Exhaust method for thermosetting forming process

A molding process and vent hole technology, which is applied in the field of thermosetting molding process venting, can solve problems such as poor control of venting, and achieve the effects of shortening hot-press curing time, reducing venting procedures, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

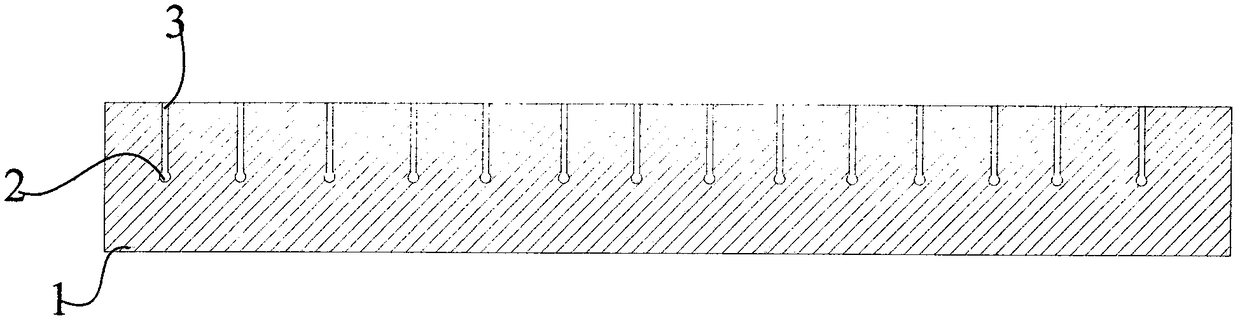

[0019] Example 1, such as figure 1 As shown, this embodiment provides a method for exhausting the thermosetting molding process

[0020] This embodiment aims to solve the exhaust problem existing in the exhaust process of the existing thermosetting molding process. Therefore, this embodiment improves the mold itself in order to achieve the purpose of automatic exhaust. To this end, this embodiment provides a method for exhausting heat during the thermosetting molding process.

[0021] The method for exhausting the thermosetting molding process provided by this embodiment first provides an exhaust hole on the mold wall of the mold, specifically, an exhaust hole 2 is opened at the center of the wall thickness of the mold 1 or at a position upward from the center The main purpose of opening the vent hole 2 at this position is to ensure the stability of the overall structure of the mold, and to uniformly process the deep gap 3 on the inner surface of the mold. The width of the de...

Embodiment 2

[0025] Example 2, such as figure 1 As shown, this embodiment provides a method for exhausting the thermosetting molding process

[0026] This embodiment aims to solve the problems existing in the exhaust process of the existing thermosetting molding process. Therefore, this embodiment improves the mold itself in order to achieve the purpose of automatic exhaust. To this end, this embodiment provides a method for exhausting heat during the thermosetting molding process.

[0027] The method for exhausting the thermosetting molding process provided by this embodiment first provides an exhaust hole on the mold wall of the mold, specifically, an exhaust hole 2 is opened at the center of the wall thickness of the mold 1 or at a position upward from the center The main purpose of opening the vent hole 2 at this position is to ensure the stability of the overall structure of the mold 1, and to uniformly process deep gaps on the inner surface of the mold 1. The width of the deep gap 3...

Embodiment 3

[0031] Example 3, such as figure 1 As shown, this embodiment provides a method for exhausting the thermosetting molding process

[0032] This embodiment aims to solve the problems existing in the exhaust process of the existing thermosetting molding process. Therefore, this embodiment improves the mold itself in order to achieve the purpose of automatic exhaust. To this end, this embodiment provides a method for exhausting heat during the thermosetting molding process.

[0033] The method for exhausting the thermosetting molding process provided by this embodiment first opens the exhaust hole 2 on the mold wall of the mold 1, specifically, opens the exhaust hole 2 at the center of the wall thickness of the mold 1 or at a position upward from the center. Hole 2, opening vent hole 2 at this position is mainly to ensure the stability of the overall structure of the mold 1, and uniformly process the deep gap 3 on the inner surface of the mold 1. The width of the deep gap 3 is bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com