Variable-diameter circular sheet fixture structure and method

A fixture and circular technology, applied in the field of grinding processing, can solve the problems of affecting the production progress, long time for fixture replacement, etc., to achieve the effect of improving processing quality, easy handling and installation, and small total weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] As introduced in the background technology, there are deficiencies in the prior art. In order to solve the above technical problems, the present application proposes a variable-diameter circular sheet clamp structure.

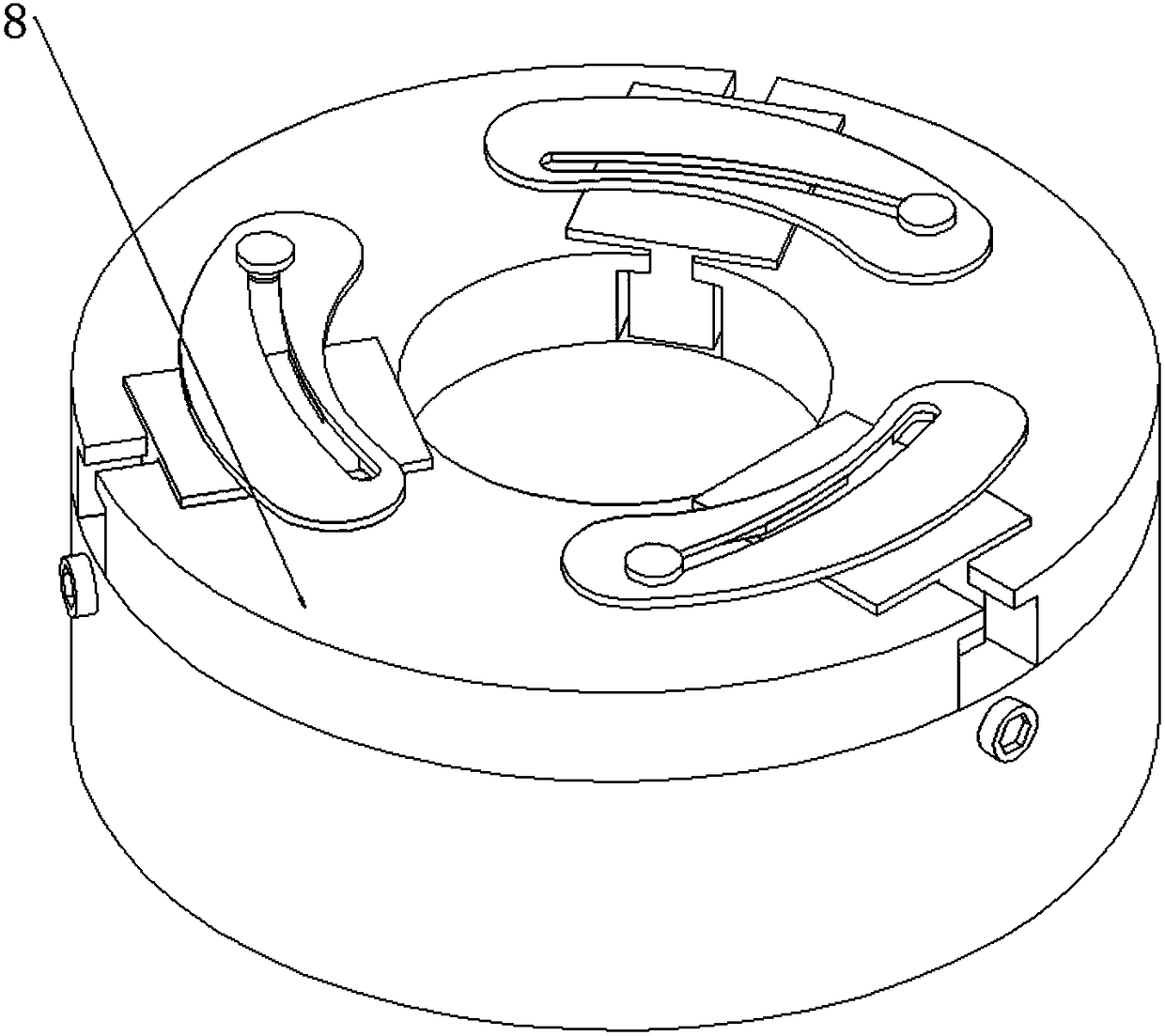

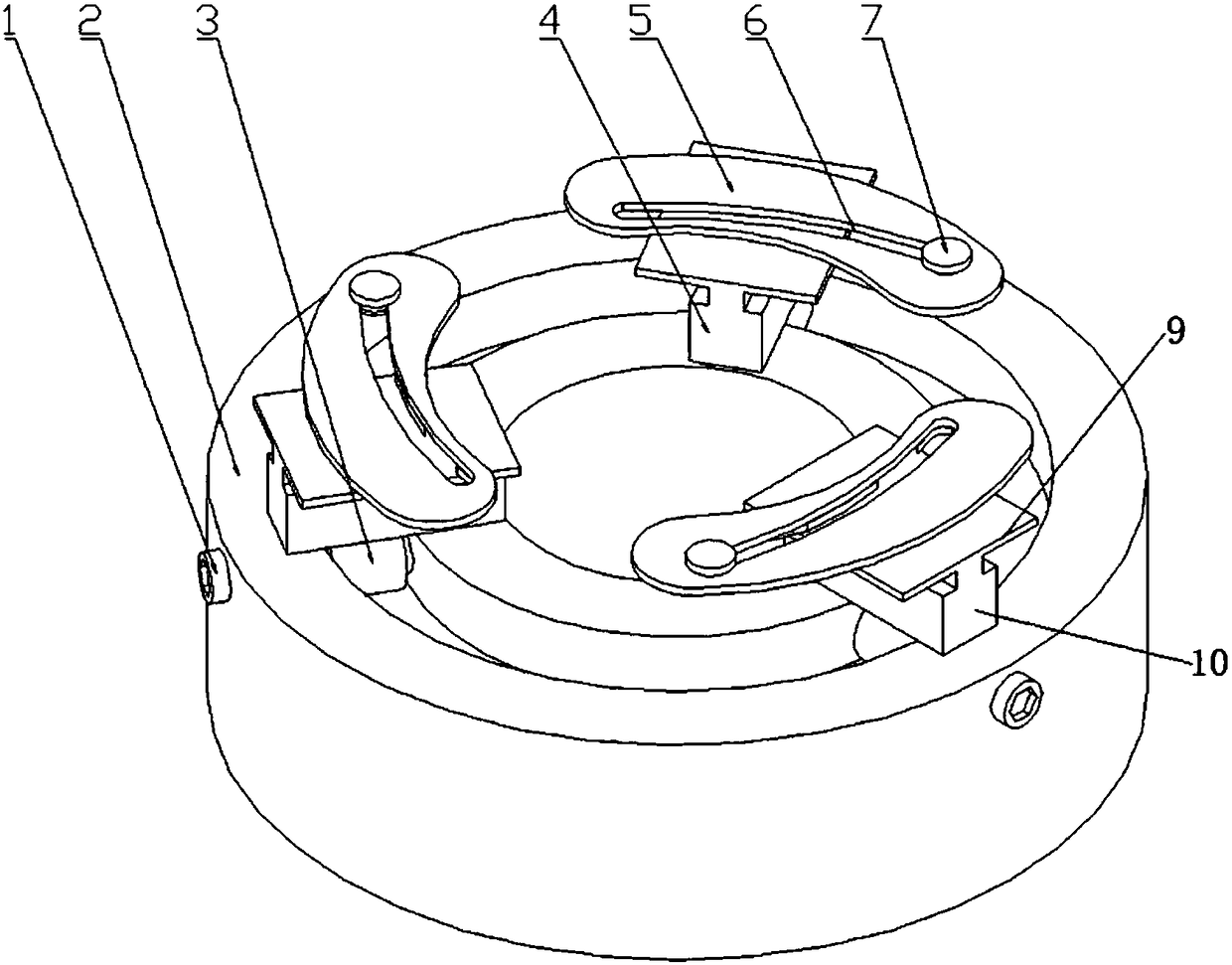

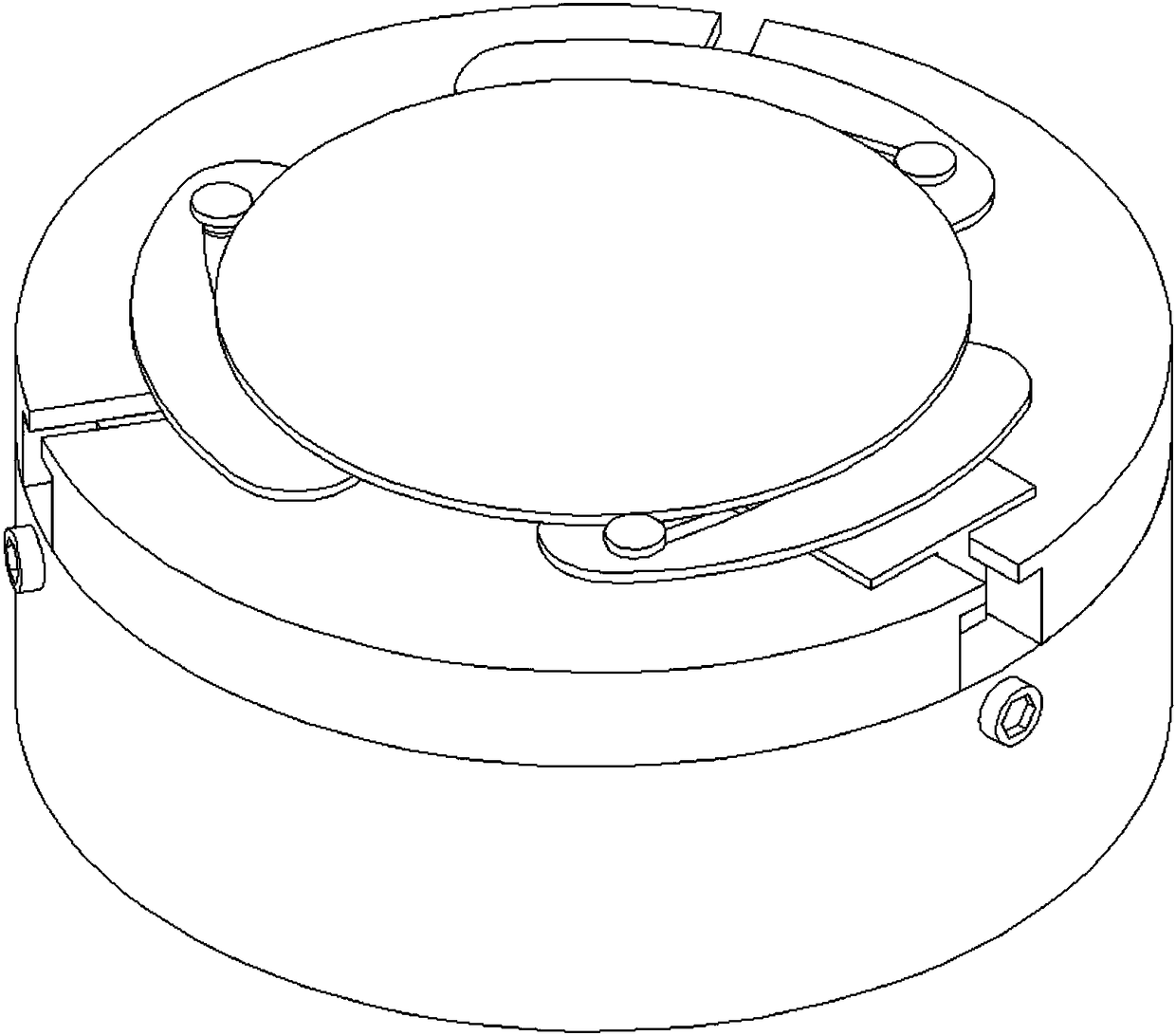

[0043] In a typical implementation of the present application, such as figure 1 As shown, a variable-diameter circular sheet clamp structure includes a clamp base 