Mounting structure for all-aluminum wallboard

A technology for installing structures and wall panels, which is applied in building construction, covering/lining, construction, etc., can solve the problems of non-recyclability, hazards, excessive formaldehyde, etc., and achieve the advantages of reducing installation difficulty, strong operability, and shortened use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

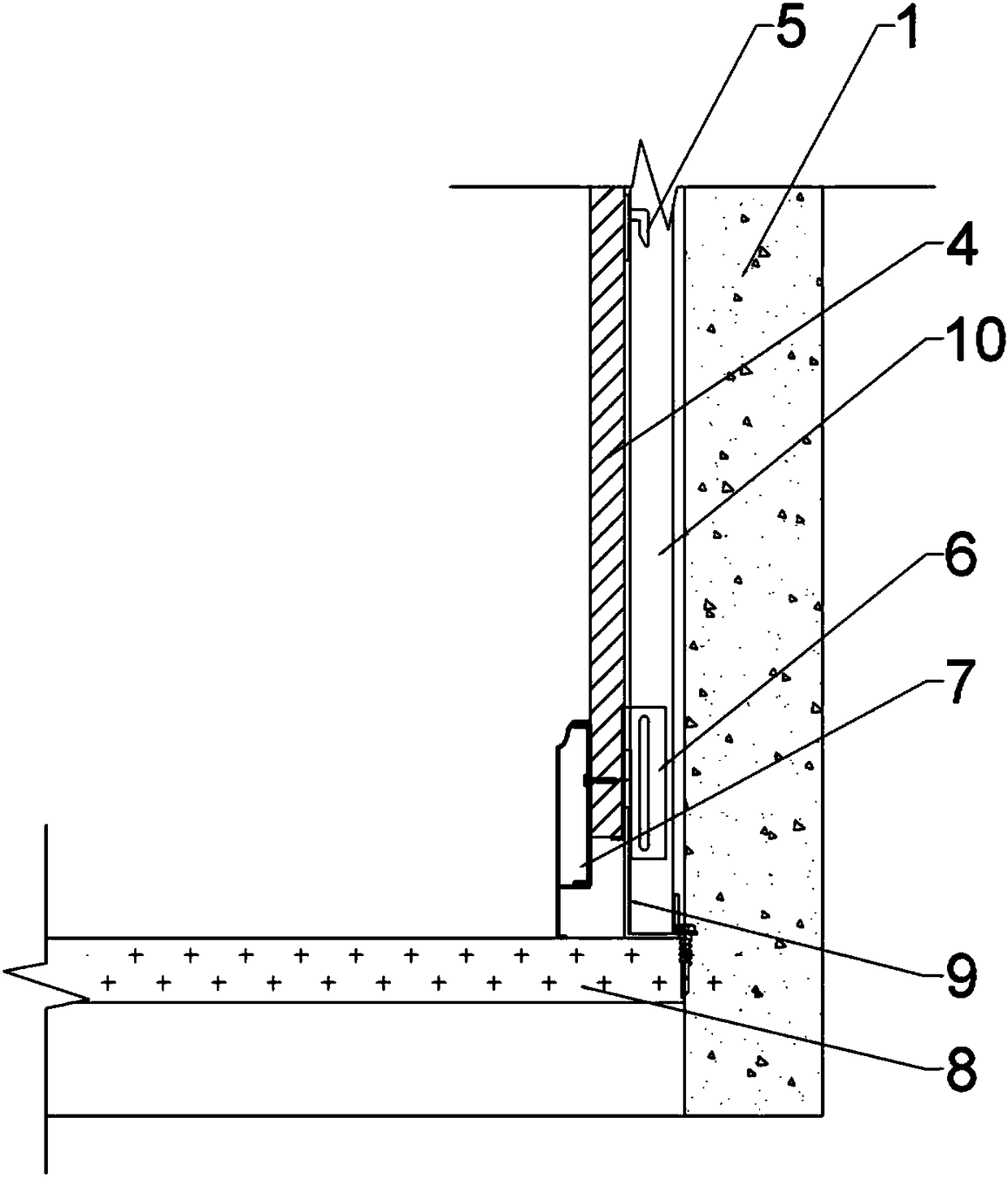

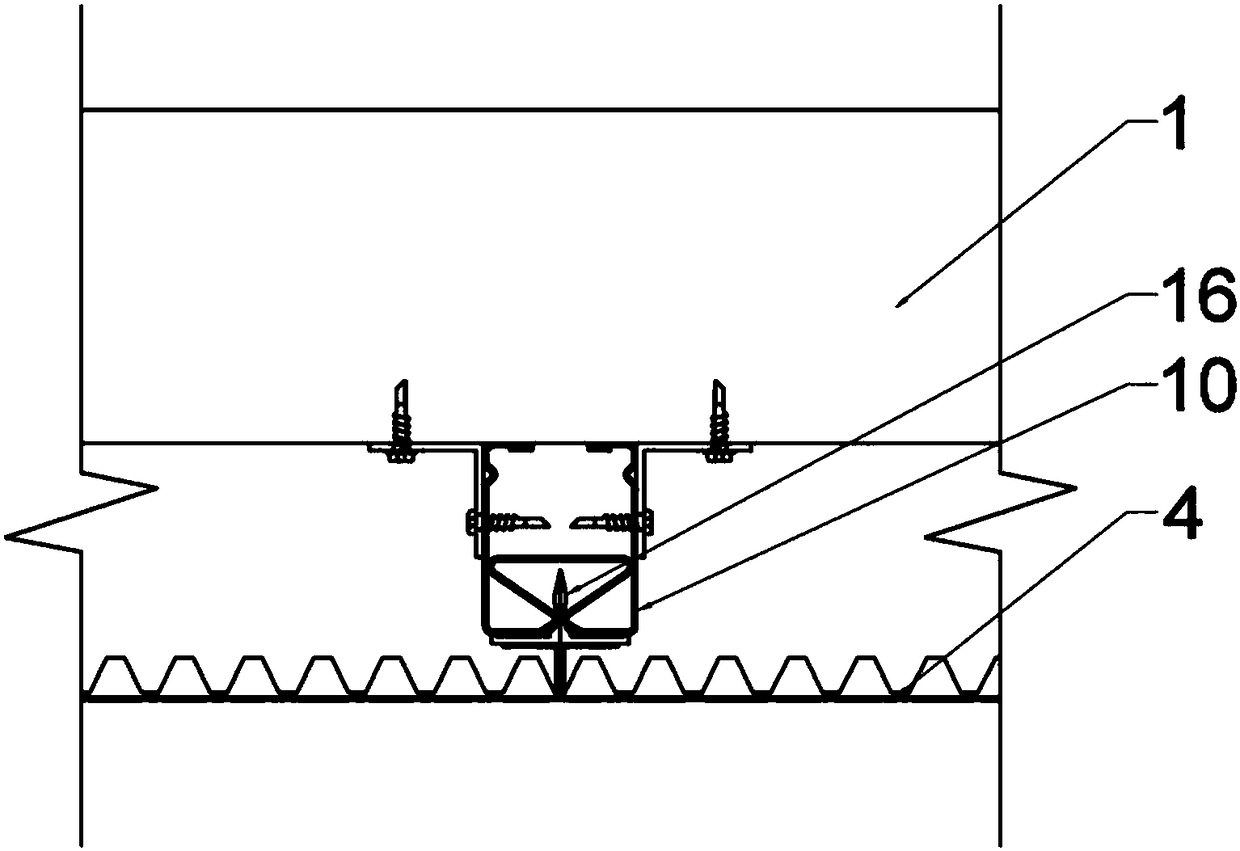

[0034] Basic as attached Figure 1-2 Shown: An installation structure of an all-aluminum wall panel, including the skirt waist installation part, the ground closing part and the seamless installation part.

