Method for high-efficiency nitrosation of high-concentration ammonia-nitrogen wastewater with sodium carbonate for providing alkalinity

A technology of ammonia nitrogen wastewater and sodium carbonate, which is applied in the direction of chemical instruments and methods, water pollutants, biological water/sewage treatment, etc., to achieve the effect of cost saving and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

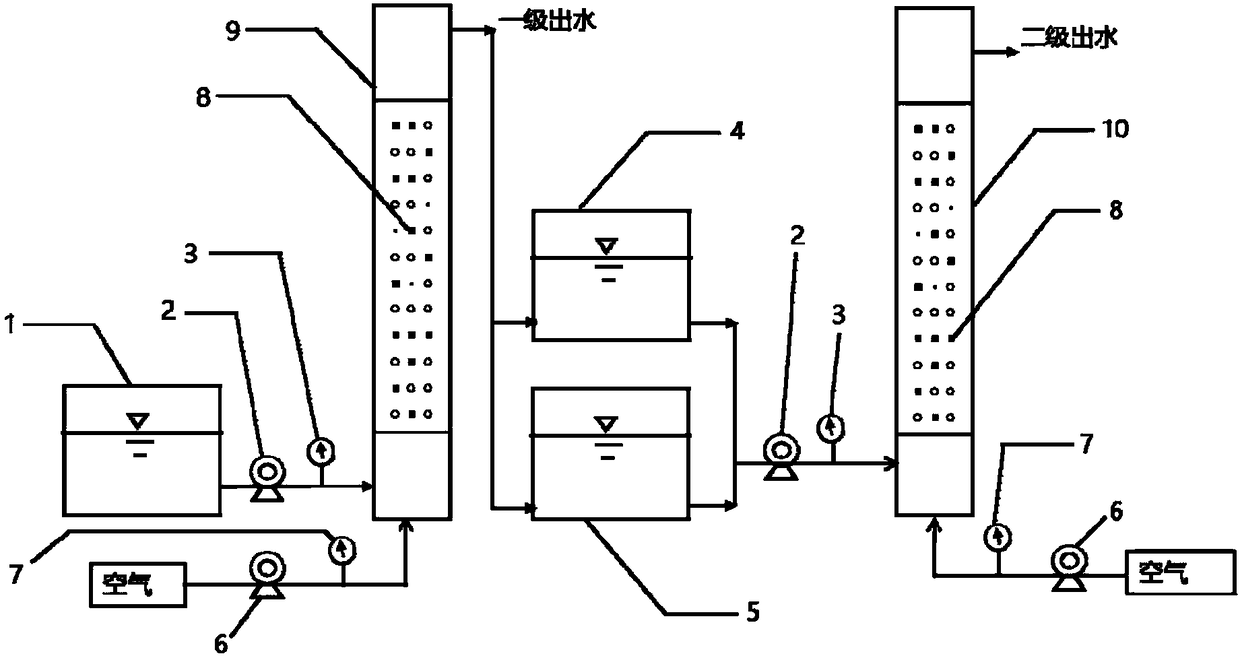

[0039] A method for providing alkalinity with sodium carbonate to realize high-efficiency nitrification of high-concentration ammonia nitrogen wastewater, comprising the following steps:

[0040] (1) The film-hanging domestication method of two biofilm reactors:

[0041] ① Adsorption of ammonia nitrogen by filler: add natural zeolite with a particle size of 0.5-2 mm to two biofilm reactors respectively, add sodium carbonate as alkalinity according to alkalinity: ammonia nitrogen = 4:1 (alkalinity is calculated as calcium carbonate), and continuously Influent, the concentration of ammonia nitrogen in the influent is 250mg / L, the residence time is 8h, the dissolved oxygen in the reactor is controlled at 0.1-7.0mg / L, and the temperature is 20-40°C; until the concentration of ammonia nitrogen in the effluent is about 150mg / L, this step is completed ;

[0042] ②Packing film on filler: After completing ①, add aerobic nitrification sludge, the ratio of the mass of sludge added to th...

Embodiment 2

[0045] A method for providing alkalinity with sodium carbonate to realize high-efficiency nitrification of high-concentration ammonia nitrogen wastewater, comprising the following steps:

[0046] (1) the start of two biofilm reactors is the same as Example 1;

[0047] (2) the ammonia nitrogen concentration of ammonia nitrogen wastewater in the water storage device is 600mg / L, by alkalinity: ammonia nitrogen=4:1 (alkalinity is calculated in calcium carbonate) to calculate sodium carbonate dosage, carry out partial nitrosation; The sodium is divided into two equal parts, that is, the first part of sodium carbonate and the second part of sodium carbonate; the first part of sodium carbonate is added to the water storage device, and the first part of sodium carbonate is mixed evenly with the ammonia nitrogen waste water in the water storage device to obtain the added Ammonia nitrogen wastewater added with sodium carbonate; then the ammonia nitrogen wastewater added with sodium carb...

Embodiment 3

[0049] A method for providing alkalinity with sodium carbonate to realize high-efficiency nitrification of high-concentration ammonia nitrogen wastewater, comprising the following steps:

[0050] (1) The making of two biofilm reactors and the cultivation of the biofilm were the same as in Example 1.

[0051](2) the ammonia nitrogen concentration of ammonia nitrogen wastewater in the water storage device is 800mg / L, by alkalinity: ammonia nitrogen=4:1 (alkalinity is calculated in calcium carbonate) to calculate sodium carbonate dosage, carry out partial nitrosation; The sodium is divided into two equal parts, that is, the first part of sodium carbonate and the second part of sodium carbonate; the first part of sodium carbonate is added to the water storage device, and the first part of sodium carbonate is mixed evenly with the ammonia nitrogen waste water in the water storage device to obtain the added Ammonia nitrogen wastewater added with sodium carbonate; then the ammonia ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com