2 with an annular groove on the surface, a clamp cover 8 and at least one clamp, the clamp includes a screw 3, and the screw 3 is along the diameter of the annular groove Set in the annular groove and one end of the lead screw passes through the outer wall of the fixture base 2, the lead screw 3 cooperates with the movable clamp 4 to drive the movable clamp 4 to move, and the surface of the movable clamp 4 is provided with a chuck with a chuck groove 6 5. The bayonet pin 7 can move freely in the chuck groove 6, and the workpiece to be processed is arranged on the surface of the chuck 5. The bay...

Embodiment 2

[0054] The present invention also provides a grinding machine, which adopts the variable-diameter circular sheet clamp structure described in Embodiment 1.

Embodiment 3

[0056] A method for using a variable-diameter circular sheet clamp structure, comprising the following steps:

[0057] 1) Fix the fixture base on the processing platform with bolts;

[0058] 2) According to the size of the sheet to be processed, use the hexagonal wrench to adjust the movable clamping plate to the proper position. The three fixtures can be adjusted separately or at the same time. Each adjustment must ensure the same angle set by the inner hexagonal rotation;

[0059] 3) Place the sheet to be processed at the center of the fixture structure, adjust the bayonet position so that the bayonet is in direct contact with the sheet to be processed, turn the lead screw again, and realize the fixing of the sheet to be processed by the force self-locking of the bayonet;

[0060] 4) Start processing parts;

[0061] 5) After the processing is completed, use a hexagonal wrench to reversely turn the screw, the bayonet self-locking disappears, and the workpiece is removed;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com