Water flow direction sensor

A sensor and water flow technology, applied in the field of sensors, can solve the problems of large measurement error, high failure rate and complex circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

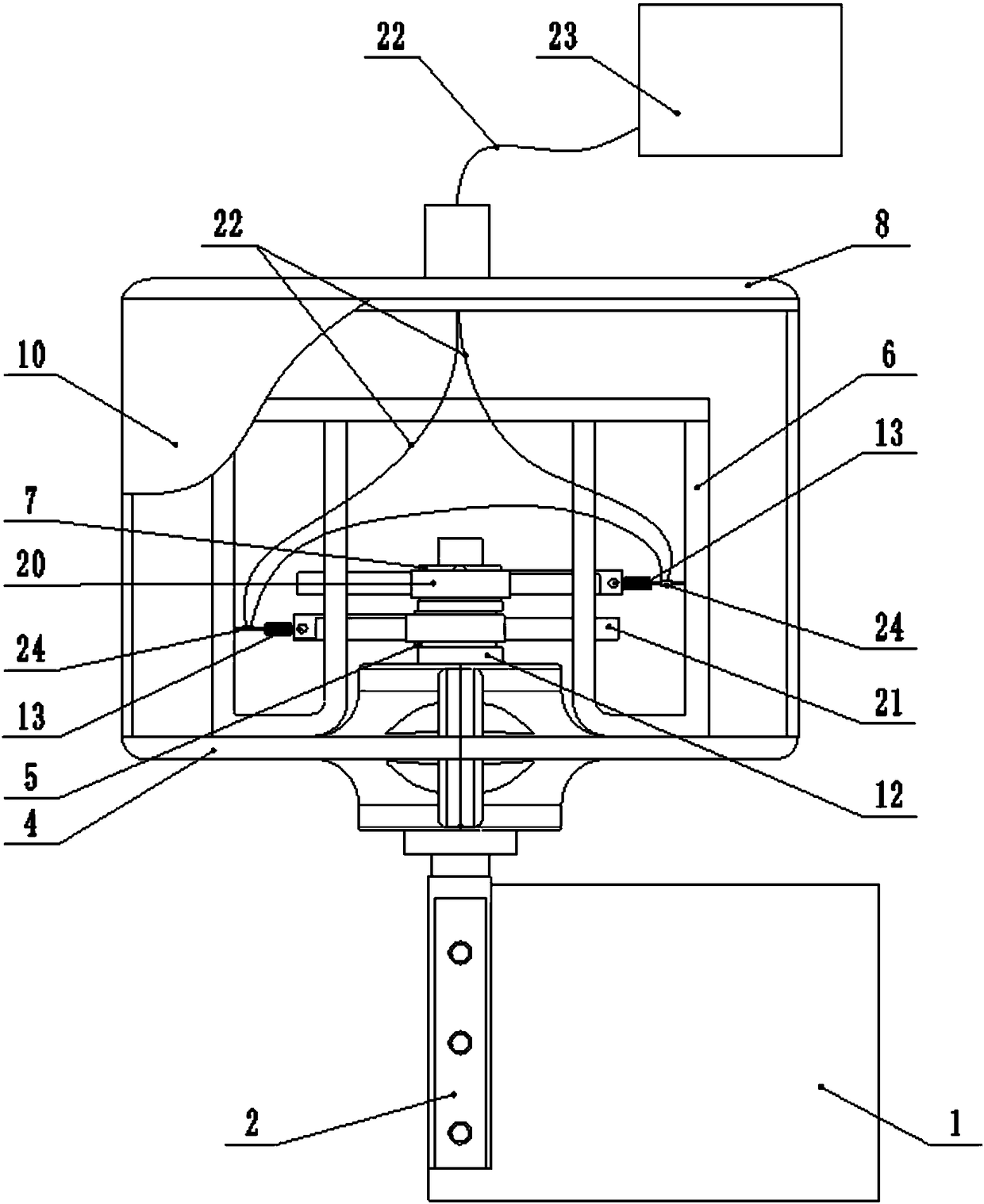

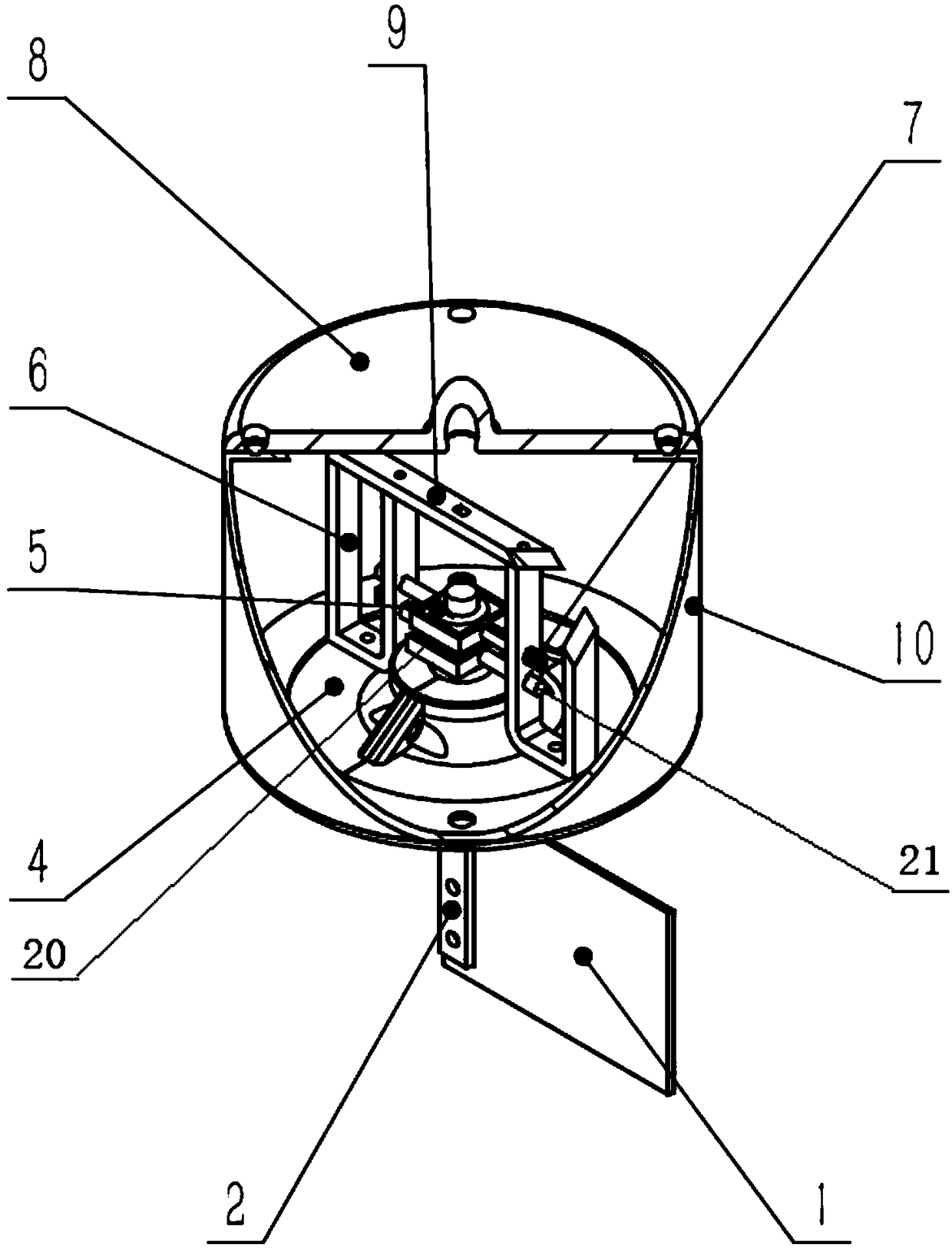

[0031] Further, see figure 1 , 3, as a specific embodiment of the water flow direction sensor provided by the present invention, the first cam 5 and the second cam 7 are arranged in a rectangular frame 20, and guide shafts 21 are respectively provided at both ends of the rectangular frame 20; Both the first column 14 and the second column 15 include an outer column 17 for connecting with the strain spring and an inner column 16 for cooperating with the guide shaft 21, and the inner column 16 is provided with a The guide hole that the guide shaft 21 cooperates; the left guide shaft 21 of the first cam 5 passes through the inner support 16 and is connected with the strain spring, and the right guide shaft 21 of the second cam 7 passes through the inner support 16 and connects with the strain spring. The strain springs are connected. The first cam and the second cam are limited by the rectangular frame, and at the same time, the guide shafts on both sides of the rectangular fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com