Novel square steel tube concrete column and construction method thereof

A technology of concrete columns and construction methods, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of complex design of connection nodes and inconvenient construction, and achieve high engineering application value, strengthen the bonding effect, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

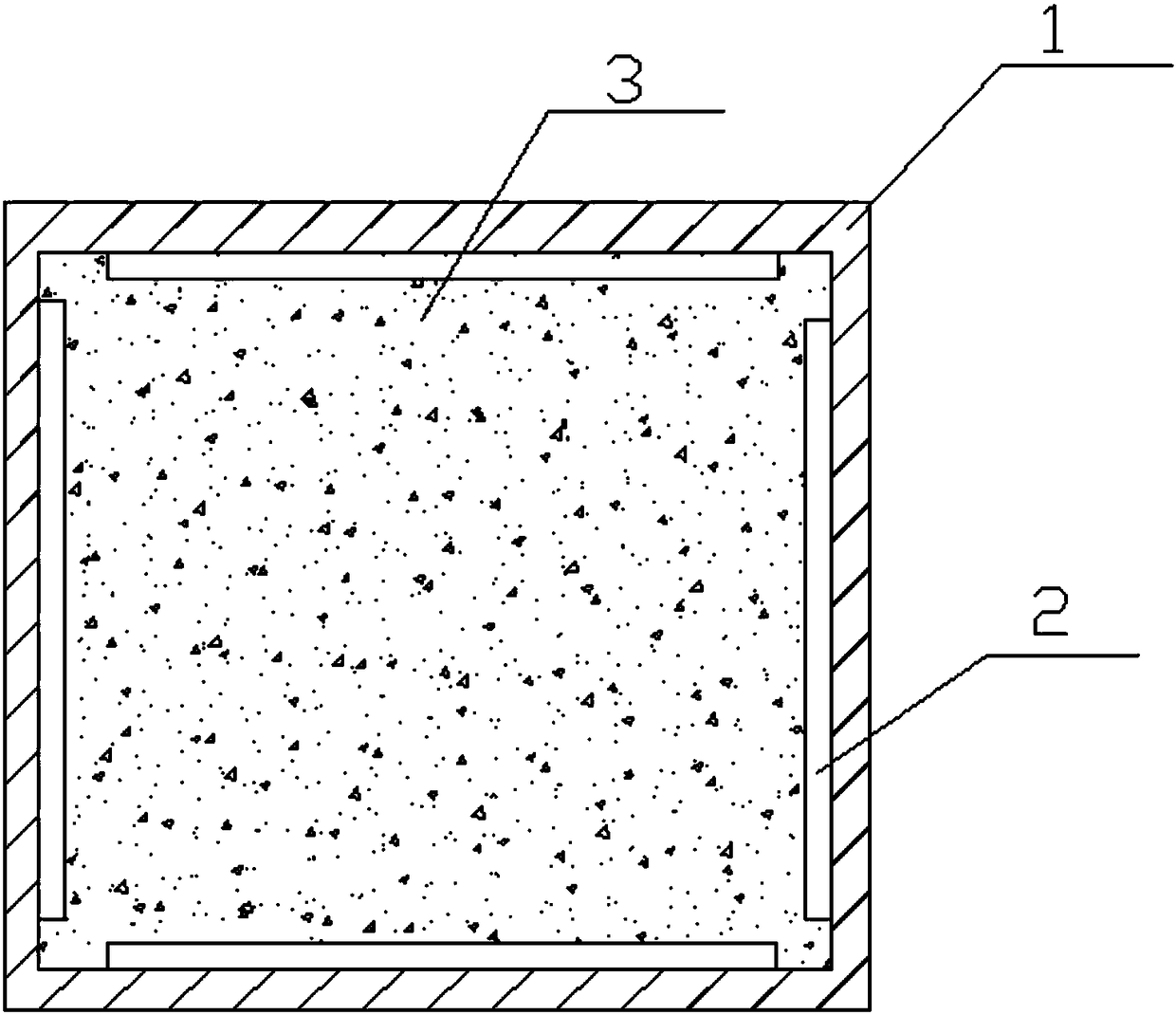

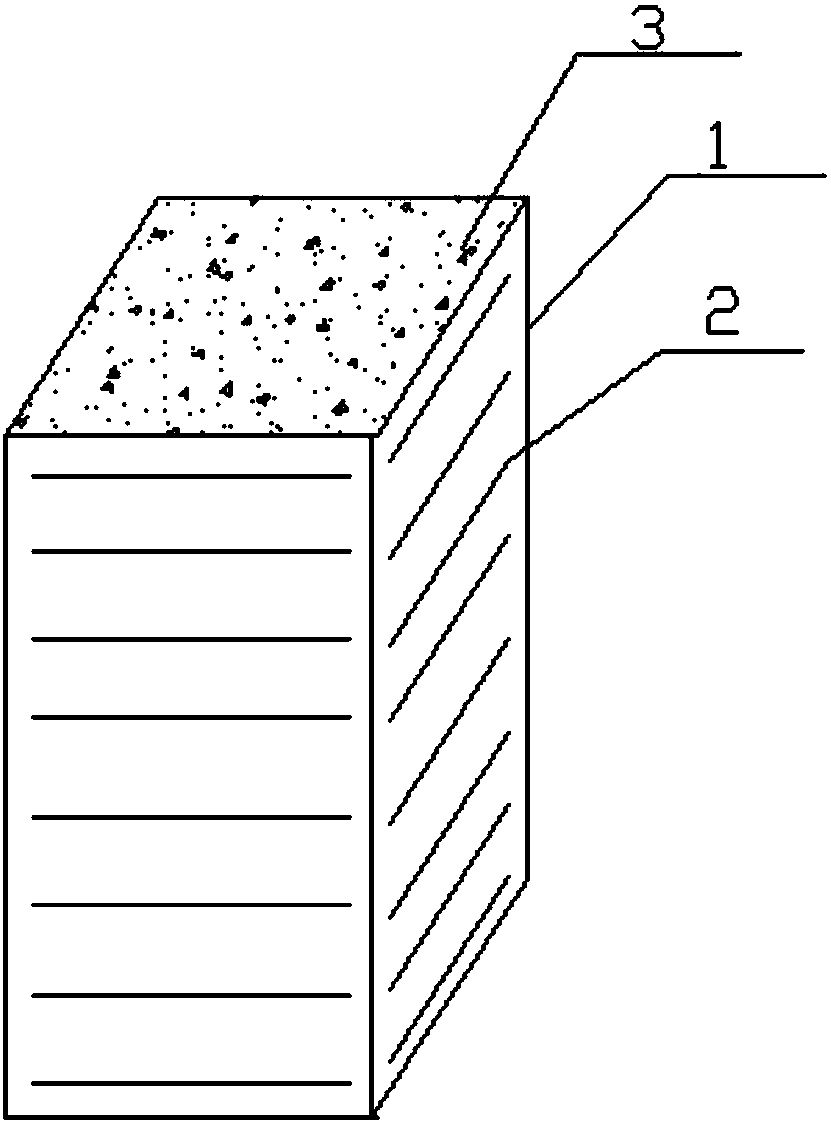

[0037] A new type of square steel tube concrete column, such as figure 2 and image 3 As shown, it includes built-in transverse stiffening steel bar 2, steel plate 1 and concrete 3, the steel plate surrounds the square steel pipe, the built-in transverse stiffening steel bar is transversely welded to the four inner walls of the square steel pipe, and the concrete is filled inside the square steel pipe.

[0038] The length of the built-in transverse stiffener is less than the width of the square steel pipe, and the length of the built-in transverse stiffener accounts for more than 90% of the width of the square steel pipe.

[0039] The interval between adjacent built-in transverse stiffeners on the same steel plate is 50mm to 100mm.

[0040] Among them, the concrete adopts the concrete with the strength grade of C25, C30 or C40. Among the materials used for pouring concrete, medium sand and gravel have a maximum particle size of 20mm. The water-cement ratio of the concrete i...

Embodiment 2

[0043]A new type of square steel tube concrete column specimens, the specimens are divided into two groups, the first group (Group A) has a total of 8 specimens, which are 2 ordinary square steel pipe concrete specimens with a steel plate thickness of 4mm and a steel plate thickness of 6 