A high-precision and high-stability mirror adjustment device based on flexible hinges

A flexible hinge and adjustment device technology, applied in installation, instrumentation, optics, etc., can solve the problems of inability to perform on-orbit correction, poor mechanical environment resistance, large volume and weight of the mechanism, and achieve simple adjustment control process and structural design. , The effect of meeting the requirements of high reliability and small driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

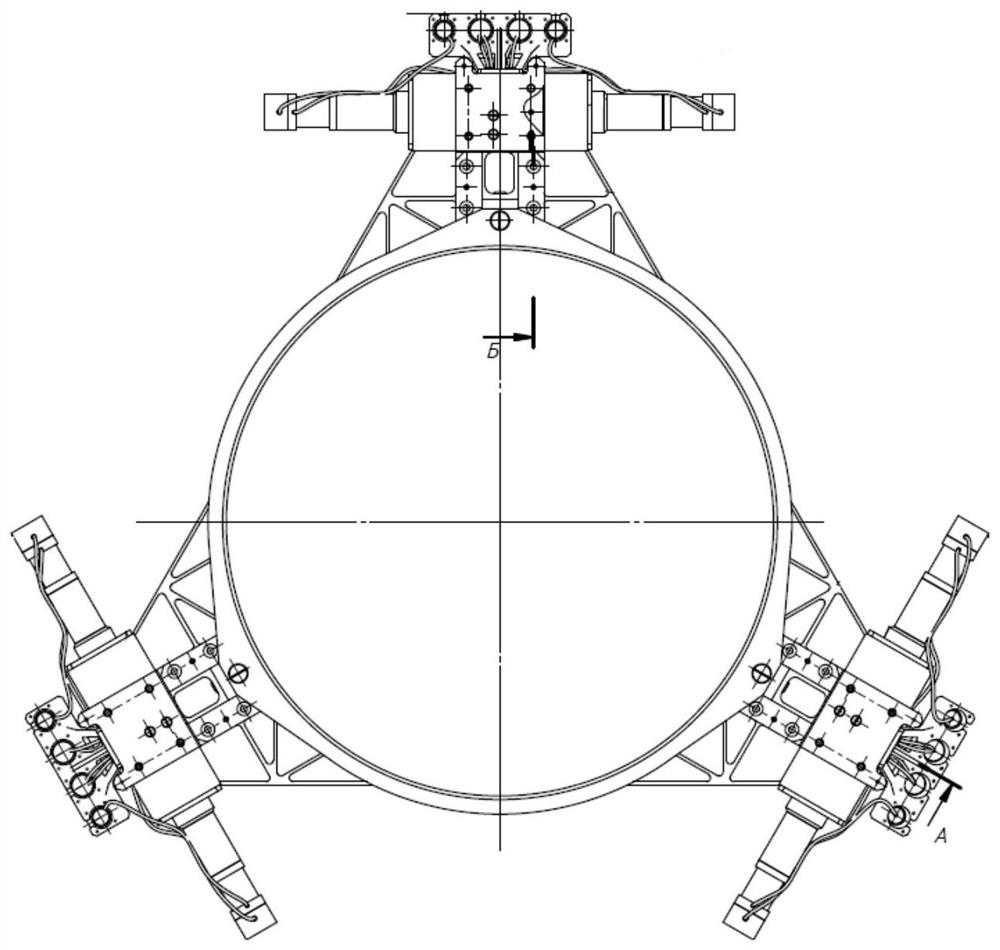

[0024] A high-precision, high-stable mirror adjustment device based on flexible hinges, including at least three flexible support mechanisms, preferably three flexible support mechanisms, and the three are distributed at an angle of 120°, such as image 3 shown.

