Profiled seed guider

The technology of a seed guide and a seed guide tube, which is applied in the field of profiling seed guides, can solve problems such as poor adaptability, large lateral size, and complicated sowing single structure, and achieve straight seed rows, accurate plant spacing, and accurate seed placement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

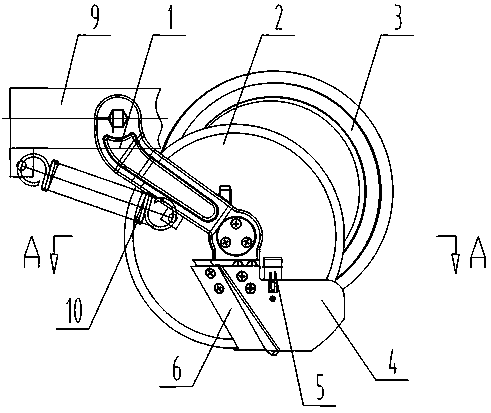

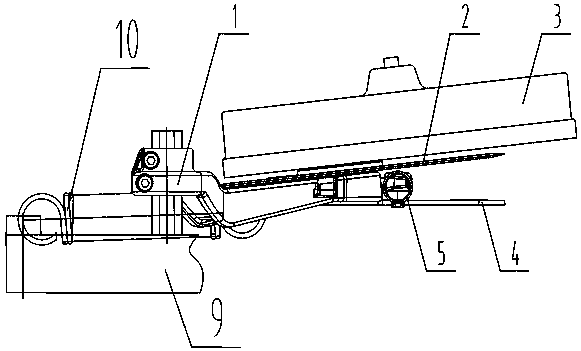

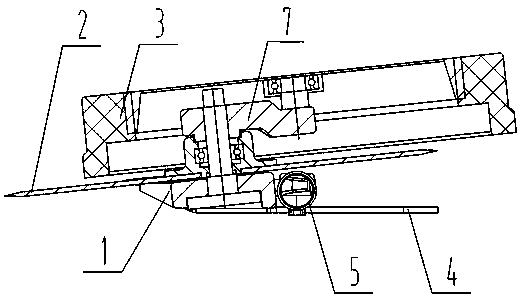

[0016] Such as figure 1 , figure 2 , image 3 As shown, a schematic diagram of the specific embodiment of the profiling seed guide of the present invention is provided, including a ditching disc 2, a profiling wheel 3, a seed introduction tube 5, and a single beam 9. The profiling wheel 3 is arranged on the The outer side of the ditching disc 2 also includes a support arm 1, a soil retaining wall 4, a soil retaining shovel 6, and a pre-tensioned tension spring 10. A pre-tightened extension spring 10 is arranged obliquely, the rear end of the pre-tightened extension spring 10 is hooked to the middle position of the support arm 1, the front end of the pre-tightened extension spring 10 is attached to the front end of the single beam 9, and the rear end of the support arm 1 supports A support shaft is arranged on the seat, and a ditching disc 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com