Device and method for measuring residual stress on surface of work piece based on laser ultrasonic

A residual stress and workpiece surface technology, applied in measuring devices, force/torque/work measuring instruments, measuring force, etc., can solve the problems of complicated and expensive equipment, damage to workpieces, slow detection speed, etc., to achieve convenient use, low cost, Detecting slow effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

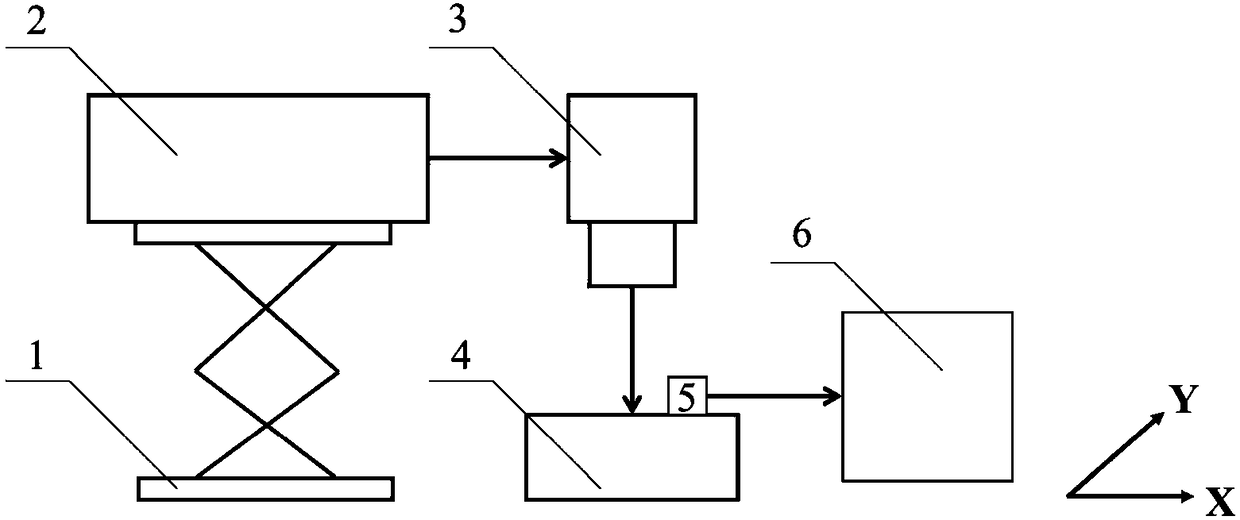

[0034] The embodiment of the present invention relates to a laser ultrasonic-based workpiece surface residual stress measurement device and its method. In this method, the pulsed laser focused into a point source is scanned by a vibrating mirror to generate surface waves on the surface of the workpiece, and the surface waves are detected by a piezoelectric sensor. The signal is received and calculated, so as to realize the detection of the residual stress on the surface of the workpiece.

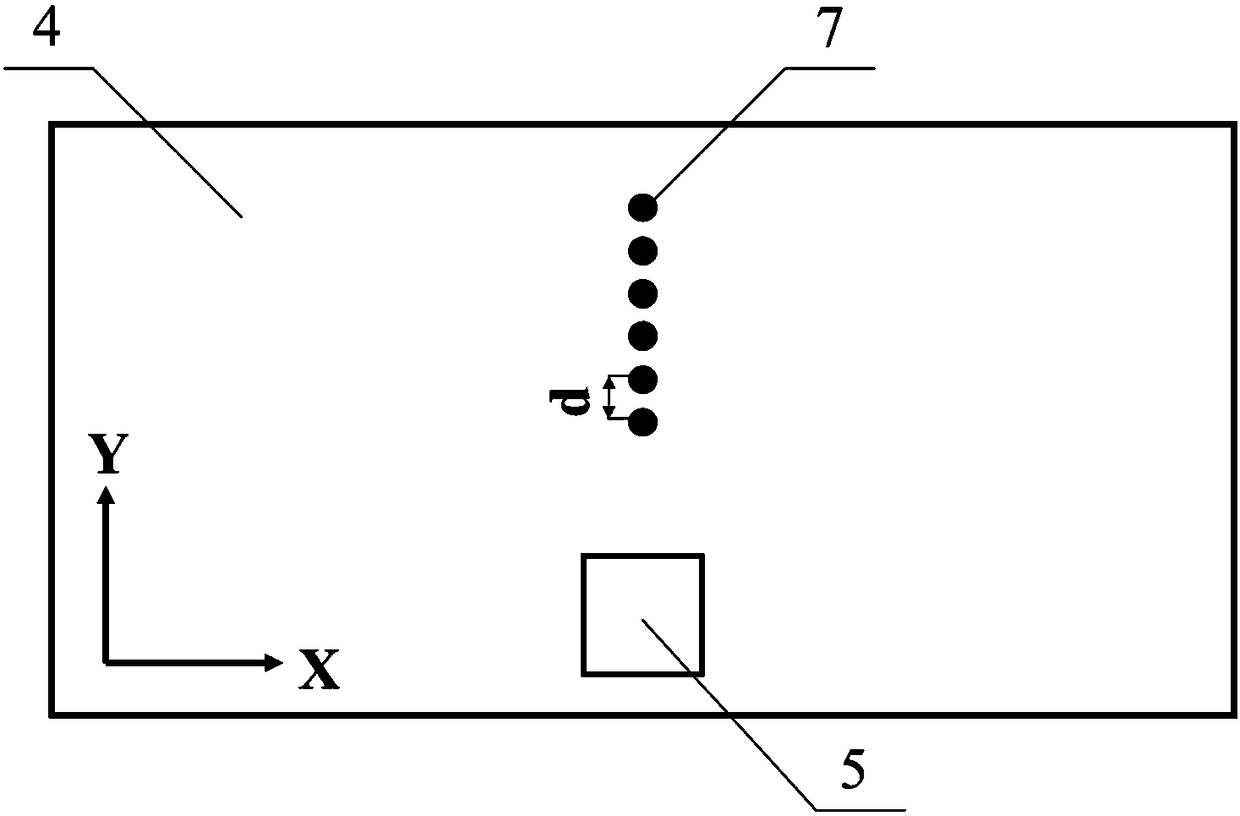

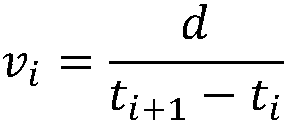

[0035] Such as figure 1 Shown, the measuring device that adopts among the present invention includes: pulsed laser 2, vibrating mirror 3, piezoelectric sensor 5 and oscilloscope 6; Wherein pulsed laser 2 is used for exciting surface acoustic wave at workpiece (4 surface; Workpiece surface is plane. The piezoelectric sensor 5 is connected to the oscilloscope 6 through the probe lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com