Automated 'stance type' composite material manual lay-up workshop

A composite material, station type technology, applied in the field of automatic "station type" composite material manual layup workshop, can solve the problems of increasing labor intensity, increasing operation complexity, high risk of wrong operation, and reducing invalid operation time. , to achieve the effect of flexibility, simplify the degree of confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

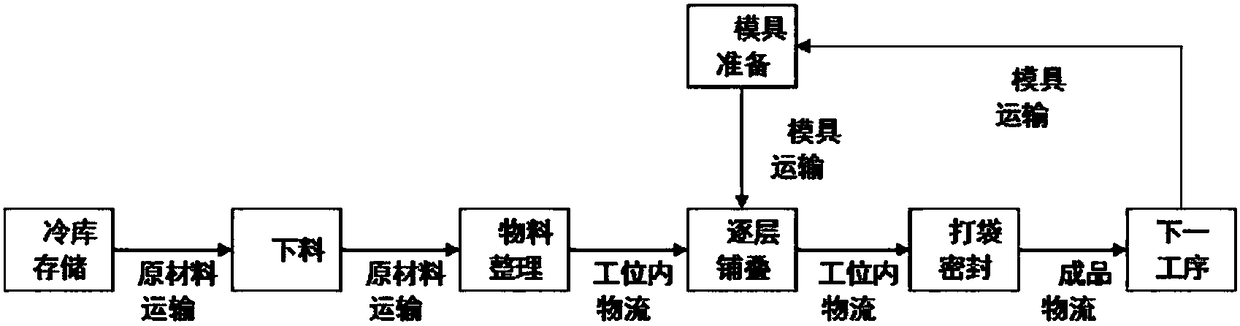

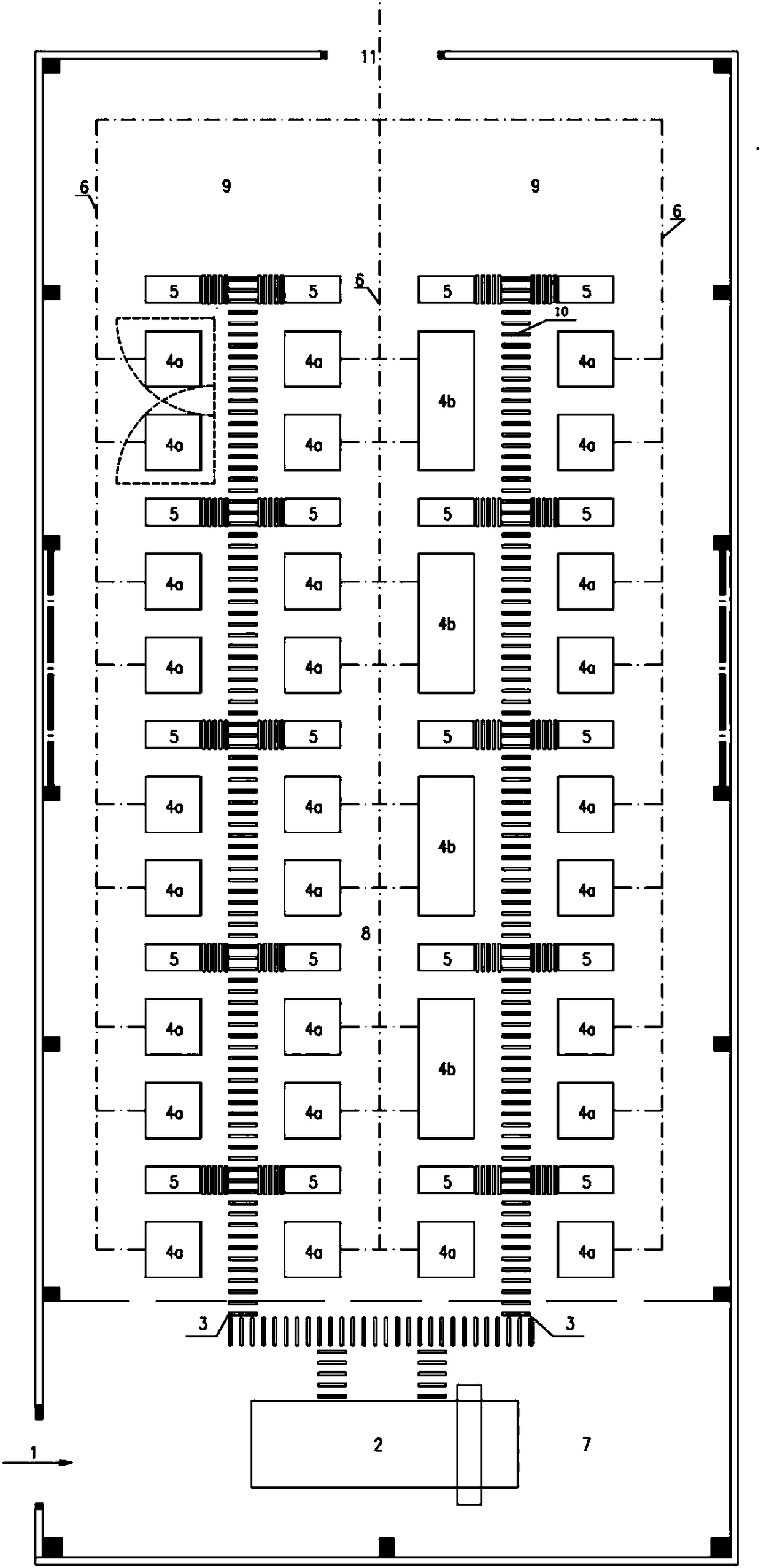

[0018] See attached figure 2 As shown, this kind of automatic "stand-up" composite material manual laying workshop is characterized in that: the workshop entrance 1 is set at the front of the workshop, the workshop exit 11 is set at the rear, and the unloading machine 2 is set at the front of the workshop to transport The machine 3 is docked with the unloading machine 2, and the conveyor 3 is connected to 2 to 4 raw material conveying chains 10 arranged side by side from the front to the rear of the workshop. On both sides of each raw material conveying chain 10, a mold conveying chain 6 is arranged, and the mold The conveyor chain 6 converges at the rear of the workshop and is adjacent to the workshop exit 11. A station is set between the raw material conveyor chain 10 and the mold conveyor chain 6, and a material temporary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com