Simulation testing method and system for hydraulic support controller software

A technology of hydraulic support and simulation testing, which is applied in software testing/debugging, instrumentation, error detection/correction, etc. It can solve the problems of affecting test judgment results, occupying hardware resources, and incomplete coverage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

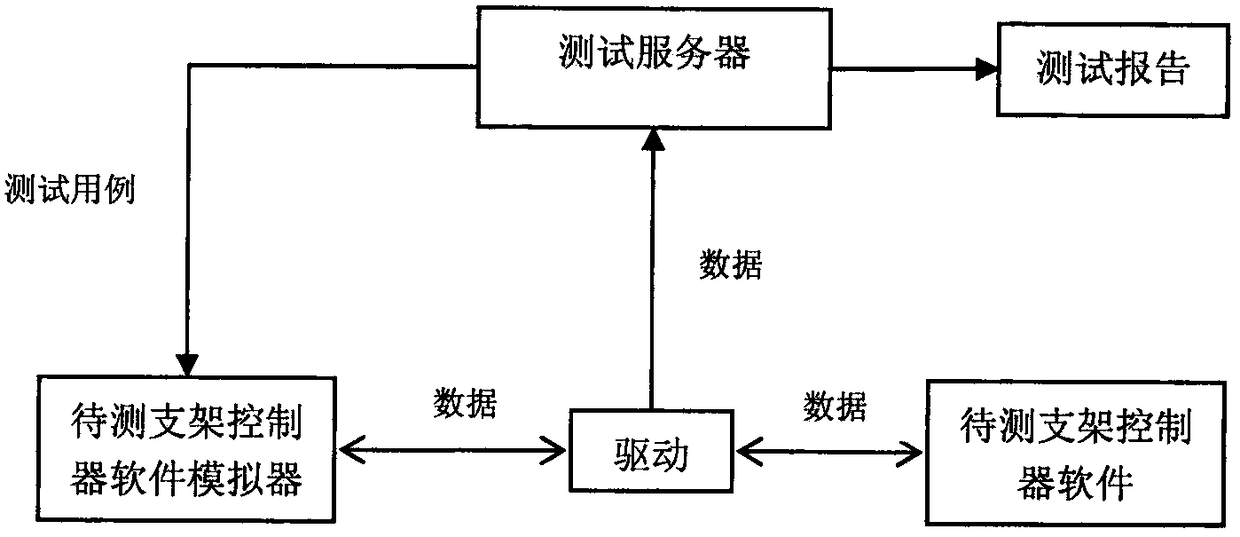

[0034] figure 2 A schematic block diagram showing a hydraulic support controller software simulation test system according to an embodiment of the present invention;

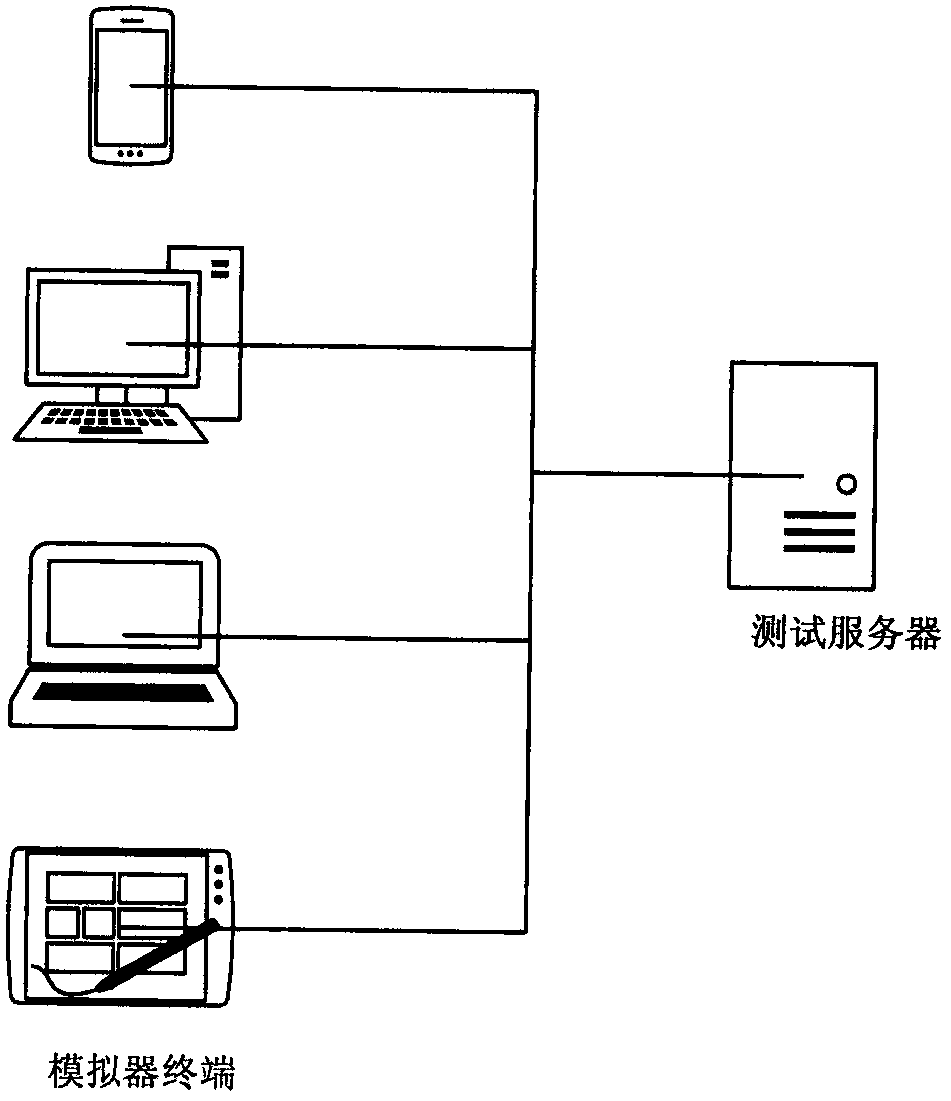

[0035] image 3 A schematic block diagram of a hardware network of a hydraulic support controller software simulation test system according to an embodiment of the present invention is shown.

