An integrated structure of mems piezoelectric printing nozzle assembly

A printing nozzle and piezoelectric technology, applied in printing and other directions, can solve the problems of affecting the life of CMOS circuits, affecting the performance of CMOS circuits, and being uneconomical, and achieve the effects of reducing Joule heat consumption, reducing size, and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

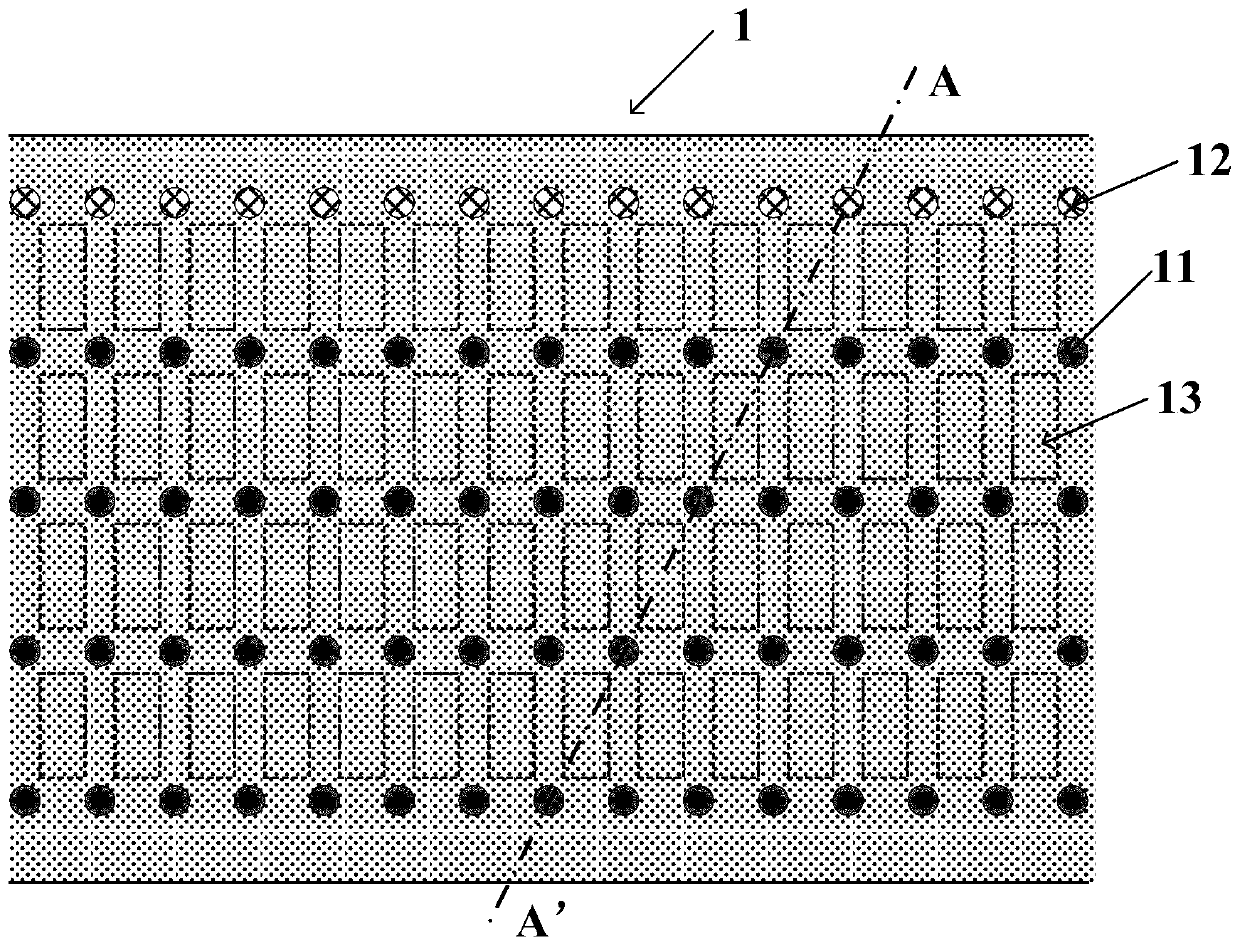

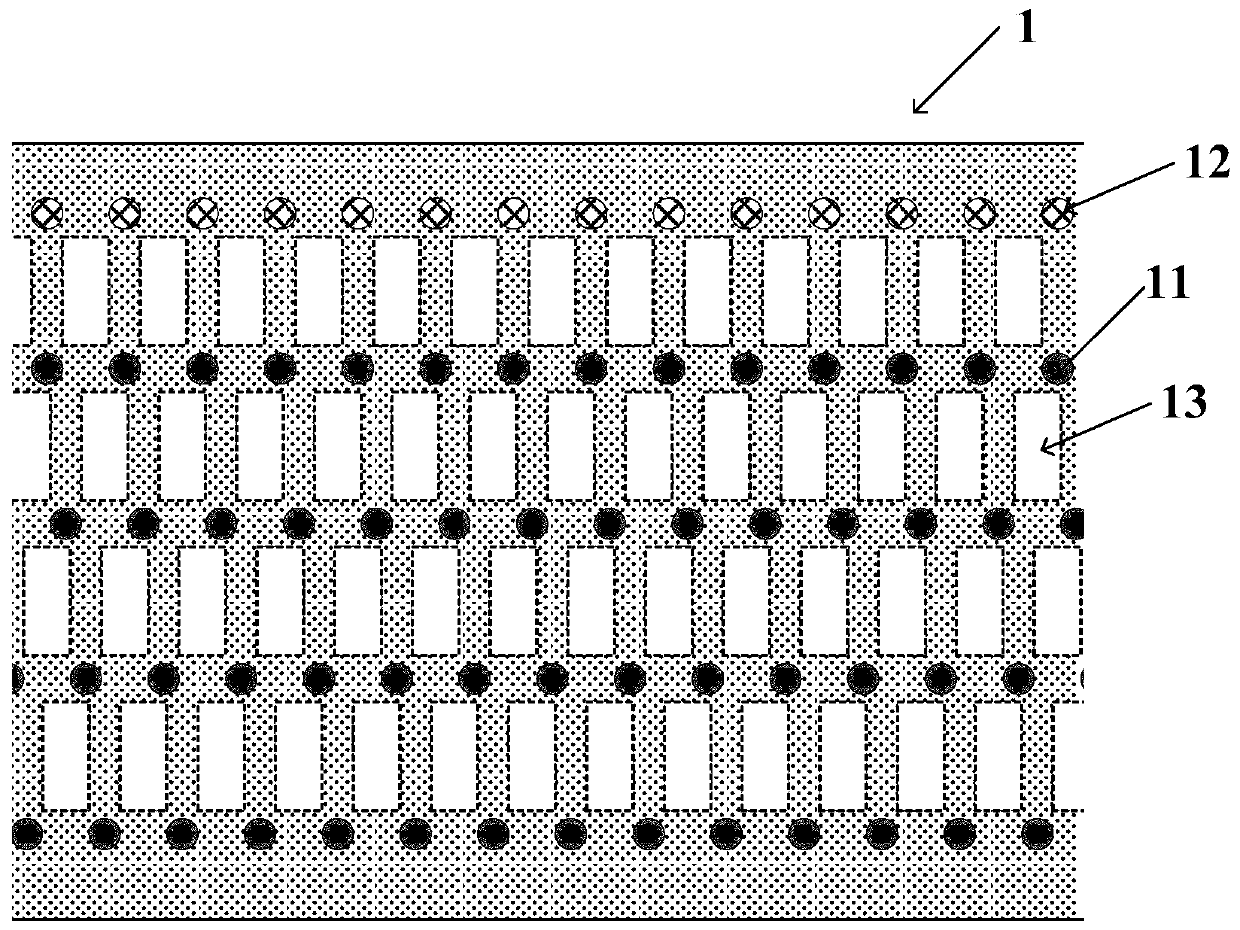

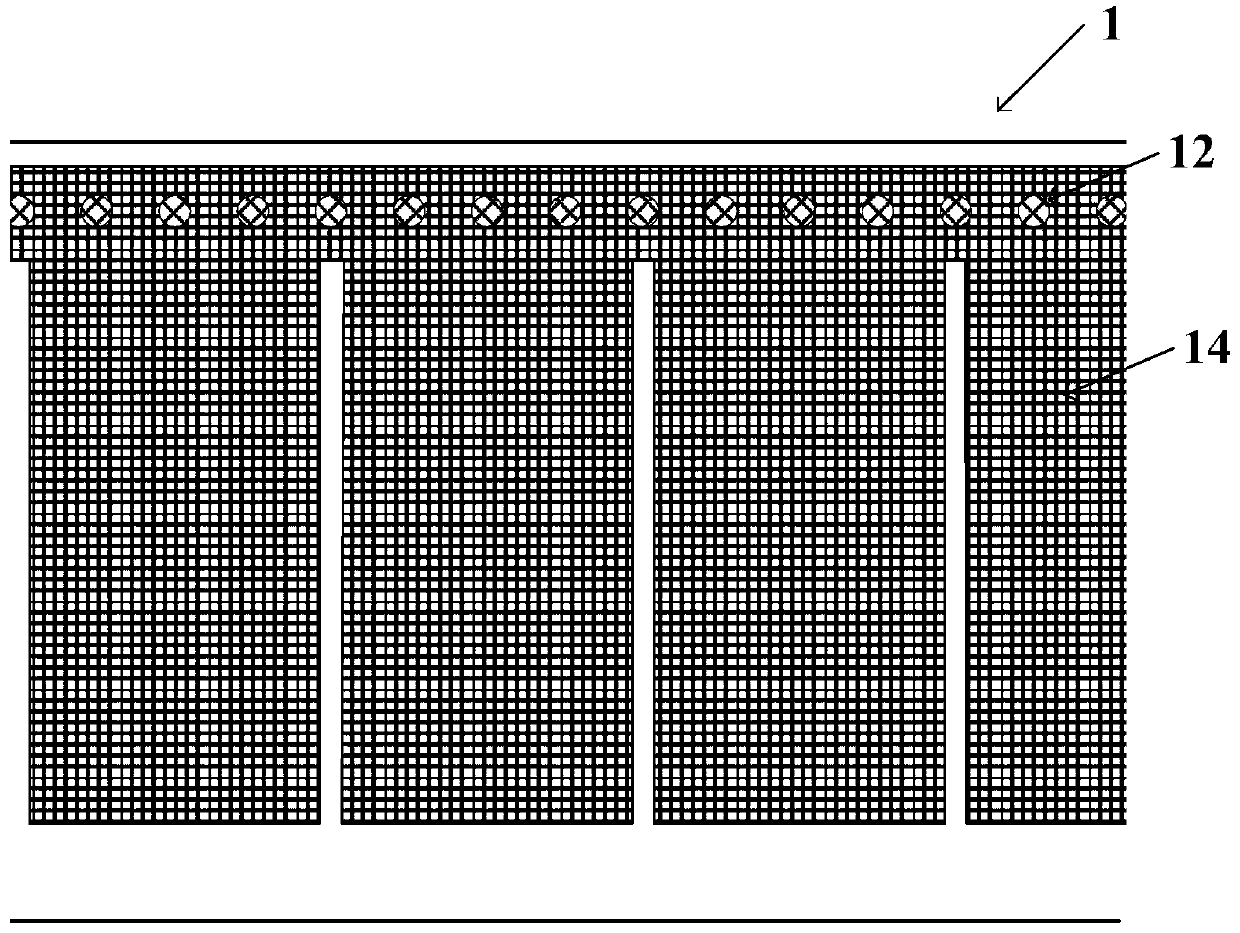

[0068] Nozzle density is an important technical indicator of inkjet print head, the higher the nozzle density, the higher the resolution of the print head. Due to the limitation of the minimum pitch of nozzles, the density of a single row of nozzles is very limited, and the use of multiple rows of nozzles to form a nozzle array is an effective means to increase the density of nozzles. The MEMS piezoelectric print head chip of the nozzle array is narrow and long, with a width of about 1 cm and a length of 7 to 10 cm. Due to the large aspect ratio, only a part of the MEMS piezoelectric print head chip (component) along the length direction is shown in the figure.