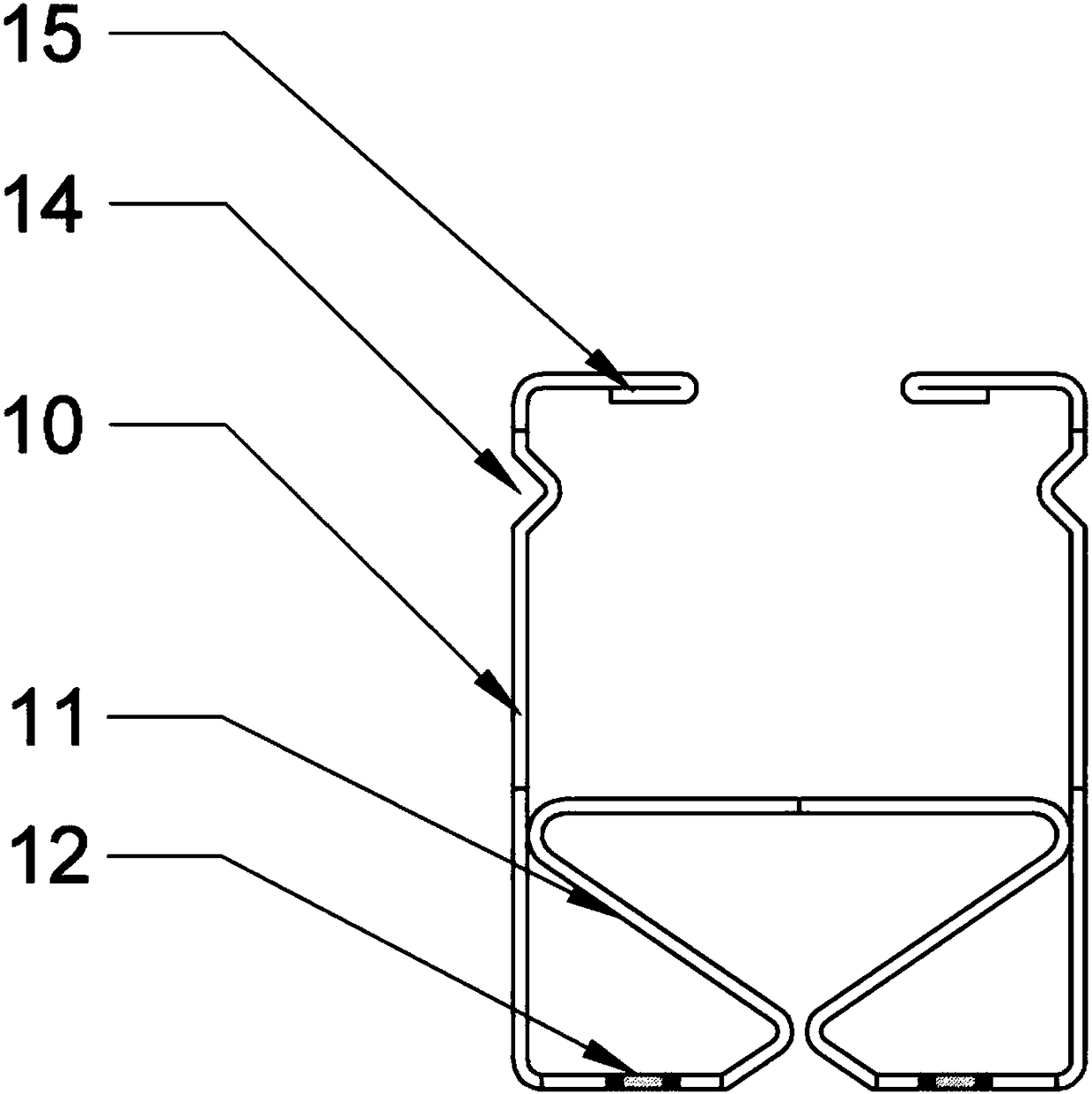

[0035]The closing part of the ground 8 includes steel keels, pendants 5, tow pieces 6, baseboards 7 and ground keels 9 arranged in sequence from top to bottom. The steel keels are fixed on the wall 1 and installed at the edge of the wall panel 4. It is used to fix and support the wall panel 4, and at the same time, it can avoid the problem that the flat part of the wall panel 4 is in direct contact with the rough wall surface, which is inconvenient for installation. The drag piece 6 is U-shaped as a whole, and its two side walls are provided with strip grooves. The bottom plate of the drag piece 6 protrudes outwards to form a support portion. One end extends to the middle of the wall panel dragging piece 6; the hanging piece 5 includes a connecting hook and a connecting p...

Embodiment 2

[0042] The difference from Example 1 is only that: the corrugated board layer and the aluminum board layer of the wall panel are fixed by hot melt adhesive, and the thickness of the corrugated board layer gradually decreases from top to bottom, and between the wall board and the aluminum board layer A number of cavities are formed between them. The cavities are vertically arranged and both ends are connected. The lower ends of the cavities are equipped with sealing iron rings and sealing plugs that slide and fit with the sealing iron rings. The sealing plugs are made of magnets. Usually, the sealing plugs and the sealing iron rings The lower end of the corrugated board layer is sealed by suction, and some of the cavities are filled with aluminum sulfate solution, and some of the cavities are filled with sodium hydroxide solution; , the sealing plug and the corrugated board layer are easy to absorb heat and heat up, the sealing plug quickly reaches the Curie temperature and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com