Pentagonal arm frame, wet spraying machine, and manufacturing method of polygonal arm frame

A manufacturing method and polygonal technology, applied in the direction of construction, building structure, and building material processing, can solve the problems of large welding heat input, poor guarantee of cross-sectional size of pentagonal boom, shrinkage and deformation of both sides, etc., to achieve Reduce the difficulty of processing, reduce the input of heat, and reduce the effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

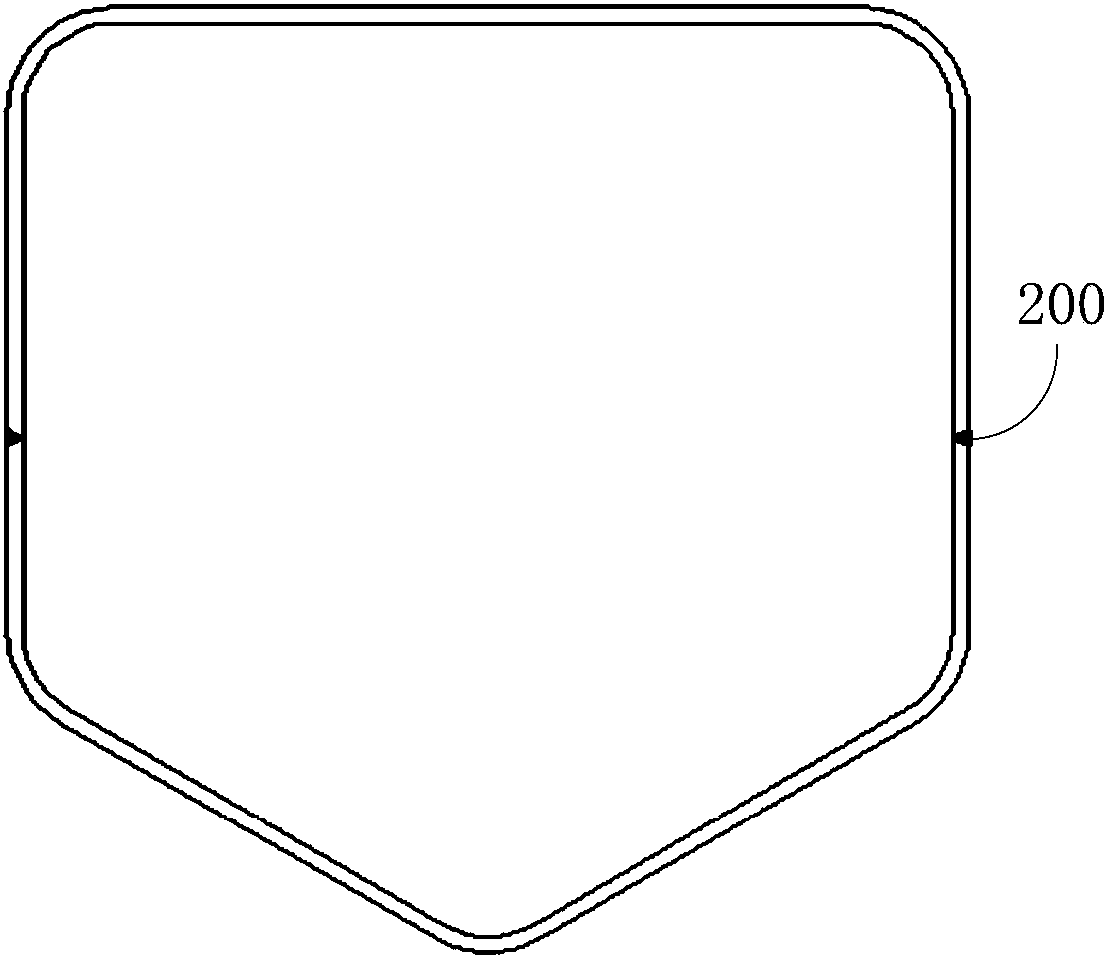

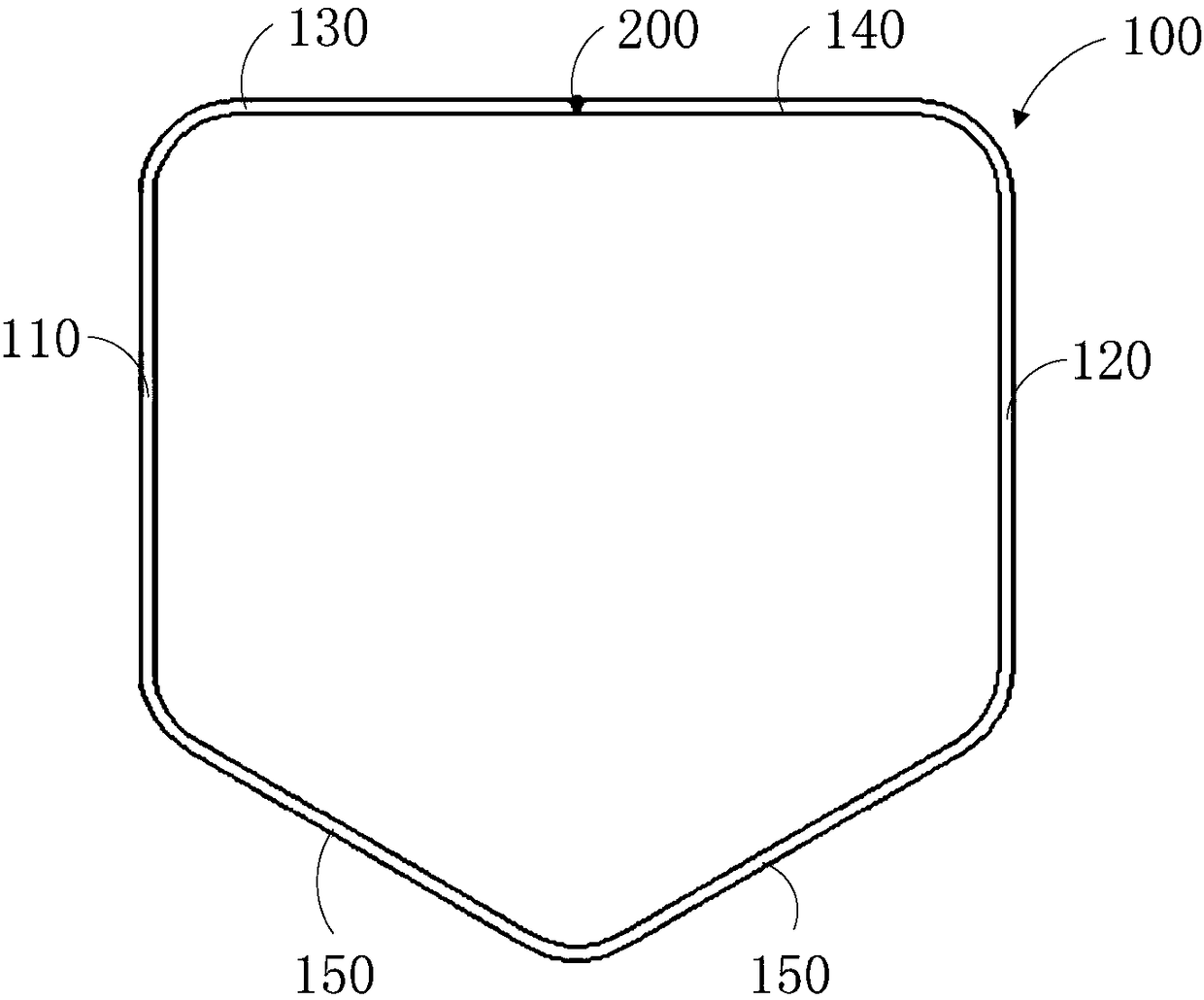

[0034] figure 2 The cross-sectional schematic diagram of the five-shaped arm frame provided for the embodiment of the present invention, as figure 1 As shown, the pentagonal jib provided by the embodiment of the present invention includes: the jib body 100, the jib body 100 is formed by bending a sheet, and the two ends of the bent sheet are connected by welding, and the welding formed by welding The slot 200 is located on the top plate of the boom body 100 .

[0035] Specifically, the jib body 100 includes a first side plate 110 and a second side plate 120, the first side plate 110 and the second side plate 120 are parallel to each other, the lower end of the first side plate 110 and the lower end of the second side plate 120 pass through The two inclined bottom plates 150 are connected, the upper end of the first side plate 110 is connected with the first top plate 130, the upper end of the second side plate 120 is connected with the second top plate 140, the first top pla...

Embodiment 2

[0040] An embodiment of the present invention provides a wet spray machine. The wet spray machine provided by the embodiment of the present invention includes the pentagonal arm provided in the first embodiment.

