Closed-mouth zipper cutting-off machine

A cutting machine and zipper technology, applied in the field of zipper manufacturing, can solve the problems of high cost, low efficiency, high noise pollution, etc., and achieve the effects of improving quality, improving production efficiency and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

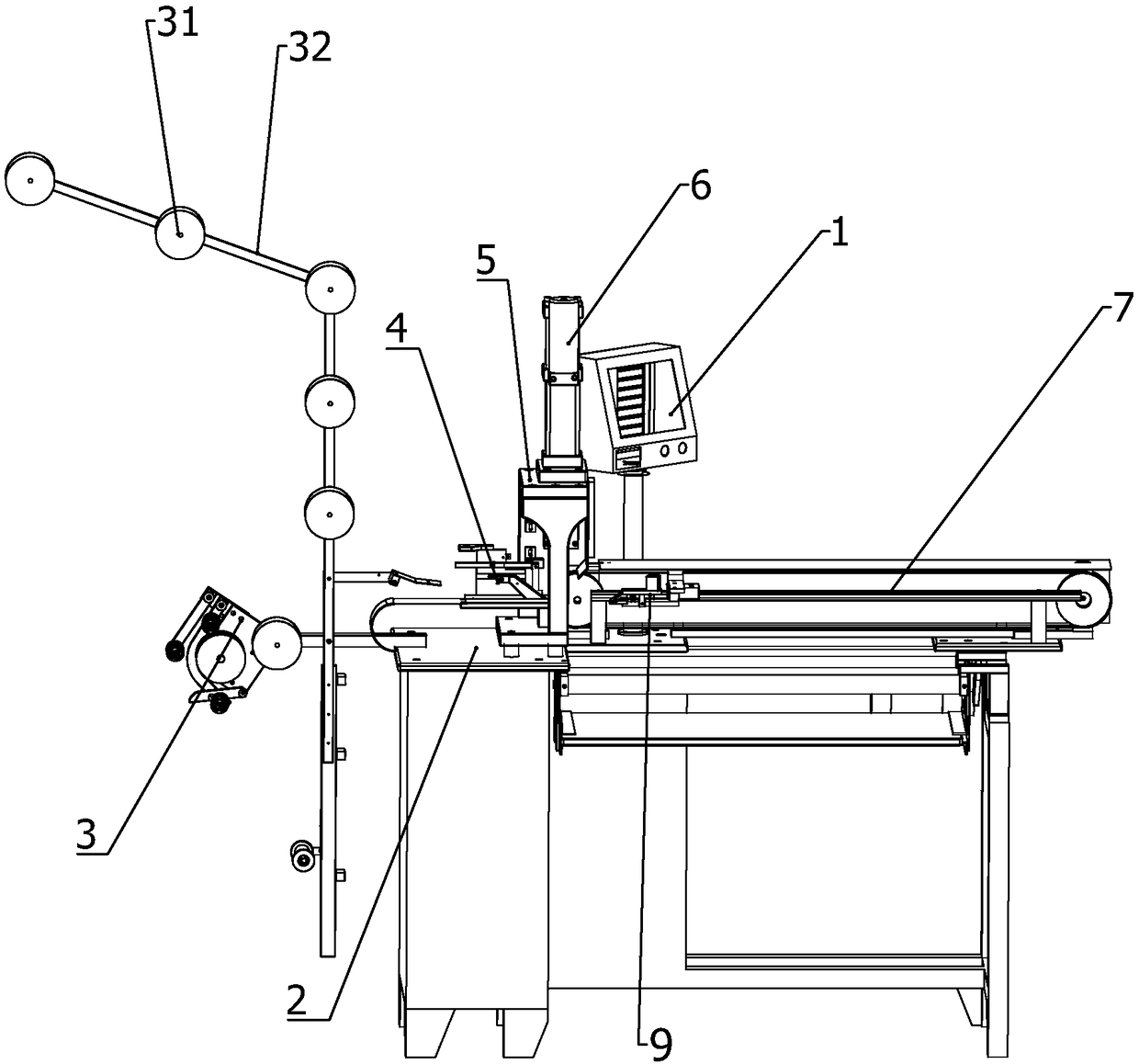

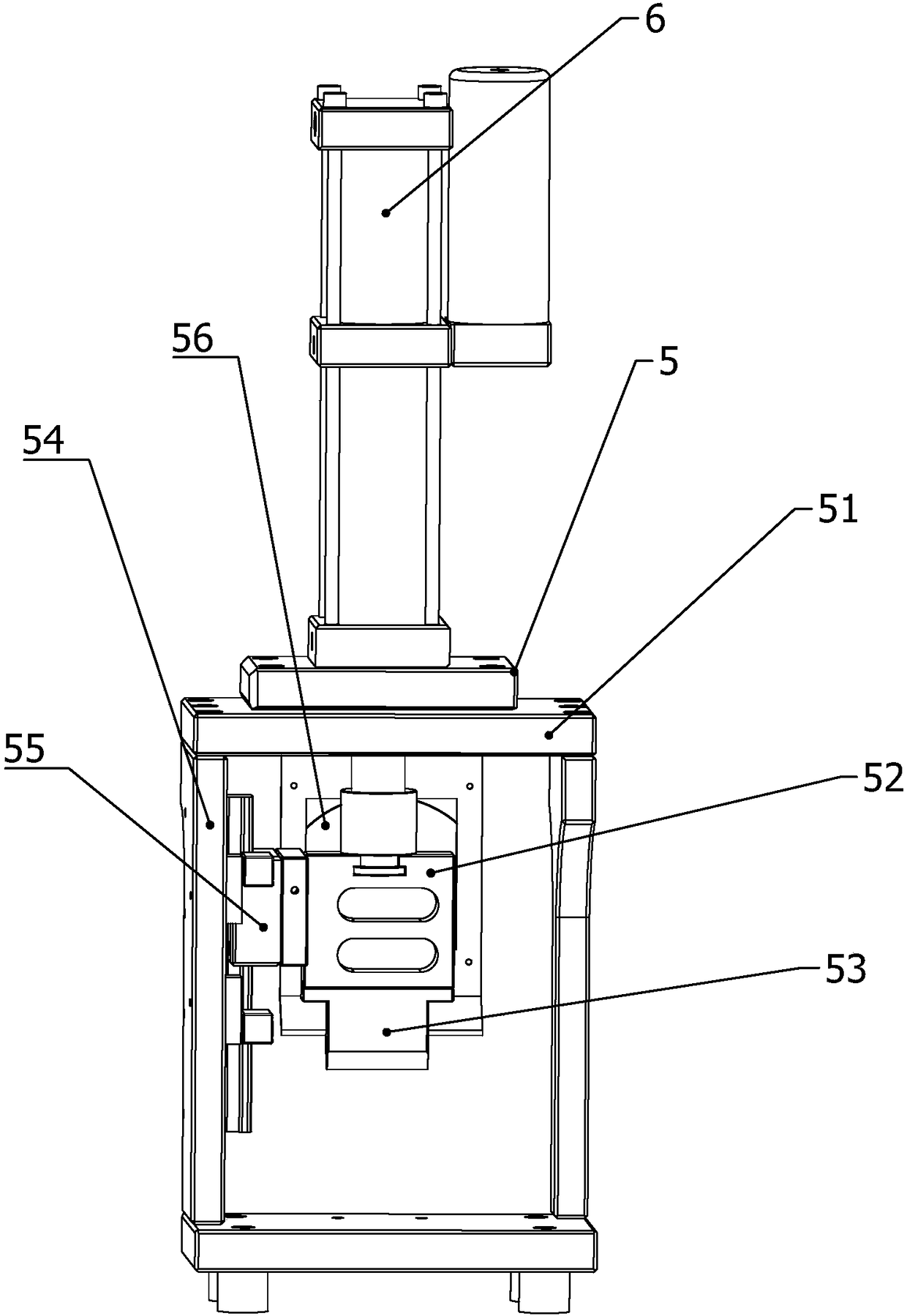

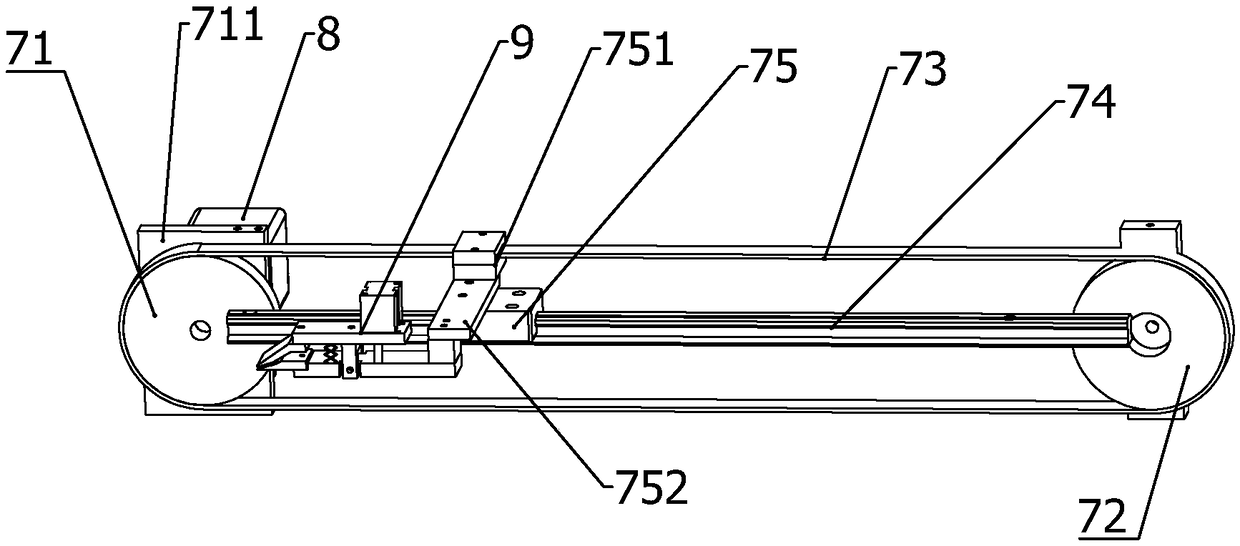

[0018] Such as Figure 1 to Figure 4 As shown, it includes a control device 1, a frame 2, a feeding device 3 installed on the frame 2, a chain pressing device 4, and a cutting device 5. The feeding device 3 is arranged on one side of the cutting device 5, and also includes an auxiliary cutting device. The towing device 7 of the device 5 is characterized in that: the cutting device 5 includes a bracket 51 installed on the frame 2, the bracket 51 is provided with a cutter device, and the cutter device includes a knife rest 52. The pneumatic hydraulic cylinder 6 that drives the knife rest 52 to move up and down and the cutter head 53 located at the lower end of the knife rest 52, the support 51 is also provided with a slide rail 54 distributed up and down, and the slide rail 54 is provided with a relative A slide block 55 slidable on the slide rail 54, the slide block 55 is fixedly connected to one side of the knife rest 52, and the side of the support 51 opposite to the knife re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com