A method of coating cl-20 explosives with a double-layer insensitivity structure

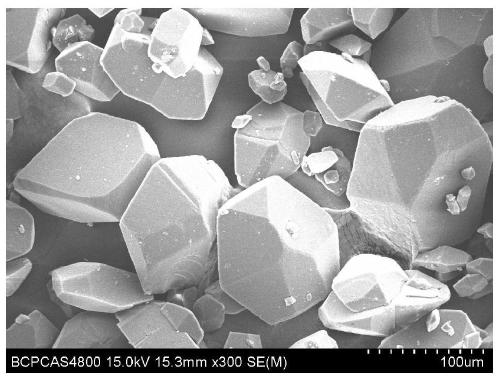

A CL-20, explosive technology, applied in the directions of explosives, explosives processing equipment, non-explosive/non-thermal agent components, etc., can solve the problems of high sensitivity, polygonal crystal shape, limited application, etc., and achieves simple steps, easy to control, reduce The effect of mechanical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

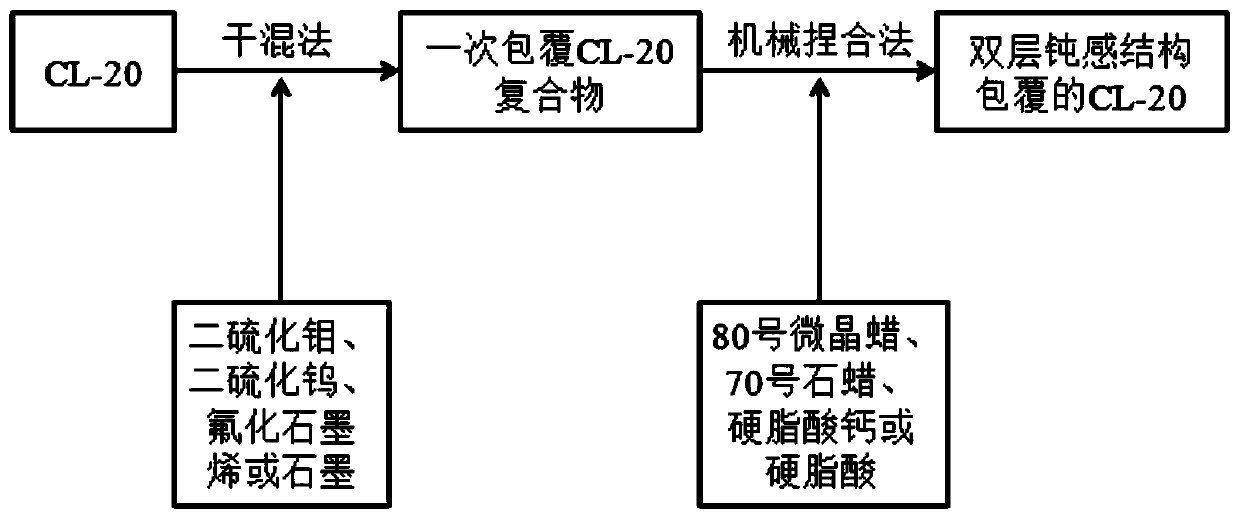

[0026] According to a preferred embodiment of the present invention, the method for coating CL-20 explosives with a double-layer insensitivity structure includes:

[0027] 1) Coating the first desensitizing agent with a layered structure and low friction coefficient on the surface of CL-20 by dry mixing method to prepare a primary coated CL-20 explosive compound;

[0028] 2) Dissolving the second desensitizing agent with high specific heat capacity and low melting point in a solvent to prepare a second desensitizing agent solution with a mass concentration of 5% to 15%;

[0029] 3) Add the second desensitizing agent solution into the kneader, then add the primary coated CL-20 explosive compound into the kneader, set the kneader speed to 10-15r / min, alternate forward and reverse, and the kneading temperature is 50~60℃, the kneading time is 40~70min, after kneading, turn on the vacuum equipment, the vacuum degree is 0.01~0.04MPa, dry after the solvent evaporates, and then prepar...

Embodiment 1

[0035] This example is used to illustrate the method of the present invention for coating CL-20 explosives with a double-layer insensitivity structure.

[0036] Specifically include the following steps:

[0037] (1) Weigh 1000g of CL-20 and 3g of molybdenum disulfide and place them in a mixer. The rotation speed of the mixer is 6r / min, and the mixing time is 40min. After mixing, a primary coated CL-20 explosive compound is prepared. things.

[0038] (2) 20 g of No. 70 paraffin was dissolved in 300 g of petroleum ether at a dissolution temperature of 50-60° C. to prepare a desensitizing agent solution with a mass concentration of 10% for use.

[0039] (3) Keep the temperature of the kneader jacket at 50-60°C, add the prepared primary coated CL-20 explosive compound into the kneader, then add the insensitivity agent solution, set the kneader speed to 10r / min, front and back Rotation is carried out alternately, the kneading temperature is 50-60°C, and the kneading time is 50 mi...

Embodiment 2

[0042] This example is used to illustrate the method of the present invention for coating CL-20 explosives with a double-layer insensitivity structure.

[0043] Specifically include the following steps:

[0044] (1) Weigh 1000g of CL-20 and 3g of molybdenum disulfide and place them in a mixer. The speed of the mixer is 5r / min, and the mixing time is 40min. After mixing, a primary coated CL-20 explosive compound is prepared. things.

[0045] (2) 20g of calcium stearate is dissolved in 300g of benzene, and the dissolution temperature is 50-60° C. to prepare a desensitizing agent solution with a mass concentration of 10%, which is ready for use.

[0046](3) Keep the temperature of the kneader jacket at 50-60°C, add the prepared primary coated CL-20 explosive compound into the kneader, then add the insensitivity agent solution, set the kneader speed to 10r / min, front and back Rotation is carried out alternately, the kneading temperature is 50-60°C, and the kneading time is 60 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com