Treatment method and foundation structure of deep foundation

A treatment method and foundation technology, which can be applied in foundation structure engineering, earthwork drilling, directional drilling, etc., can solve problems such as poor overall stability of support piles and damage to superstructures, so as to avoid soil subsidence, avoid damage, and strengthen the overall The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

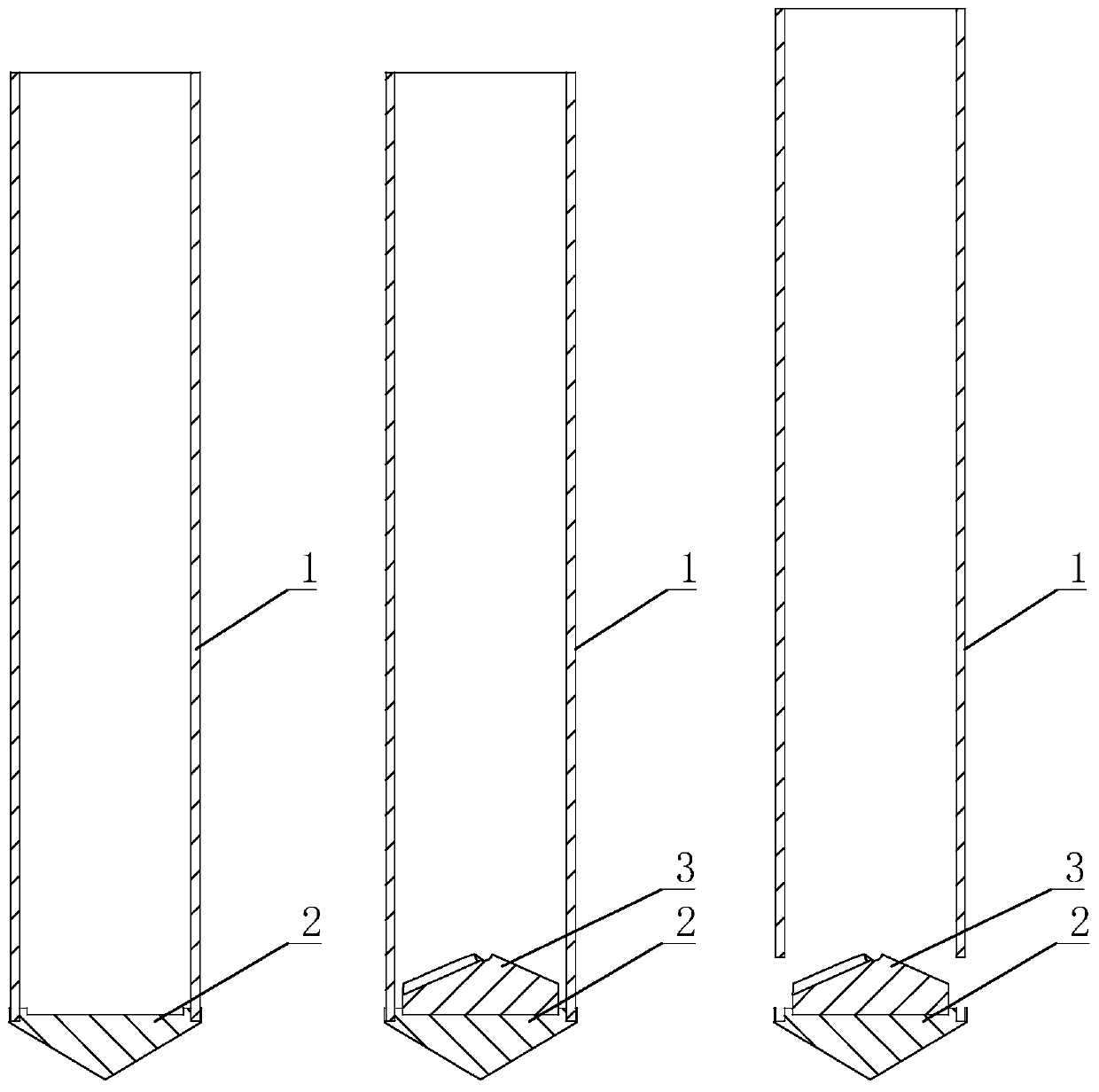

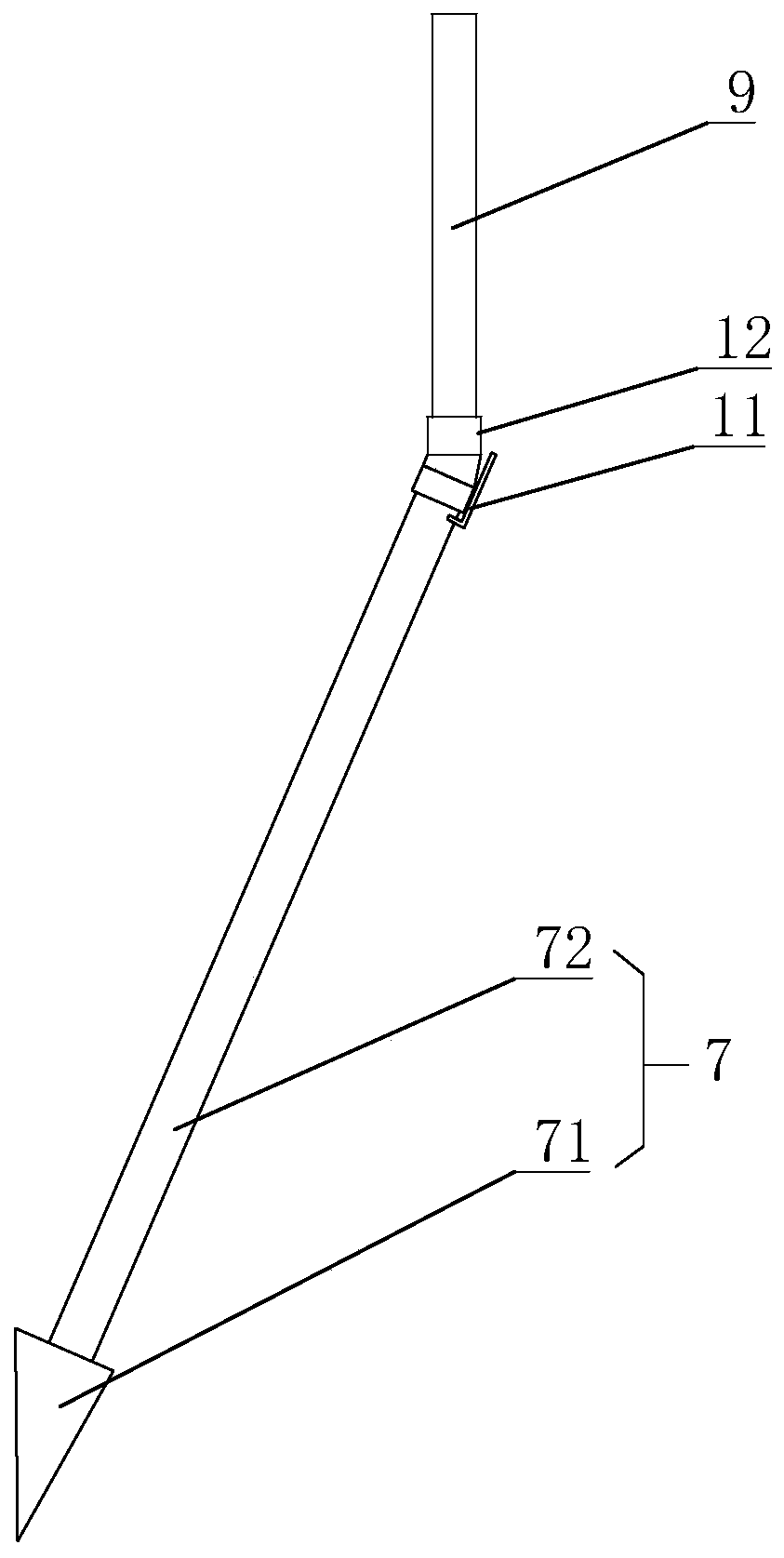

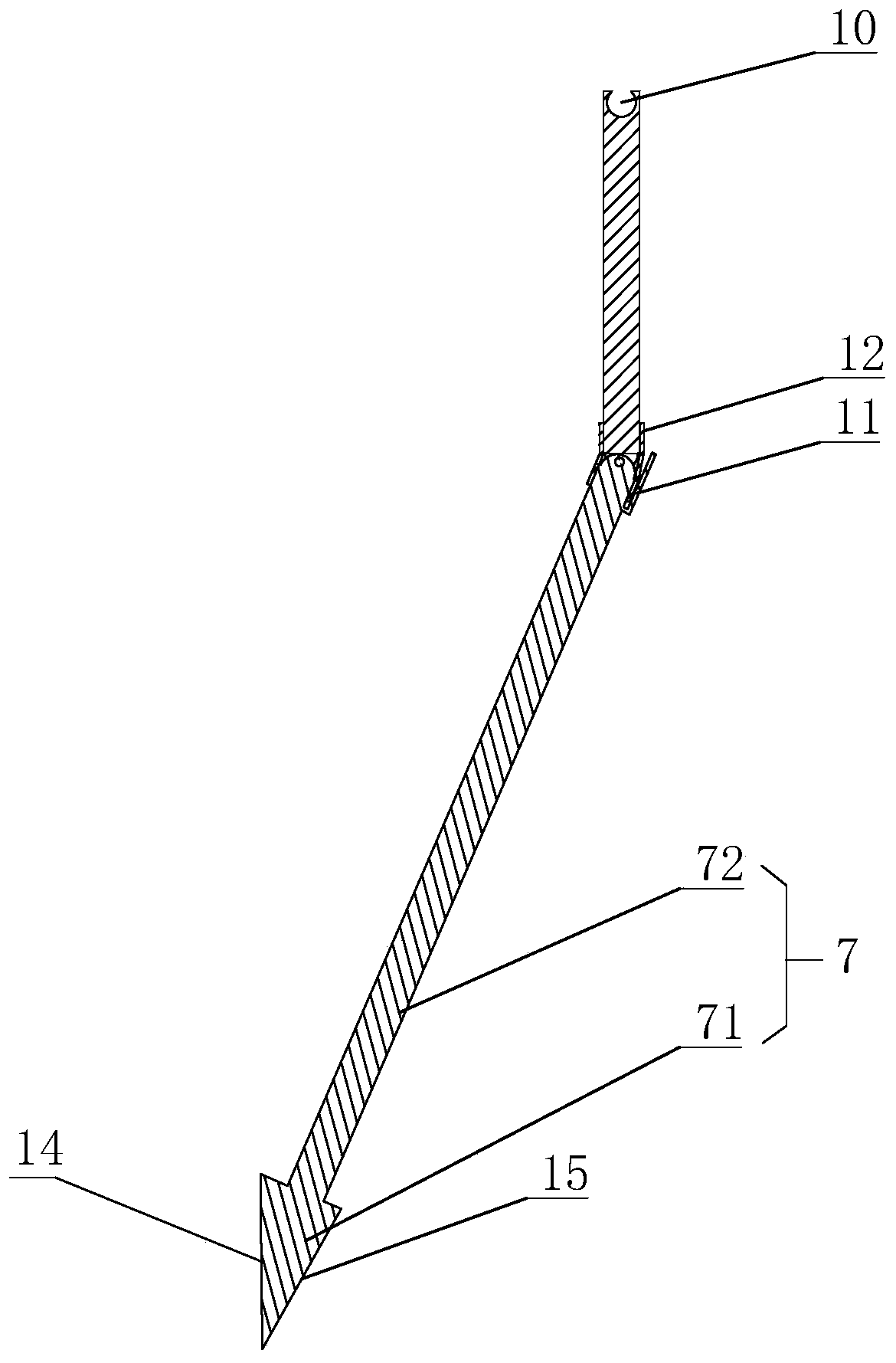

[0058] Embodiment one: a kind of treatment method of deep foundation, comprises the following steps:

[0059] refer to figure 1 , step 1, the steel pipe 1 and the pile point 2 against the lower end surface of the steel pipe 1 are sunk into the ground together, the pile point 2 is set on the lower end of the steel pipe 1 and can be separated from the steel pipe 1, so that the lower end surface of the steel pipe 1 reaches the design elevation , the pile point 2 forms a seal on the lower end of the steel pipe 1;

[0060] Step 2, put the guide block 3 into the lower end of the steel pipe 1, the bottom of the guide block 3 can be made of beryllium bronze material, the inside of the pile tip 2 is provided with a card slot matching the bottom of the guide block 3, and the end of the guide block 3 facing the pile tip 2 Engaged with the pile tip 2, the guide block 3 is tapered as a whole, the guide block 3 is coaxial with the steel pipe 1 and its tip faces the entrance of the steel pi...

Embodiment 2

[0076] Embodiment two: if Figure 10 As shown, a deep foundation treatment method differs from the first embodiment in that the number of connecting piles 5 around the supporting piles 6 is six, and the projections of the supporting piles 6 on the ground are arranged in an equilateral triangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com