A construction method for strengthening the core soil and glass fiber anchor rods of shallow-buried collapsible loess tunnels

A technology of collapsible loess and construction methods, which is applied in tunnels, installation of bolts, earthwork drilling and mining, etc., can solve problems such as intrusion of support structures in tunnels, instability of surrounding buildings, slow construction progress, etc., and achieve improvement Soil compression and shear resistance, speed up construction progress, and reduce engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

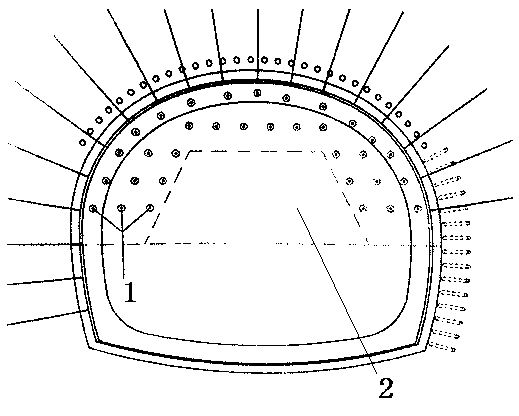

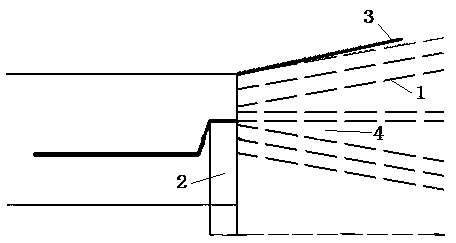

[0028] A construction method for reinforcing the core soil of a shallow-buried collapsible loess tunnel with glass fiber anchor rods, comprising the following steps:

[0029] (1) Construction preparation

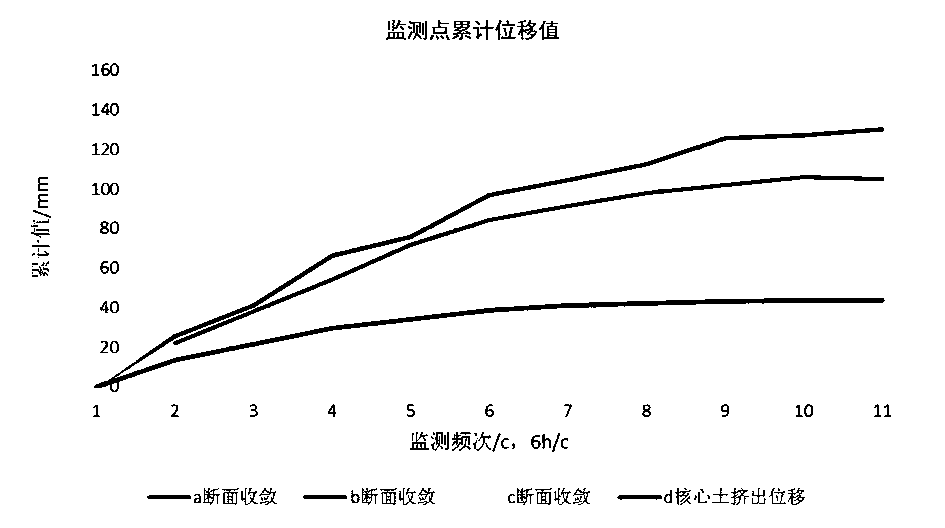

[0030] ①Preparation of tunnel displacement monitoring equipment with up to standard accuracy. The tunnel displacement monitoring equipment includes digital display convergence gauge, level gauge and sliding longitudinal micrometer;

[0031] ②Prepare the small conduit 3 for advance grouting. The small conduit 3 for advance grouting is a hot-rolled seamless steel pipe of Φ42mm, where Φ indicates a diameter, length 4.5m, and wall th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com