Umbrella frame turntable of lens coating machine

A coating machine and umbrella stand technology, used in sputtering coating, ion implantation coating, vacuum evaporation coating, etc. Convenient, fast and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

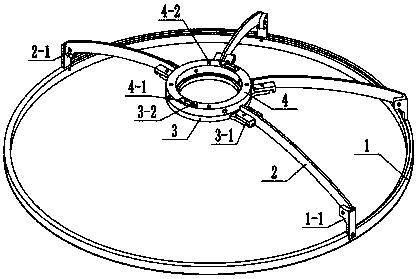

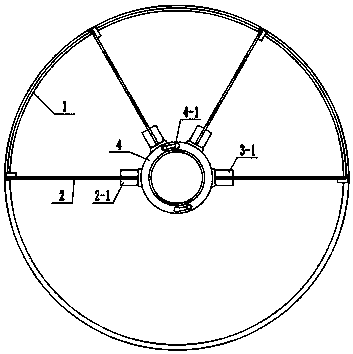

[0011] Depend on figure 1 , figure 2 Known, a kind of lens coating machine umbrella stand turntable of the present invention is made up of pot body fixed ring 1, movable connecting arm 2, lower connecting seat 3, upper connecting seat 4, and described pot body fixing ring 1 upper circumference is provided with pot body Lifting lugs 1-1, the four pot body lifting lugs 1-1 are evenly distributed on the 180-degree position of the circumference of the pot body fixing ring 1, and the angle between two adjacent pot body lifting lugs 1-1 is 60 degrees. The lower connecting seat 3 is provided with lower seat lifting lugs 3-1, four lower seat lifting lugs 3-1 are distributed on the outer side of the lower connecting seat 3 at 180 degrees, and the angle between two adjacent lower seat lifting lugs 3-1 is 60 degrees, one end of the four movable connecting arms 2 is connected with the lifting ear 1-1 of the pot body, and the other end is connected with the lifting ear 3-1 of the lower s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap