Rotating disc type automatic closing machine

A can sealing machine and rotary table technology, applied in the field of rotary table automatic can sealing machines, can solve the problems of low degree of automation, poor sealing effect, complicated operation, etc., and achieve the effect of high degree of automation, high work efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

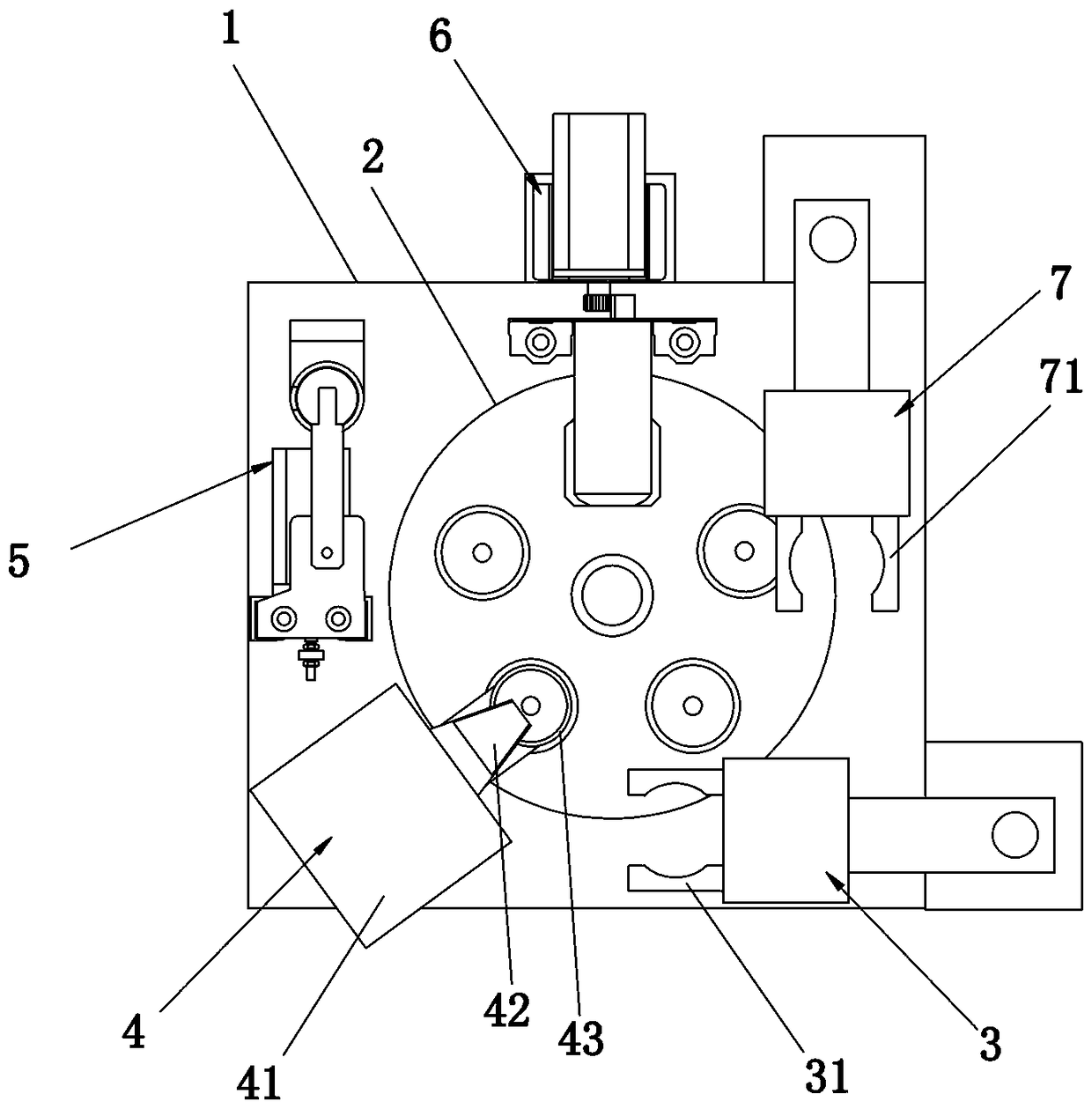

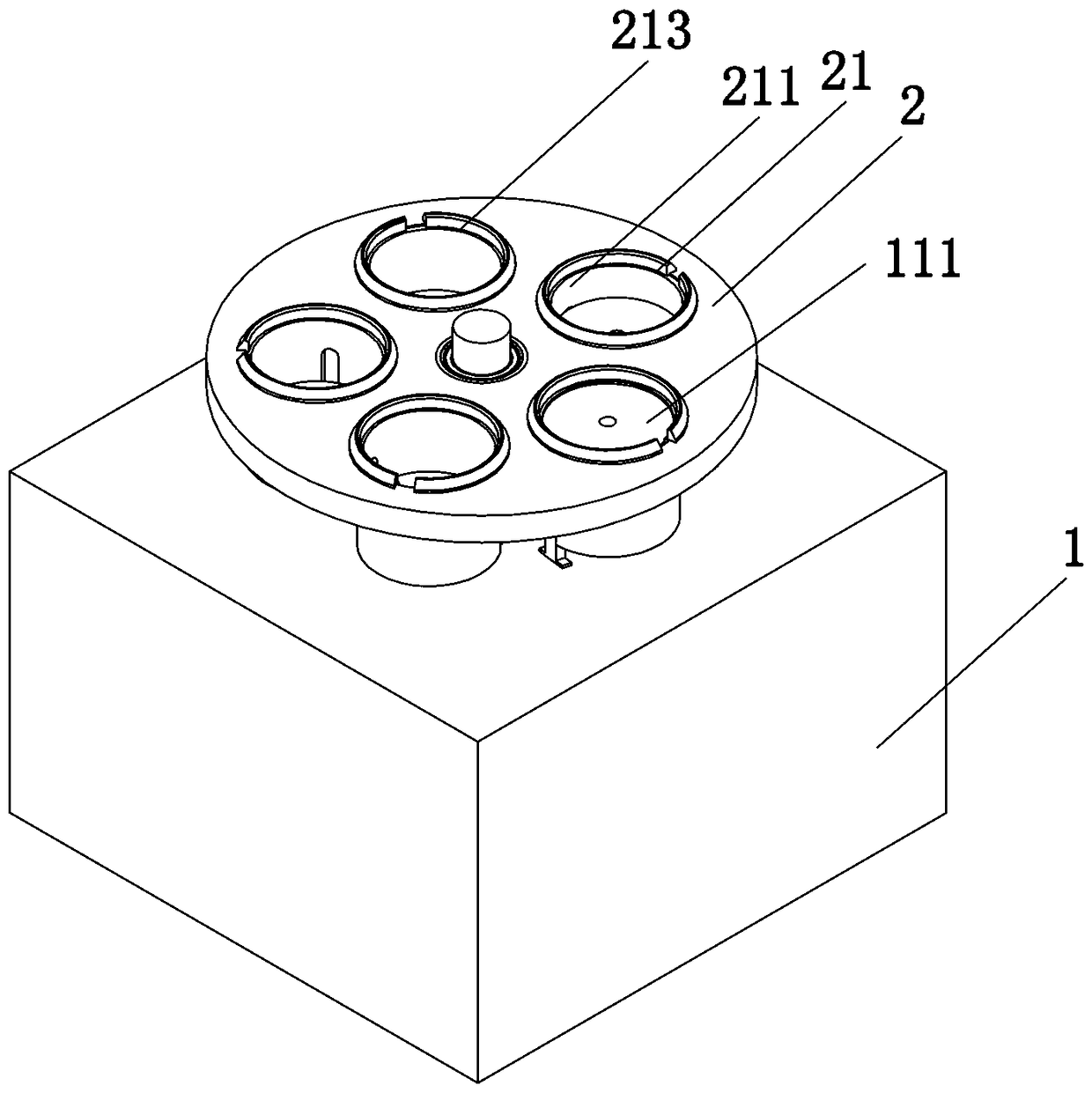

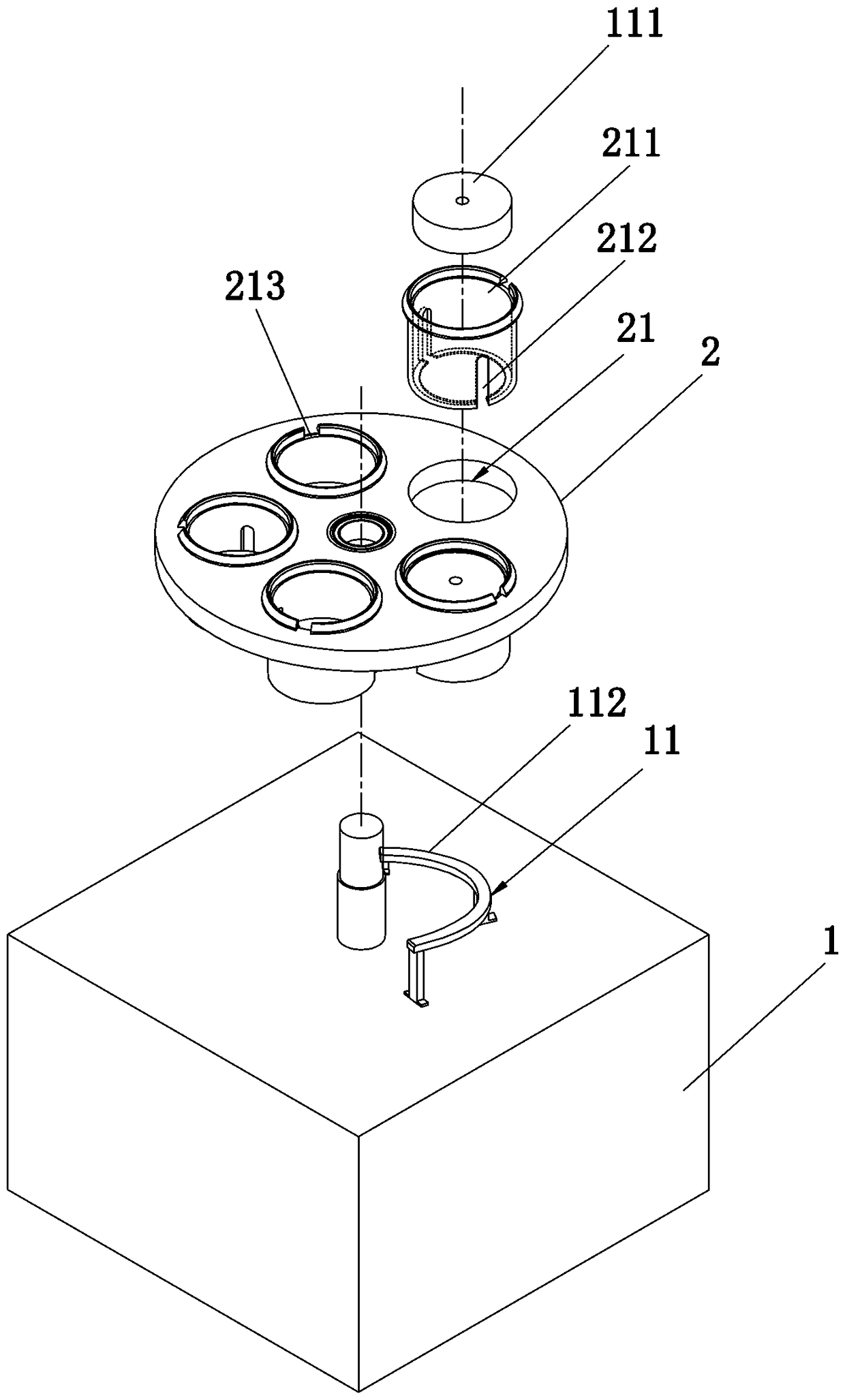

[0021] refer to figure 1 , figure 2 and image 3 , a turntable type automatic seaming machine, including a workbench 1 and a turntable 2, the turntable 2 is rotatably arranged on the workbench 1, and the workbench 1 is arranged with a plurality of stations 21 around the turntable 2, and the turntable 2 is at each station 21 is provided with a storage tank 211 for placing the tank body, and the bottom of the turntable 2 is provided with a lifting mechanism 11 for raising the tank body in the storage tank 211; the lifting mechanism 11 includes a pad 111 and a spiral track 112. All can move up and down in the groove 211 and be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com