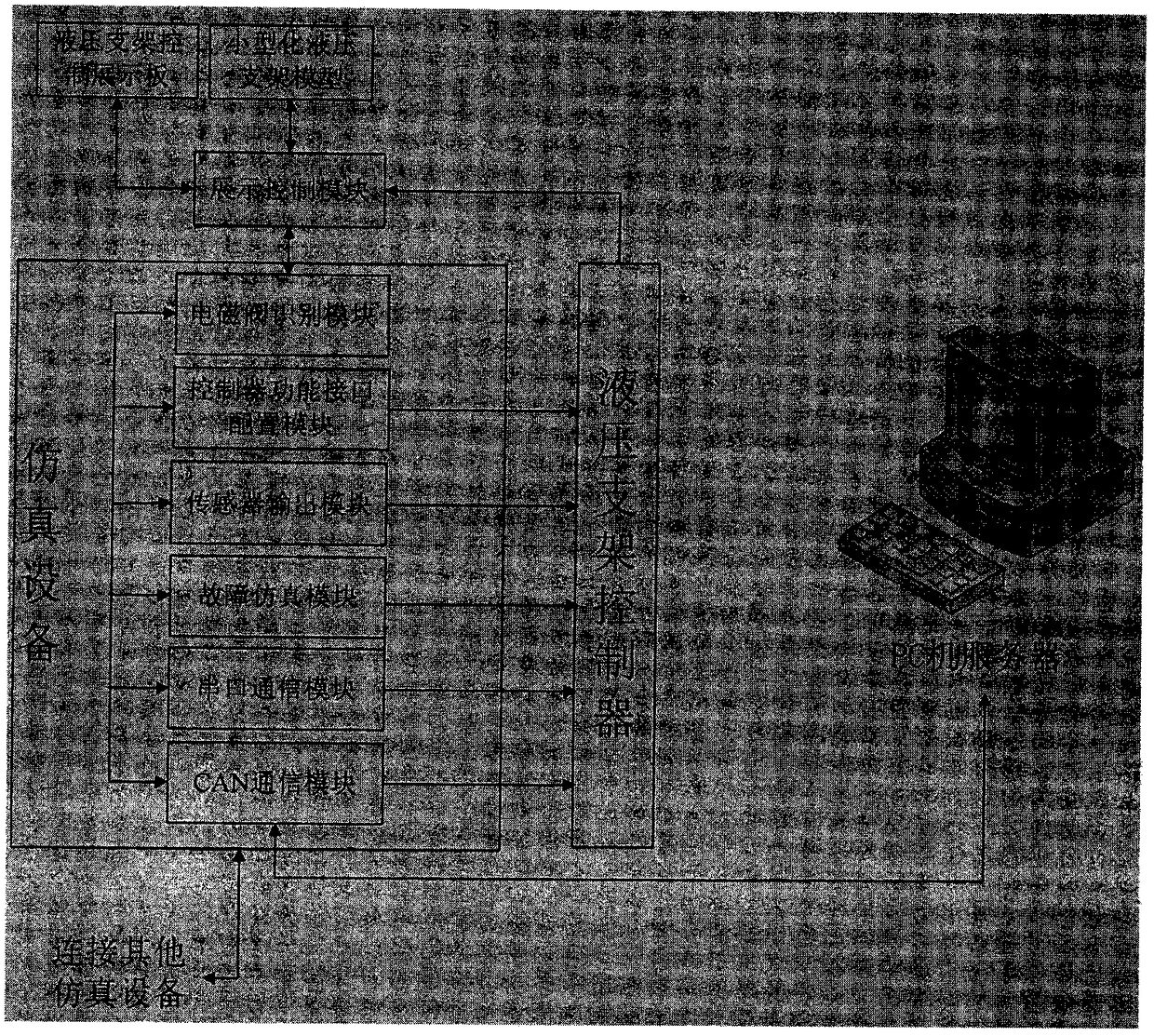

[0036] Such as figure 2 , image 3 As shown, the hydraulic support controller software simulation test system according to an embodiment of the present invention is characterized in that it includes:

[0037] The test server includes: a test case generation module, a task scheduling module, a result verification module, and a first communication module;

[0038] A hydraulic support controller simulator, including: an environment simulation module, a control command generation module, a peripheral drive module, a second communication module and a hydraulic support controller software data interface;

[0039] Wherein...

Embodiment 2

[0048] Such as Figure 4 The shown flow chart of the hydraulic support controller software simulation test method,

[0049] Another embodiment of the present invention provides a simulation test method of hydraulic support controller software, comprising:

[0050] Generate test cases according to the scenarios to be tested;

[0051] Send the test case to the hydraulic support controller simulator;

[0052] The hydraulic support controller simulator generates software input data according to the test case, and sends it to the hydraulic support controller software to be tested through a data interface;

[0053] Acquiring the driving data generated by the hydraulic support controller software according to the software input data;

[0054] comparing the driving data with the expected result of the test case to generate a test result.

[0055] Among them, in the step of generating test cases according to the scene to be tested, the data of the test cases can come from the real ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com