Pre-embedded thread sleeve of wind turbine blade

A wind power blade and pre-embedded technology, which is applied to wind power generation, wind engines consistent with the wind direction, wind engines, etc., can solve the problems of limited processing conditions and cost of the screw sleeve length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples.

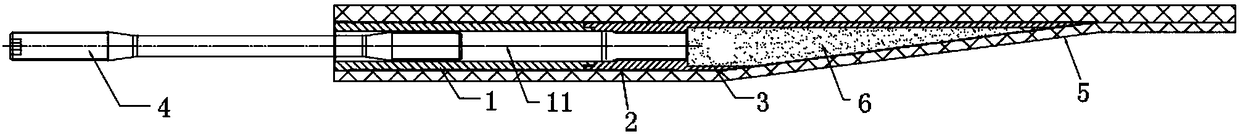

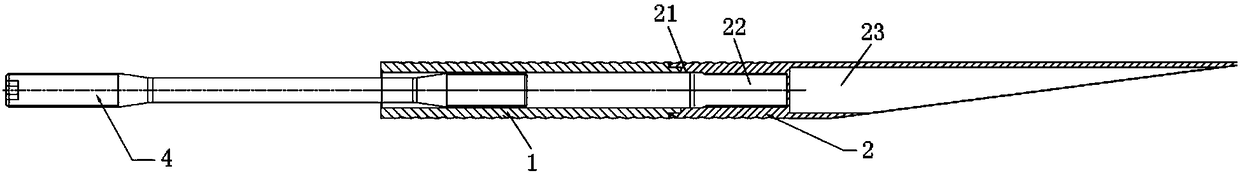

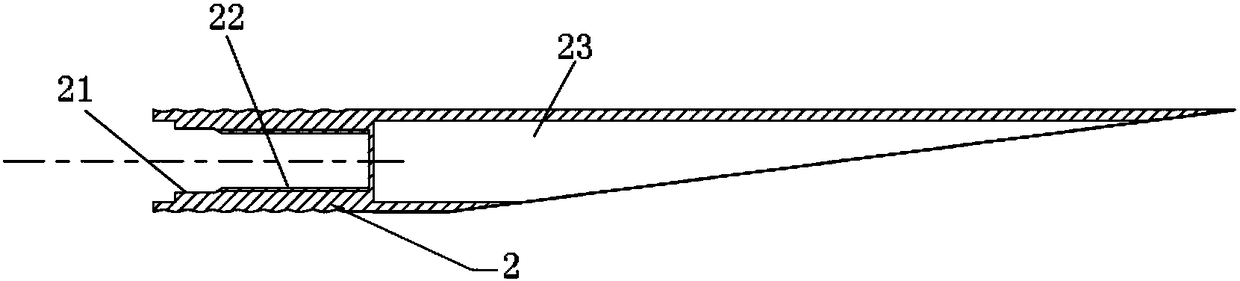

[0019] Such as Figure 1 to Figure 5 As shown, the wind turbine blade embedded screw sleeve provided in this embodiment includes a first sleeve 1, a second sleeve 2 and a wedge-shaped pipe 3 (made of iron) with a built-in filler 6 (preferably PVC). The first sleeve 1 and the second sleeve 2 are both round sleeves, the material is 42CrMoA, and the surface is treated with internal and external Dacromet / Dlata tone+Dlata seal to prevent corrosion. The first sleeve 1 and the second sleeve Cylinder 2 adopts interference fit and is forcibly connected by hydraulic pressure to form a whole in advance, which can solve the problem of too long sleeve length and high processing cost, because the sleeve is too long and requires a long drill bit, which has the problem of vibration The processing accuracy is low, and the input cost of the drilling machine is high. Dividing the sleeve into tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com