Automatic labeling machine

A labeling machine, automatic technology, applied in the direction of labeling machine, labeling, packaging, etc., can solve the problems of production efficiency, lack of adjustment function, limit and other problems, and achieve the effect of improving accuracy, fast action and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

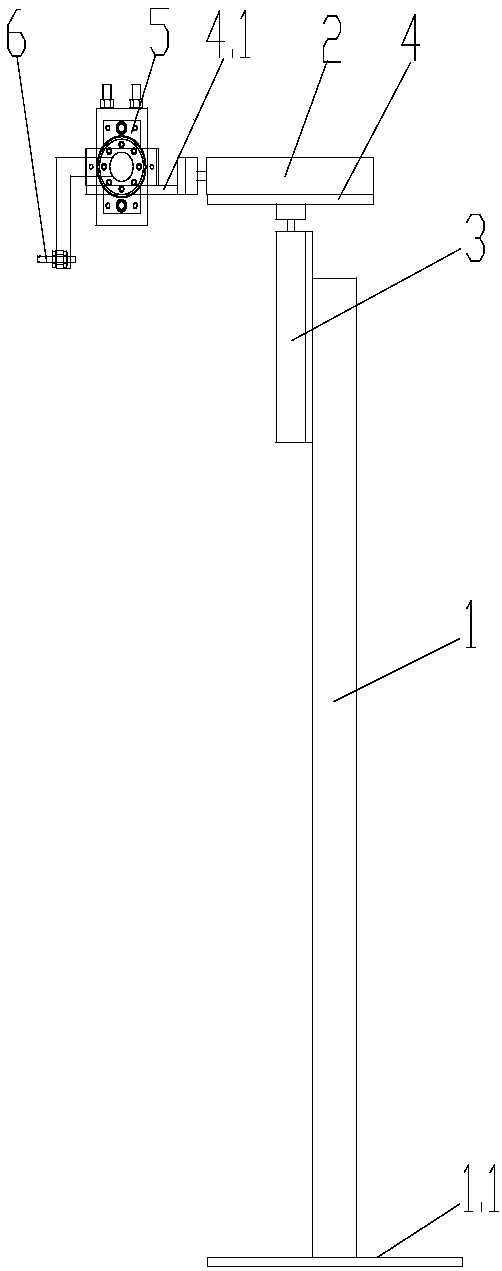

[0012] Embodiment 1: as figure 1 The shown automatic labeling machine includes a column 1, a lifting cylinder 3, a horizontal cylinder 2, a swing cylinder 5, and a vacuum suction cup 6. The lifting cylinder 3 is vertically arranged on the top of the column 1, and the piston rod of the lifting cylinder 3 is upward , the horizontal cylinder 2 is horizontally arranged at the front end of the piston rod of the lifting cylinder 2, the horizontal cylinder 2 is connected with the piston rod of the lifting cylinder 3 with the first connecting plate 4, the front end of the piston rod of the horizontal cylinder 2 is provided with a second connecting plate 4.1, and the swing cylinder 5 is fixed on the connection plate 4.1, and the vacuum suction cup 6 is set at the end of the L-shaped output shaft of the swing cylinder 5. The L-shaped output shaft increases the swing radius, which is convenient for labeling processing of different packaging containers, and changes the The swing position ...

Embodiment 2

[0013] Embodiment 2: as figure 1 The shown automatic labeling machine includes a column 1, a lifting cylinder 3, a horizontal cylinder 2, a swing cylinder 5, and a vacuum suction cup 6. The lifting cylinder 3 is vertically arranged on the top of the column 1, and the piston rod of the lifting cylinder 3 is upward , the horizontal cylinder 2 is horizontally arranged at the front end of the piston rod of the lifting cylinder 2, the horizontal cylinder 2 is connected with the piston rod of the lifting cylinder 3 with the first connecting plate 4, the front end of the piston rod of the horizontal cylinder 2 is provided with a second connecting plate 4.1, and the swing cylinder 5 is fixed on the connection plate 4.1, and the vacuum suction cup 6 is set at the end of the Z-shaped output shaft of the swing cylinder 5. The Z-shaped output shaft increases the swing radius, which is convenient for labeling processing of different packaging containers, and changes the The swing position ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap