High-torque and high-fatigue-resistance threaded joint

A threaded joint and high-torque technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of internal thread expansion of threaded joints, low torsional strength of threaded joints, thread fracture of external threaded joints, etc., to achieve increased Firmness, reduction of damage probability and duration, effects of stress level reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

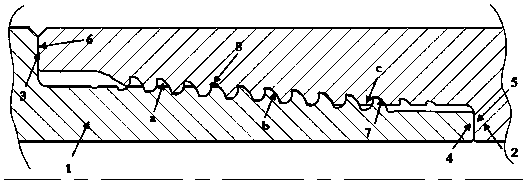

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] see figure 1 , the invention discloses a threaded joint with high torque and high fatigue resistance, comprising an external threaded joint with an external shoulder of an external thread, an external thread section and an external end surface of an external thread, and an internal end surface with an internal thread, an internal thread section and an internal thread The internal thread joint of the external shoulder; it is characterized in that: the external thread section and the internal thread section form a contact surface between the two after they are completely screwed, and the contact surface forms an incomplete thread engagement section at the front section and a complete thread engagement section at the middle section The incomplete thread meshing segment of the segment and the rear segment, the thread teeth in the area of the three segments have di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com