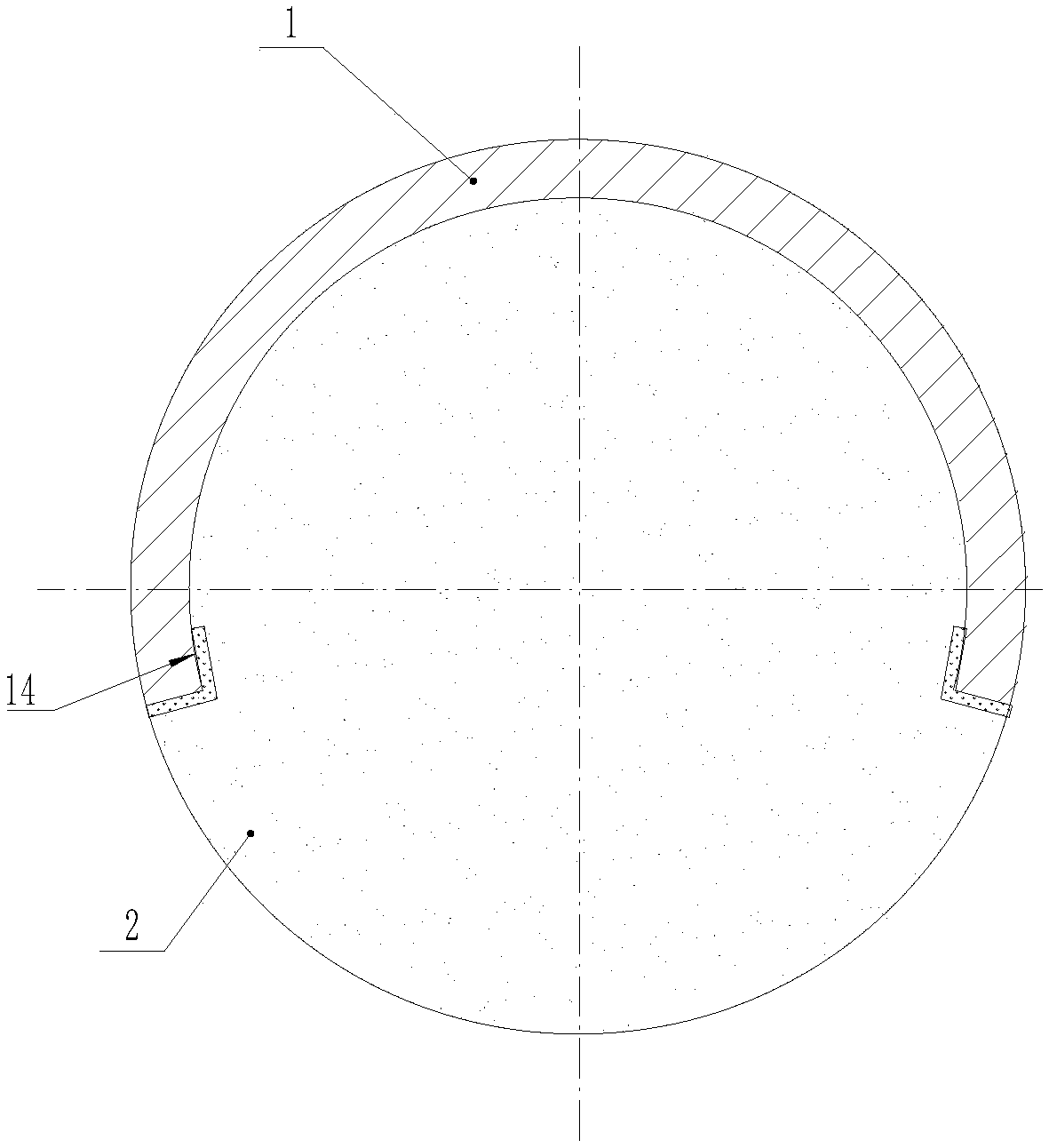

[0050] Such as Figure 1 to Figure 8 Shown, a kind of welding process method that increases cobalt-based hardening layer at the end of open pipeline, it comprises the following steps:

[0051] S1. Provide an end plate, the front of the end plate is surfacing with cobalt-based welding materials to form a cobalt-based hardening layer that matches the shape of the inner hole of the open pipeline;

[0052] Wherein, the method for overlaying the front of the end plate in the step S1 includes the following steps:

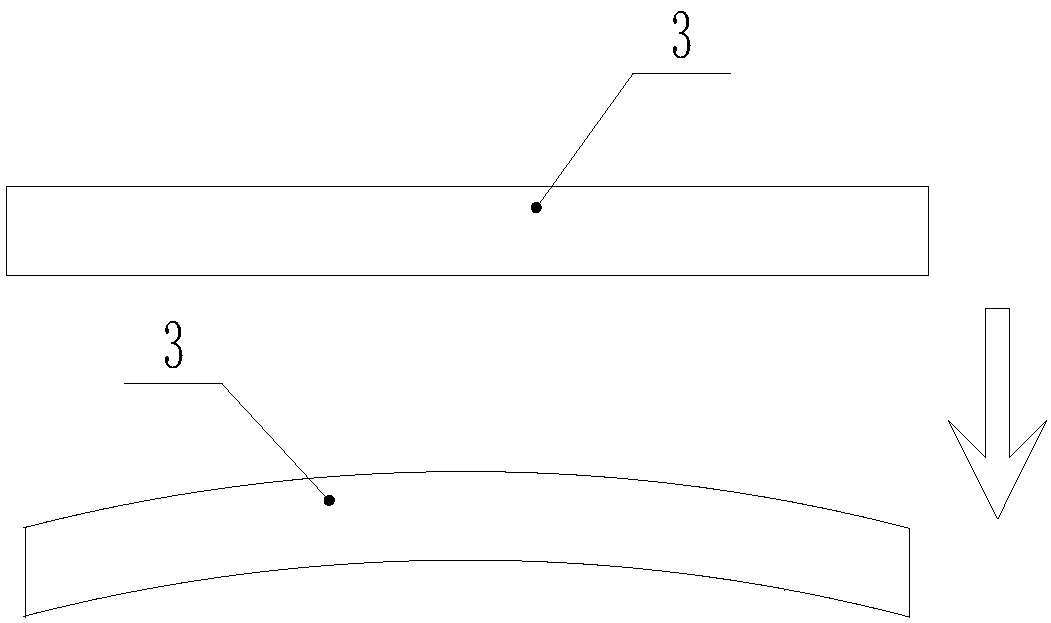

[0053] S11. Reversely pre-bend the circular blank for making the end plate, the arched side is the front side, and the size of the circular blank is larger than the diameter of the pipe, such as image 3 shown;

[0054] S12, cleaning the blank before welding, cleaning the oil stains and dirt on the surface of the blank with acetone solution;

[0055] S13. Draw a surfaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com