square concrete-filled steel tube specimens with 4mm built-in transverse stiffening bars (the spacing of the transverse stiffening bars is 50mm, 75mm and 100mm, the length of the transverse stiffening bars is 180mm, and the diameters of the bars are 4mm and 6mm respectively), the cross-sectional geometric dimensions are 200mm×200mm, The length-to-diameter ratio of the test piece is L / D=3, and the height of the test piece is 600mm. The second group (Group B) consists of 11 specimens, including 2 ordinary square concrete-filled steel tube specimens with a steel plate thickness of 6 mm and 9 square concrete-filled steel tube columns with built-in transverse stiffening bars with a steel plate thick...

Embodiment 3

[0045] A construction method of a novel square steel tube concrete column, comprising the following steps:

[0046] Step 1. Preparation of square steel pipe with built-in horizontal reinforcement: firstly, cut the material according to the design size of the steel plate, prepare four steel plates for welding each square steel pipe and steel bars with a length of 180mm, and then weld the steel bars horizontally with the steel plates according to different design spacings. Together, four steel plates are finally welded to form a square section, ensuring that the steel plate welded with transverse reinforcement is on the inner side of the square steel pipe, and steel plate samples and steel bar samples are reserved for material performance tests.

[0047] Step 2: prepare concrete;

[0048] Step 3: Place the square steel pipe prepared in step 1 on a horizontal surface, pour the concrete prepared in step 2 into the square steel pipe from the top of the square steel pipe, and vibrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com