LED light source for LED lamp and manufacturing method

A technology of LED light source and LED lamp, applied in the field of LED light source, can solve the problems of increasing the difficulty of thinning the display and increasing the manufacturing cost of the display, and achieve the effects of rapid heat dissipation, easy large-scale manufacturing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

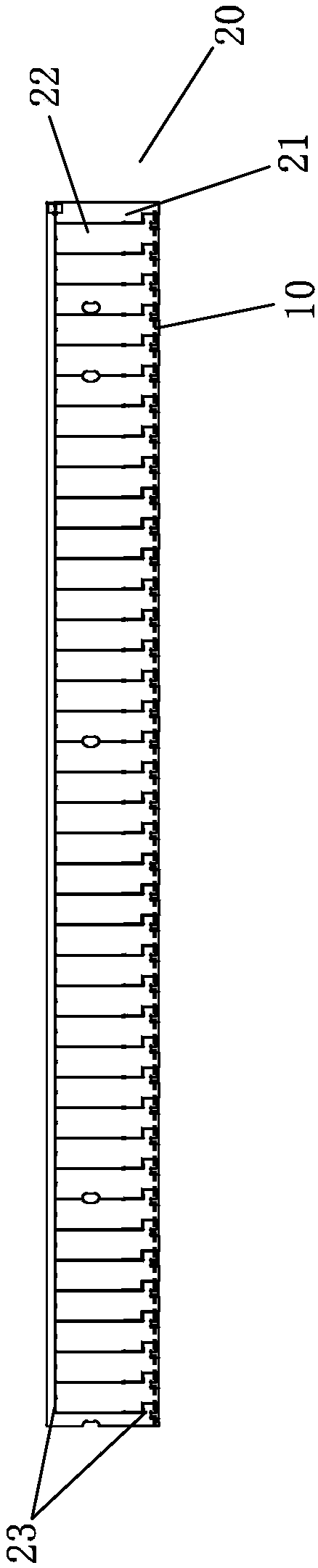

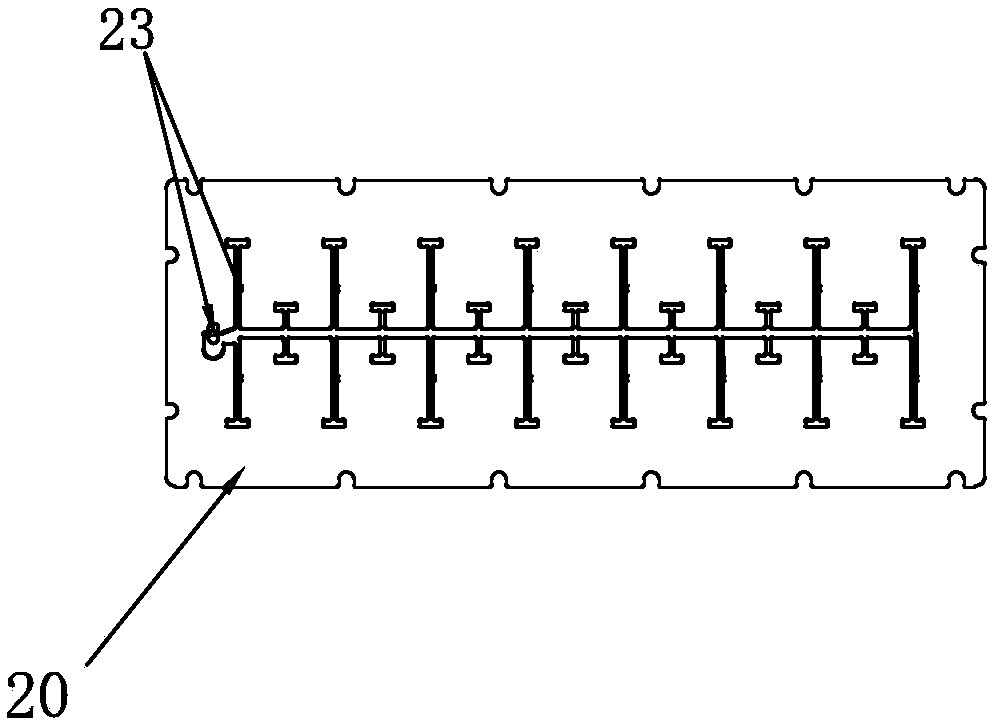

[0132] Refer to the attached Figure 1 to Figure 6 and Figure 9 to Figure 14As shown, the LED light source according to the preferred embodiment of the present invention is clarified, which can be used as a side-entry LED light source for a display, a light box or a light source for an LED lamp, etc., wherein the LED light source includes a group of LED illuminants 10, a The conductive heat dissipation plate 20 and an insulating heat dissipation layer 30 , wherein the conductive heat dissipation plate has two side surfaces 201 , wherein the LED illuminant 10 and the insulating heat dissipation layer 30 are both arranged on the same side surface 201 of the conductive heat dissipation plate. Preferably, the insulating heat dissipation layer 30 is arranged on both sides (sides 201 ) of the conductive heat dissipation plate 20 , so that both sides of the conductive heat dissipation plate 20 of the LED light source can be used to conduct heat to the insulating heat dissipation lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com