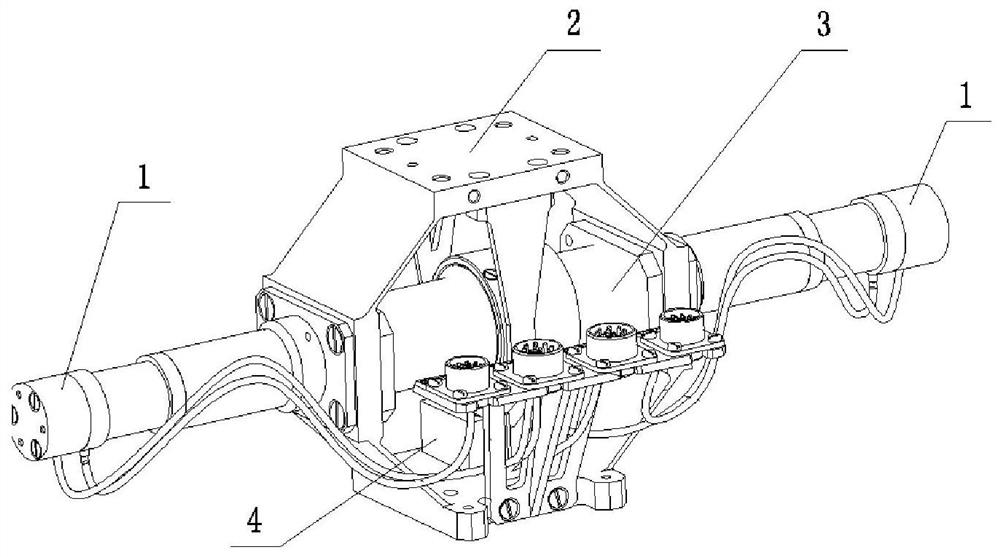

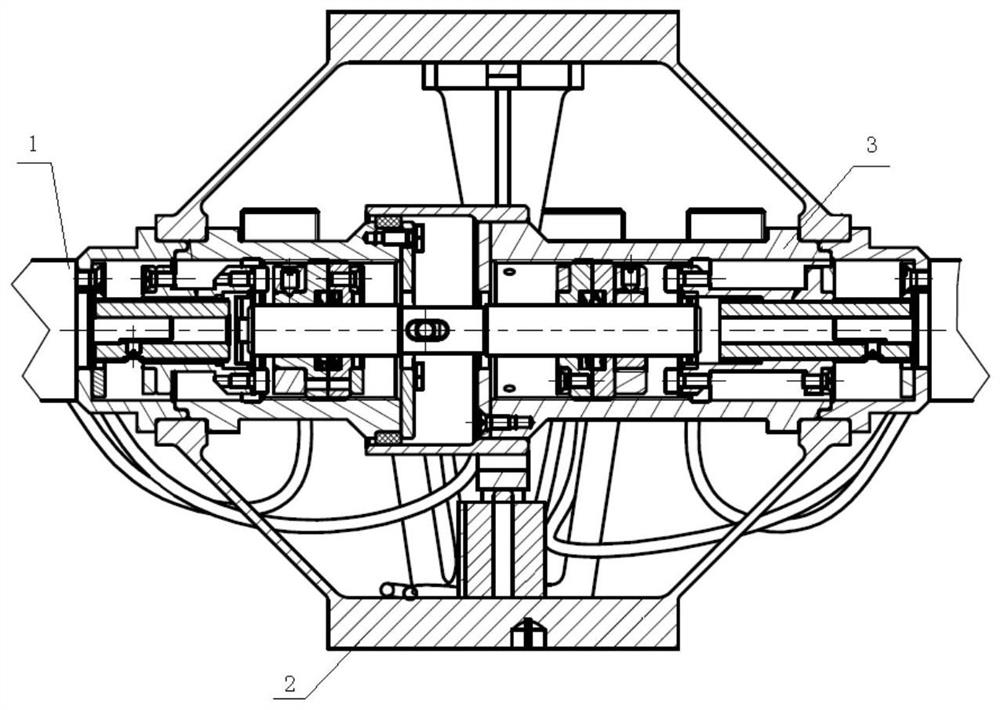

[0025] The flexible support mechanism has the same structure, including motor 1, flexible hinge 2, differential screw reducer 3 and displacement sensor 4, such as figure 1 , figure 2 As shown, both ends of the shaft are coaxially connected with a motor 1, and the connection between the motor 1 and the shell of the differential thread reducer 3 is fixedly connected with the flexible hinge 2, and the shells of the differential thread reducer 3 can slide relative to each other.

[0026] The shape of the flexible hinge 2 is an octagonal structure, and the four surfaces in the orthogonal direction are non-def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com