A Pilot-operated Hydraulic Safety Valve

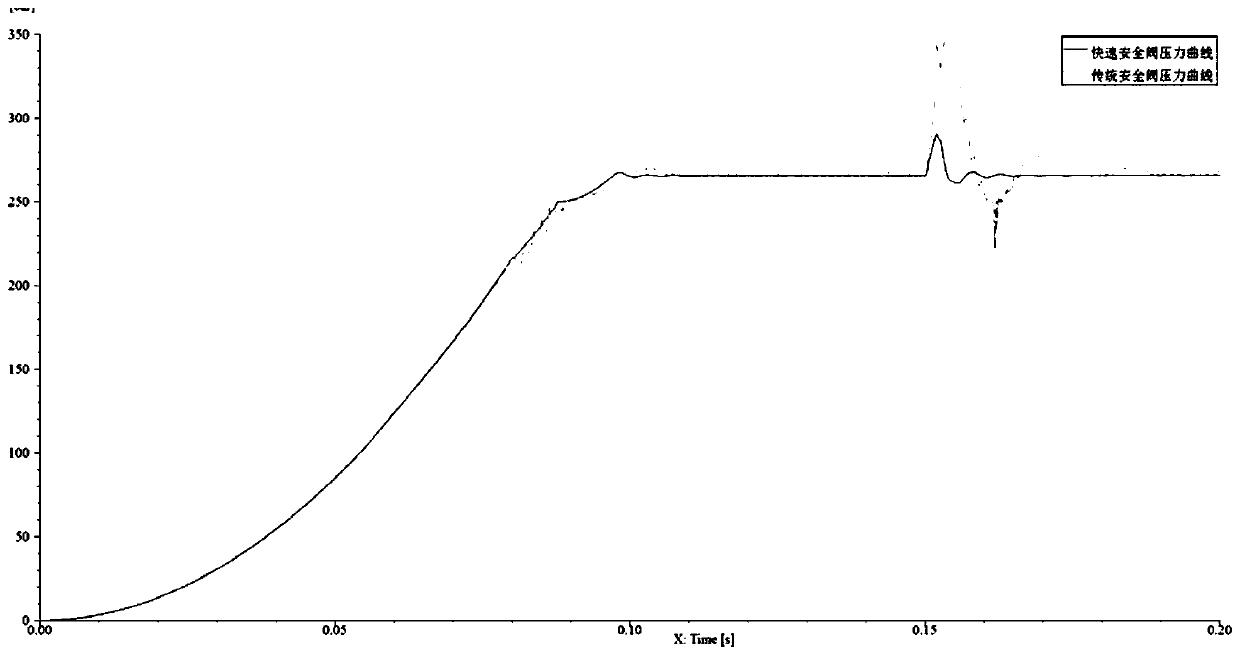

A safety valve, pilot-operated technology, applied in the hydraulic field, can solve the problems of hydraulic system damage, damage to hydraulic components and measuring instruments, and reduced accuracy of components and instruments, so as to reduce the time of pressure shock, the system pressure adjustment is stable and fast, and the Amplitude effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

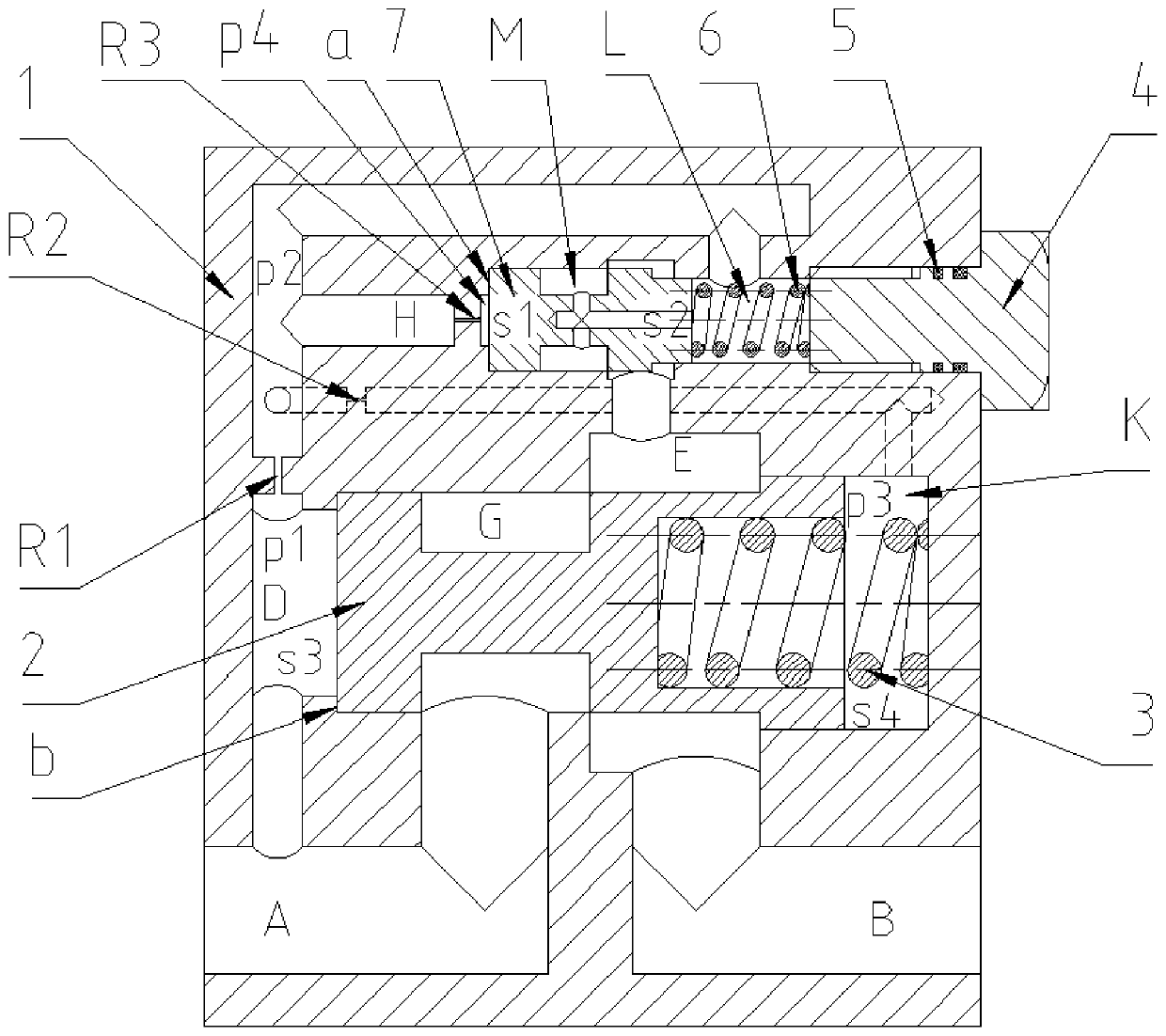

[0016] A pilot-operated hydraulic safety valve, including a housing 1, a main valve core 2, a main spring 3, a pressure regulating knob 4, a pressure regulating spring 6, and a pilot valve core 7; Pipe B for oil return; housing 1 has an inner cavity for installing main spool 2 and pilot spool 7, oil inlet chamber A and oil return chamber B, main spool 2 and pilot spool are installed in housing 1 Among them, the main spool 2 forms cavity D between the left end surface and the housing, the K cavity is formed between the right end surface of the main spool 2 and the housing, and the G cavity is set between the main spool 2 and the oil inlet chamber A. An E cavity is formed between the spool 2 and the oil return cavity B, and a main spring 3 is provided between the right end surface of the main spool 2 and the casing; an L cavity is formed between the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com