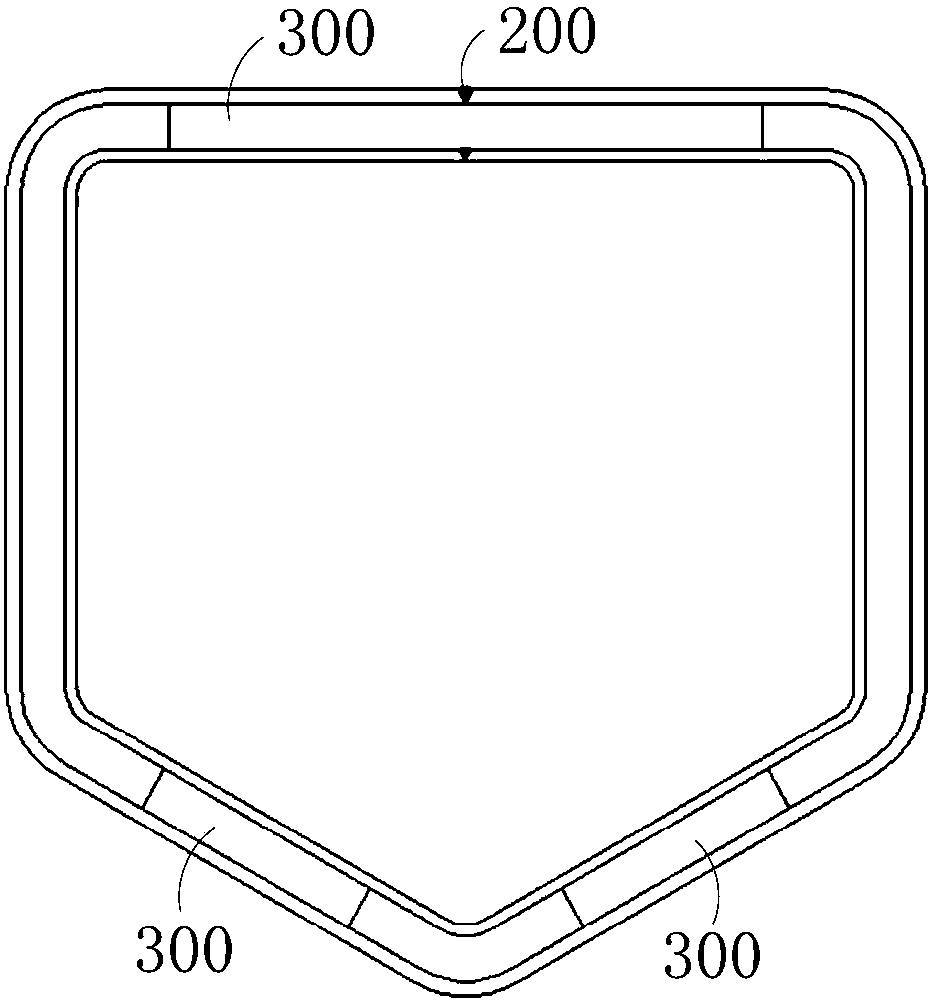

[0041] Specifically, the spray humidifier provided by the embodiment of the present invention includes at least two pentagonal arm frames provided in Embodiment 1. As shown in 3, the cross-sectional shapes of adjacent pentagonal arm frames are the same but different in size; the cross-sectional size One end of the smaller pentagonal arm extends into the larger pentagonal arm, the other end is located outside, and the outer end is provided with a nozzle, two pentagonal arms form a telescopic arm, two The gap between the pentagonal arms is provided with a middle slider 300, and the middle slider 300 prevents mutual friction between the two pentagonal arms.

[0042] In the process of using the wet spray machine, the telescopic arm is extended or contracted according to ...

Embodiment 3

[0044] An embodiment of the present invention provides a method for manufacturing a polygonal boom.

[0045] The polygonal arm frame manufacturing method provided by the embodiment of the present invention is used to manufacture the above-mentioned pentagonal arm frame, comprising: bending the plate into a polygon, and the interface of the plate is located on the side of the polygon; welding.

[0046] Specifically, use a bending machine to bend a plate into a pentagon, and the side plates at both ends of the bent plate can be spliced into a pentagonal side, and then, the two ends of the bent plate are welded Connected in a way to form a pentagonal arm.

[0047] Further, the two ends of the sheet are bent first, and then the middle of the sheet is bent.

[0048] Specifically, first use the bending knife 400 to bend the first top plate 130 and the first side plate 110 at one end of the plate, and bend the second top plate 140 and the second side plate 120 at the other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com