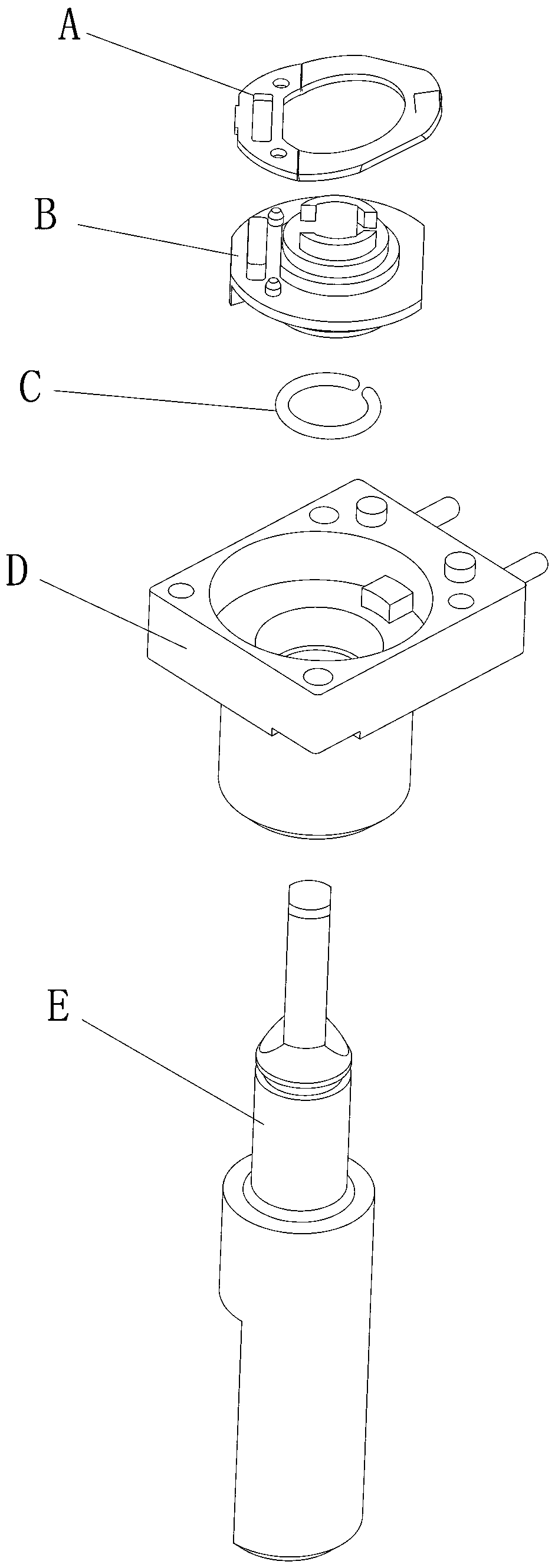

Potentiometer assembling machine with automatic retainer ring mounting function

A potentiometer and assembly machine technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency, low installation quality, and pushing the collar into the card slot, so as to improve production efficiency and quality, Improve efficiency and quality, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Refer to attached figure 1 To attach Figure 10 The specific embodiment of the present invention is introduced.

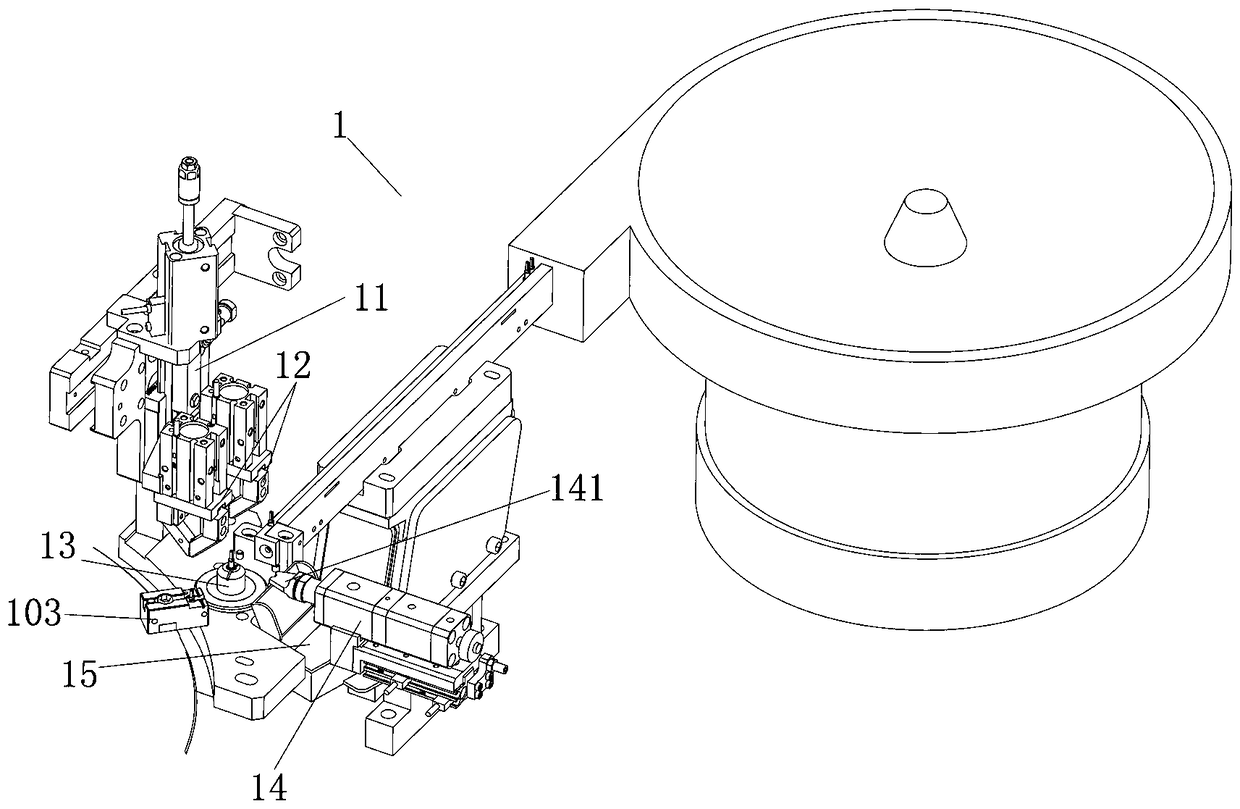

[0034] Such as Figure 1-10 As shown in the figure, a potentiometer assembly machine for automatically installing collars includes an assembly table 10 with a turntable 101 that rotates at intervals in the center. A plurality of jigs 103 are arranged on the turntable 101 at equal angles, and the turntable 101 is arranged sequentially according to the direction of rotation. Shaft core feeding device 1, shaft sleeve feeding device 2, collar feeding device 3, shaft sleeve oiling device 4, collar pressing device 5, stop seat and shrapnel feeding device 75, the stop seat and The pressure riveting device 8 and the unloading device 9 for shaft core riveting, the rear of the stop seat and the shrapnel feeding device 75 are connected with a shrapnel riveting device 7, and the shrapnel riveting device 7 is connected with a shrapnel material tape reel 102 and a stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com