Plank paper-pasting equipment with automatic feed system

An automatic feeding and wood board technology, applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers, can solve the problems of time-consuming, labor-intensive, inconvenient to use, etc., achieve uniform gluing, improve production efficiency, and easy to use and adjust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

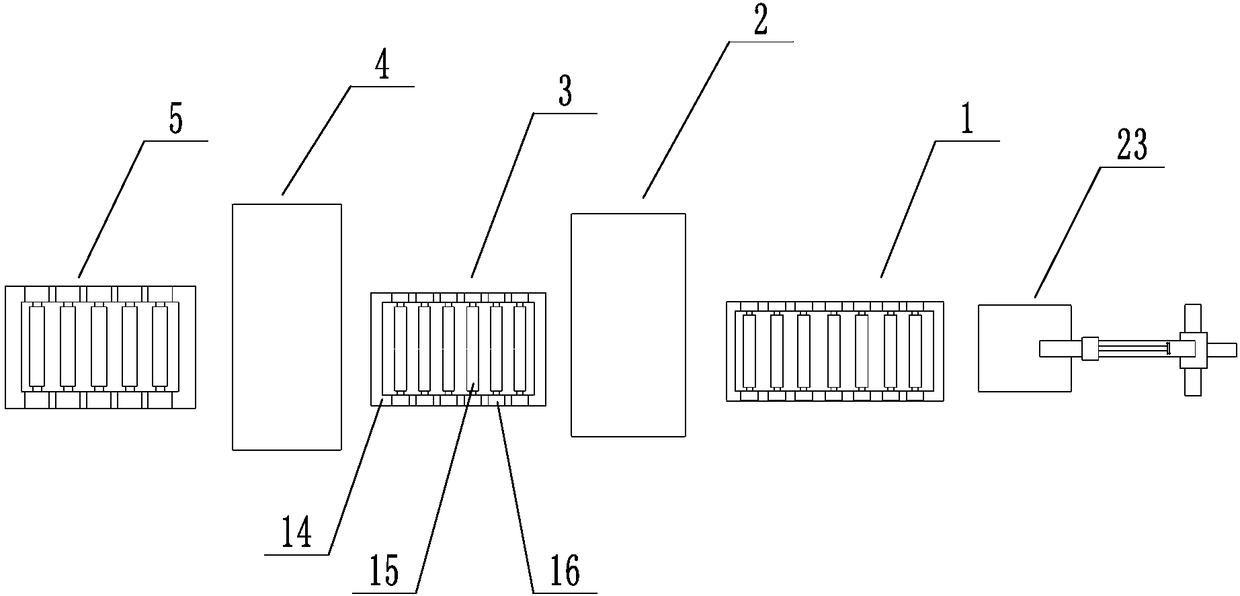

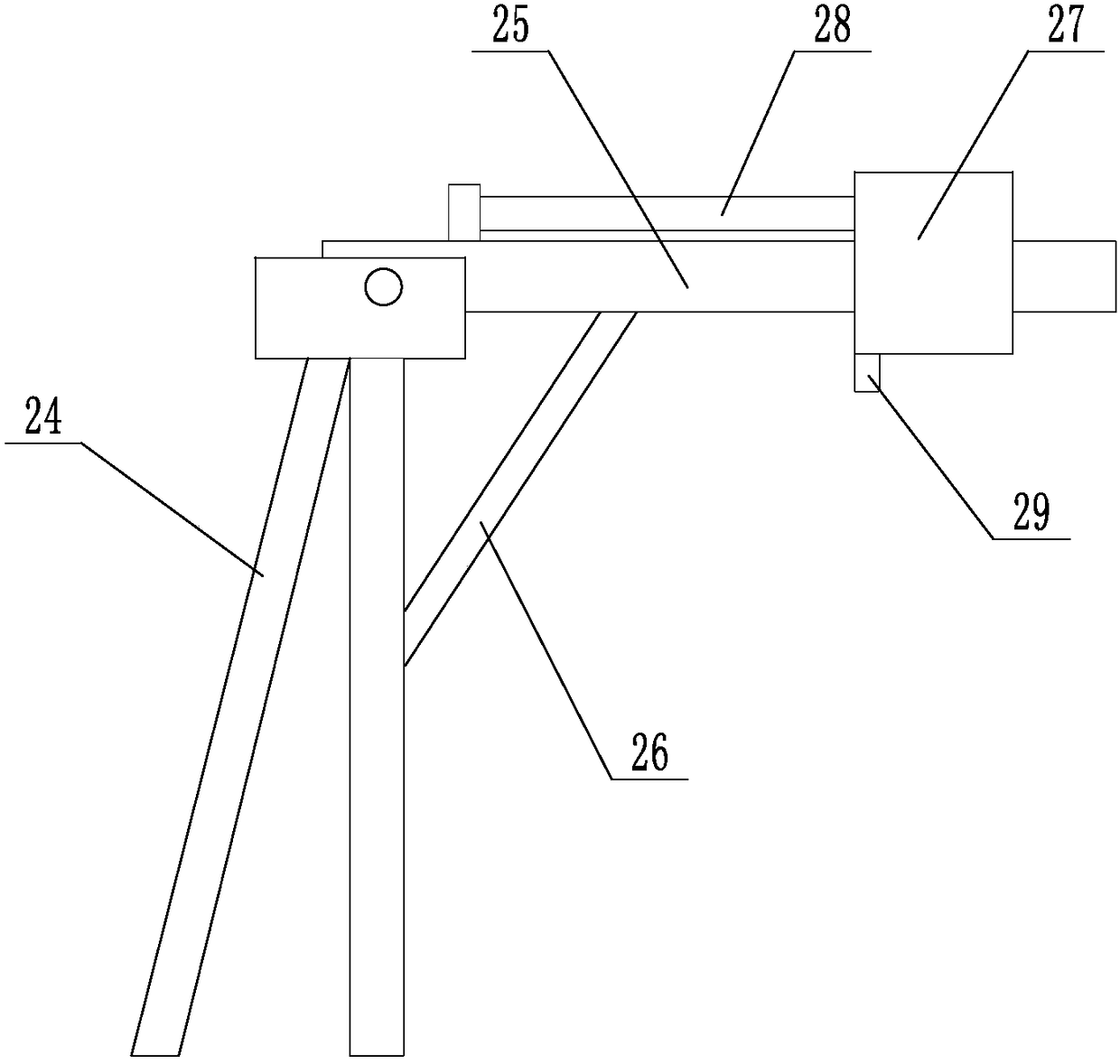

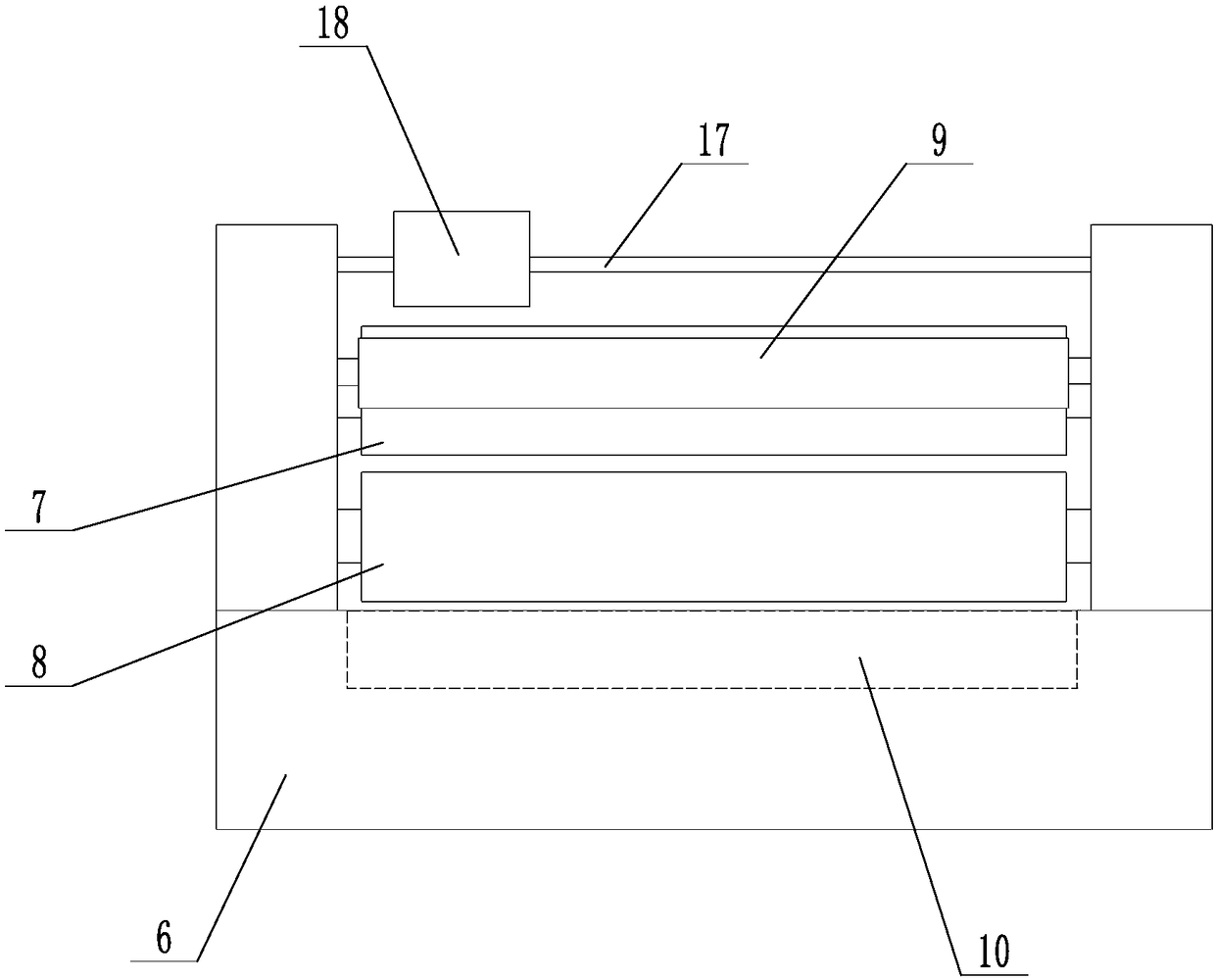

[0019] Such as Figure 1 to Figure 5 As shown, a wooden board sticker equipment with an automatic feeding system includes a pushing device, a lifting platform 23, a first conveying platform 1, a gluing device 2, a second conveying platform 3, and a pressing device arranged in sequence along the conveying direction of the wooden board 4 and the third delivery platform 5, the pushing device includes a mounting frame 24, the top of the mounting frame 24 is hinged with a cantilever 25, the mounting frame 24 is provided with a first cylinder 26 for driving the cantilever 25 to rotate, and the cantilever 25 is movably provided with The driving block 27 and the second air cylinder 28 for driving the driving block 27 to move, the driving block 27 is provided with a push plate 29 for pushing the wooden board towards the first conveying table 1, and the gluing device 2 includes the first machine base 6 , the first base 6 is rotatably provided with a glue roller, the glue roller includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com