Force control joint device capable of keeping output force constant

A technology of outputting force and joints, applied in the field of robotics, can solve problems such as unstable contact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

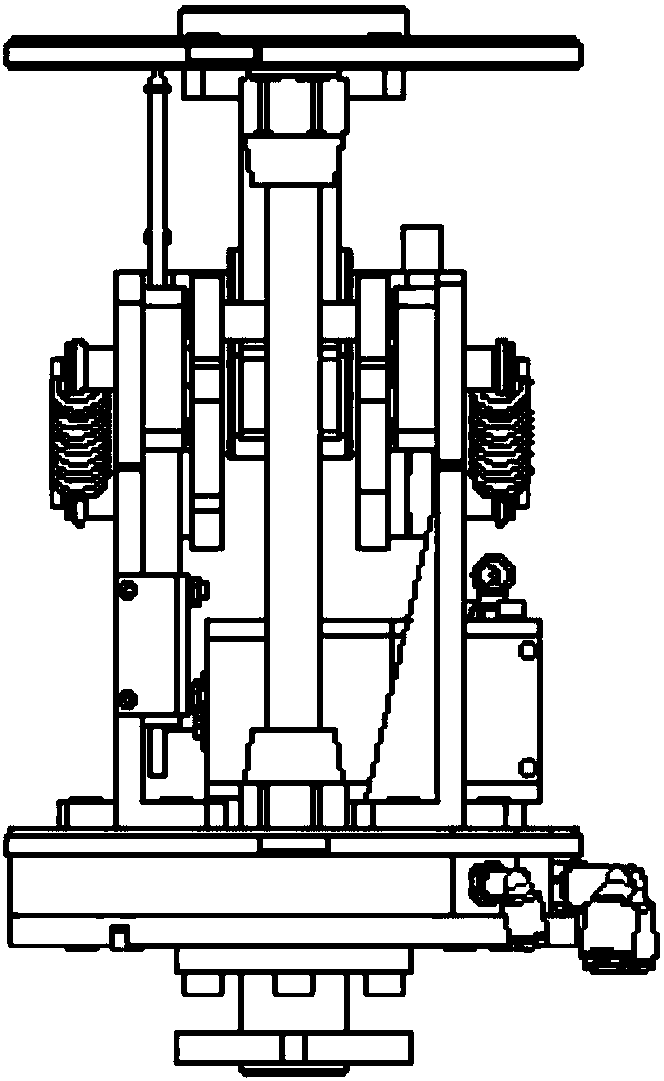

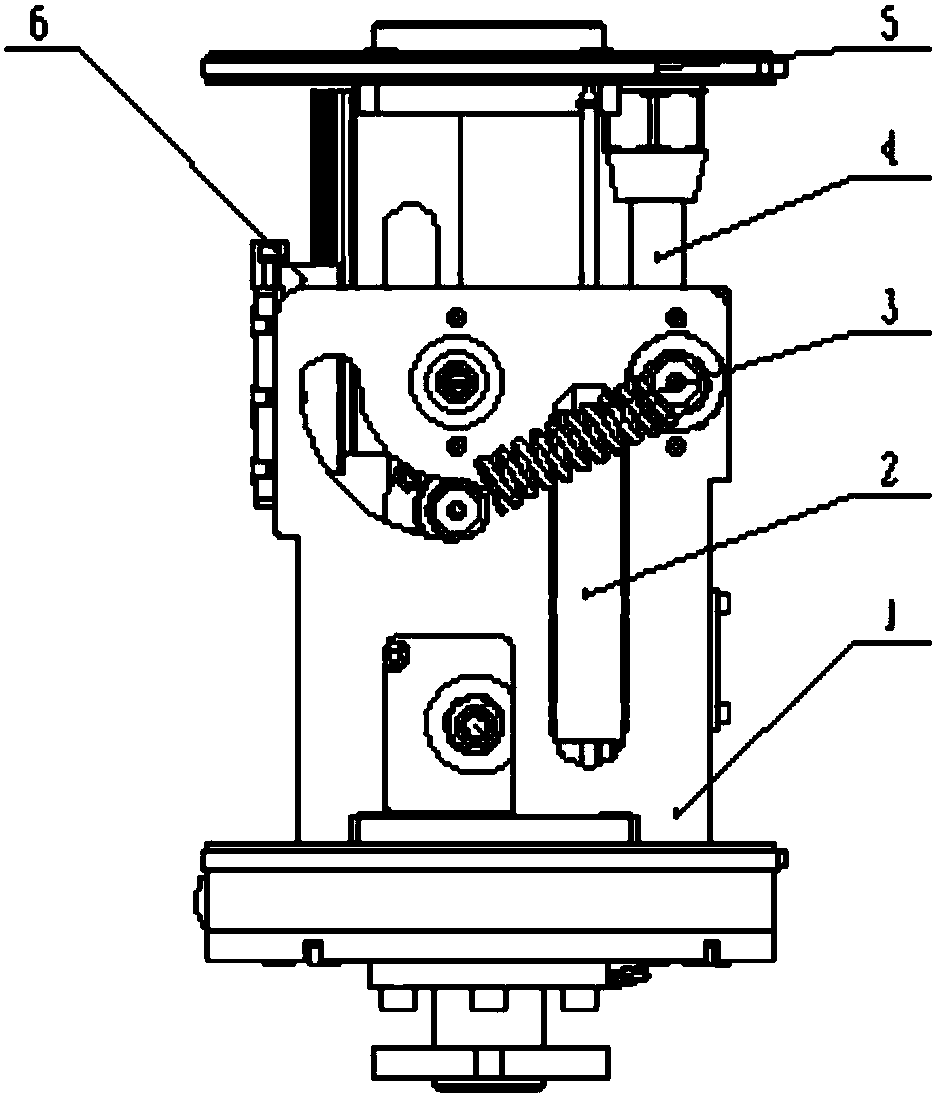

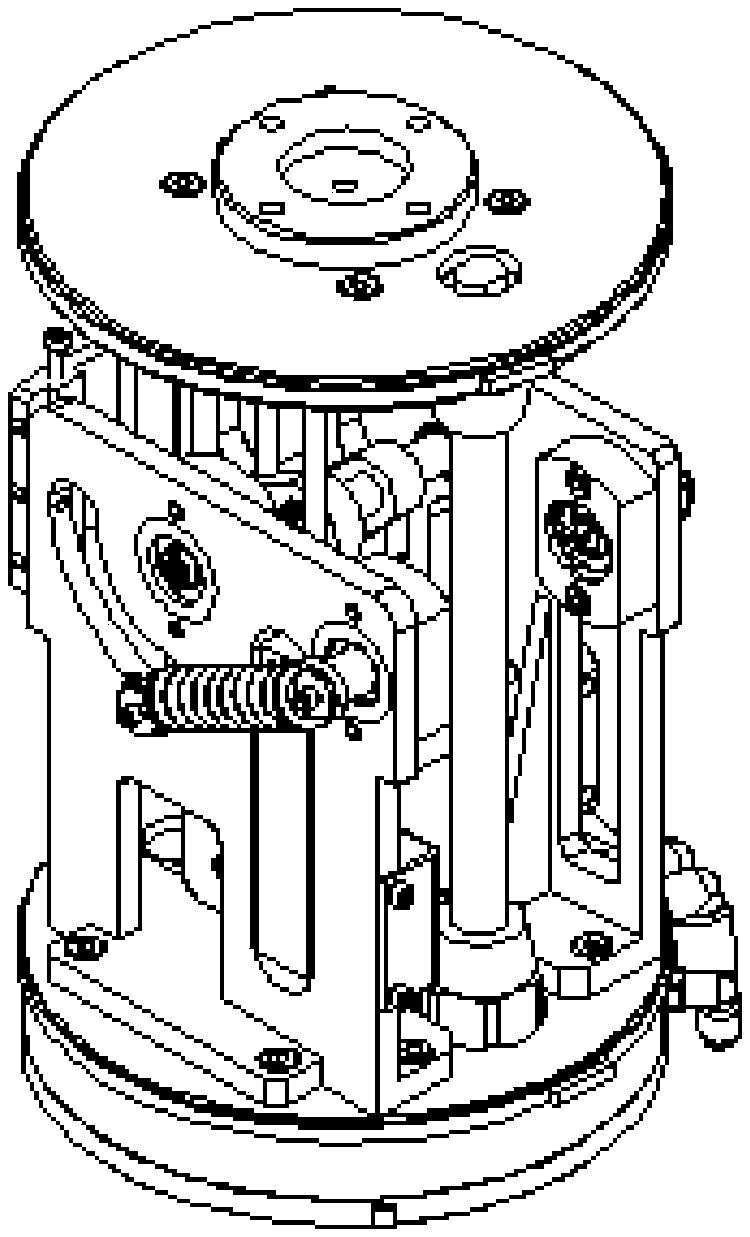

[0029] Figure 1 and figure 2 What is shown is a force-controlled joint device for keeping the output force constant according to an embodiment of the present invention, including:

[0030] base (1), displacement sensor (2), elastic mechanism component (3), pneumatic muscle structure component (4), output end (5), guide rail component (6),

[0031] Among them, the base (1) provides support for the elastic mechanism component (3), the displacement sensor (2), the pneumatic muscle structure component (4) and the guide rail component (6), and can adjust the air pressure in the pneumatic muscle structure component (4) ; The output end (5) includes the upper joint (28) of the pneumatic muscle structure component and the bolt hole (29) of the connecting rod seat; the elastic mechanism component (3), and the pneumatic muscle structure component (4) work together to control the force control joint The output of the device; the force-displacement sensor (2) is used to measure the join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com