[0069] figure 1 An example of a schematic plan view of a nozzle array composed of 4 rows of nozzles is given in , where there is no misalignment among the rows of 4 nozzles. For brevity, figure 1 Only the array arrangement of the corresponding ink chambers 13 is drawn in the figure. Normally, the nozzles 17 are des...

Embodiment 2

[0096] see Figure 15 , Flip-chip the drive / control integrated circuit chip 23 on the package substrate 26, and set the underfill material 25; then through the solder ball 27, realize the electrical connection with the silicon transfer substrate 2, thereby realizing the MEMS piezoelectricity with the nozzle array The electrical connection of the print head chip 1. The silicon transfer substrate 2 and the driving / control integrated circuit chip 23 are flip-chip mounted on the same surface of the package substrate 26 , and the silicon transfer substrate 2 is located above the driving / control integrated circuit chip 23 . The solder balls 27 are distributed around the silicon interposer substrate 2 avoiding the area of the driving / control integrated circuit chip 23 . The height of the solder ball 27 is greater than the sum of the thickness of the driving / control integrated circuit chip 23 and the height of the bump 24 . An underfill material 25 is applied between the driving / c...

Embodiment 3

[0099] The speed of each I / O pin of the driving / control integrated circuit chip 23 is not high, and the wire bonding can also meet the current capacity, DC voltage drop and signal integrity of each I / O pin of the driving / control integrated circuit chip 23 To meet the requirements of safety, wire bonding can be used instead of flip-chip bump bonding in Embodiment 2 to realize the micro-assembly of the driving / control integrated circuit chip 23 on the packaging substrate 26, so as to further reduce the difficulty of micro-assembly. Simultaneously, because the driving / control integrated circuit chip 23 is directly mounted on the packaging substrate 26, the thermal resistance between the driving / control integrated circuit chip 23 and the packaging substrate 26 is smaller than that of embodiment two, so the driving / control integrated circuit chip 23 is dissipated. Effect is better than embodiment two. For the structural schematic diagram of the third embodiment of the MEMS piezoele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com