Low temperature and weather resistant HIPS/PE (High Impact Polystyrene/Polyethylene) alloy material for making plastic board and preparation method of low temperature and weather resistant HIPS/PE alloy material

An alloy material and low-temperature-resistant technology, which is applied in the field of low-temperature and weather-resistant HIPS/PE alloy materials and its preparation, can solve the problems of high cost of plastic pallets, failure to form an industrial chain, and unsound pallet standards, and achieve good results. Performance Usable temperature range, improved usability, and high fluidity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

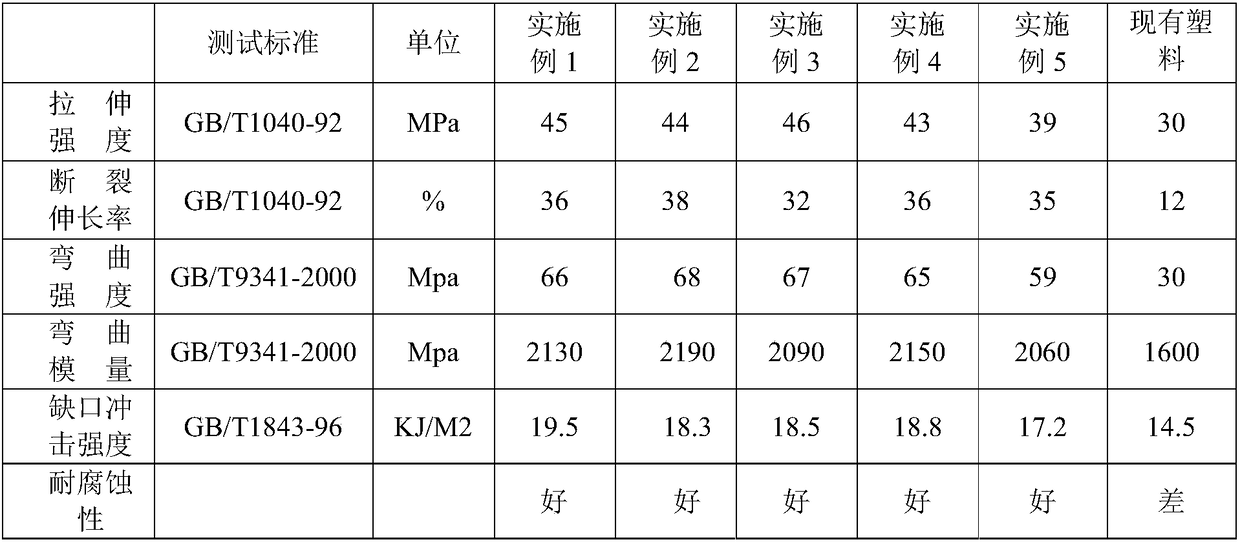

Examples

Embodiment 1

[0031] The preparation of the low-temperature and weather-resistant HIPS / PE alloy material for making plastic pallets includes the following steps:

[0032] (1) Weigh by weight: 52 parts of HIPS, 18 parts of PE, 15 parts of toughening agent, 10 parts of hollow glass microspheres, 0.5 part of ultraviolet absorber, 0.2 part of antioxidant, 2 parts of lubricant and 2.5 parts of color mother;

[0033] (2) Put the components into a high-speed mixer and mix for 15 to 30 minutes to obtain a uniform mixture;

[0034] (3) Melting, extruding and granulating the mixture through a three-stage tandem single-screw extruder to obtain the low-temperature and weather-resistant HIPS / PE alloy material granules used for making plastic pallets in Example 1.

Embodiment 2

[0036] The preparation of the low-temperature and weather-resistant HIPS / PE alloy material for making plastic pallets includes the following steps:

[0037] 1) Weigh by weight: 58 parts of HIPS, 15 parts of PE, 13 parts of toughening agent, 9 parts of hollow glass microspheres, 0.6 part of ultraviolet absorber, 0.2 part of antioxidant, 1.5 parts of lubricant and 2.7 parts of masterbatch ;

[0038] (2) Put the components into a high-speed mixer and mix for 15 to 30 minutes to obtain a uniform mixture;

[0039] (3) Melting, extruding and granulating the mixture through a three-stage tandem single-screw extruder to obtain the low-temperature and weather-resistant HIPS / PE alloy material granules used for making plastic pallets in Example 2.

Embodiment 3

[0041] The preparation of the low-temperature and weather-resistant HIPS / PE alloy material for making plastic pallets includes the following steps:

[0042] 1) Weigh by weight: 64 parts of HIPS, 13 parts of PE, 10 parts of toughening agent, 8 parts of hollow glass microspheres, 0.2 part of ultraviolet absorber, 0.1 part of antioxidant, 1.7 parts of lubricant and 3 parts of color masterbatch ;

[0043] (2) Put the components into a high-speed mixer and mix for 15 to 30 minutes to obtain a uniform mixture;

[0044] (3) Melting, extruding and granulating the mixture through a three-stage tandem single-screw extruder to obtain the low-temperature and weather-resistant HIPS / PE alloy material granules used for making plastic pallets in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com